A Stepped Viscous-Frictional Damper

A friction damper and viscous technology, which is applied in the field of hierarchical viscous-friction dampers, can solve the problems of low energy dissipation capacity, poor fatigue performance, insufficient energy dissipation capacity of viscous dampers, etc., and achieve energy dissipation capacity High, improve fatigue performance, good effect of frictional energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

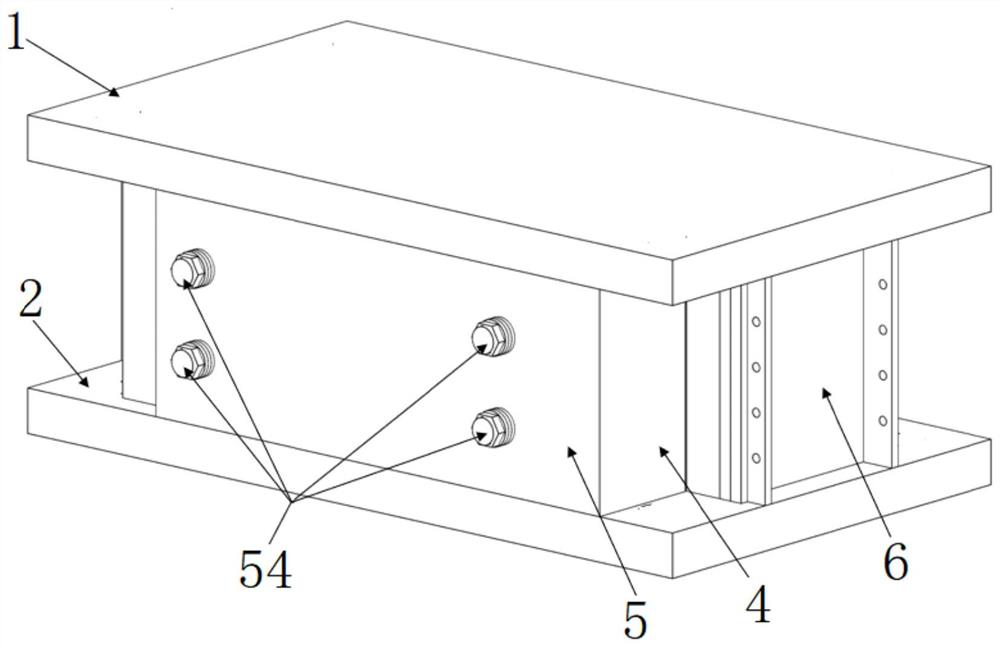

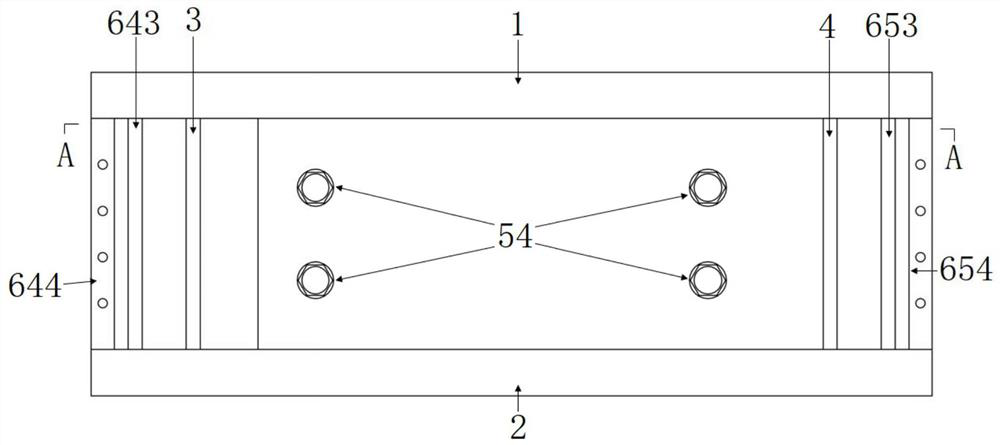

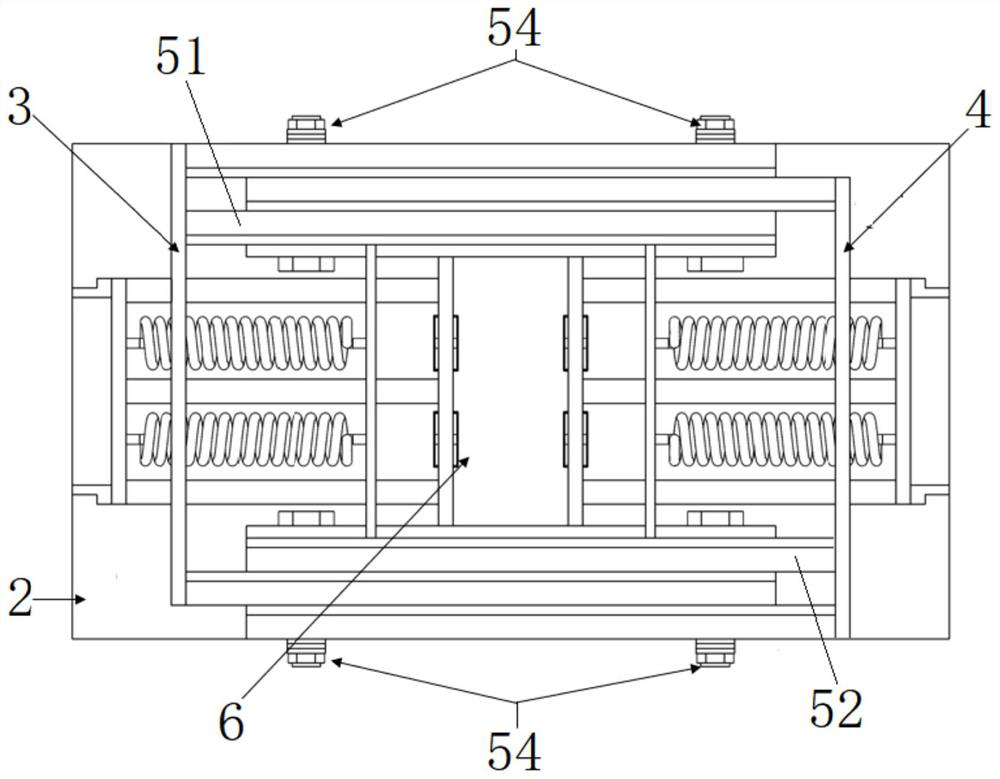

[0065] as attached Figure 1-13 As shown, this embodiment provides a stepped viscous-friction damper, including a top plate 1, a bottom plate 2, a first end plate 3, a second end plate 4 and a composite damper body; the top plate 1 and the bottom plate 2 are arranged in parallel , the top plate 1 is horizontally spaced above the bottom plate 2; the first end plate 3 and the second end plate 4 are vertically arranged between the top plate 1 and the bottom plate 2 in parallel, and the upper ends of the first end plate 3 and the second end plate 4 are aligned with the The two ends of the top plate 1 are welded and fixed, and the lower ends of the first end plate 3 and the second end plate 4 are respectively welded and fixed with the two ends of the bottom plate 2; the top plate 1, the bottom plate 2, the first end plate 3 and the second end plate 4 are combined to form Rectangular box structure.

[0066] The main body of the composite damper is arranged in a rectangular box, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com