MJS construction method main machine angle adjusting structure

A technology for adjusting the angle of the structure and the main engine, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., and can solve problems such as increasing construction costs and affecting construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

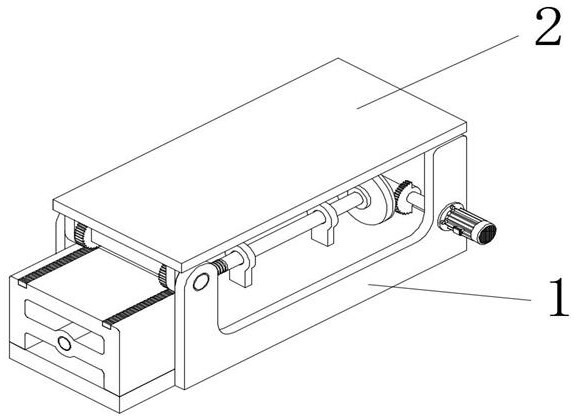

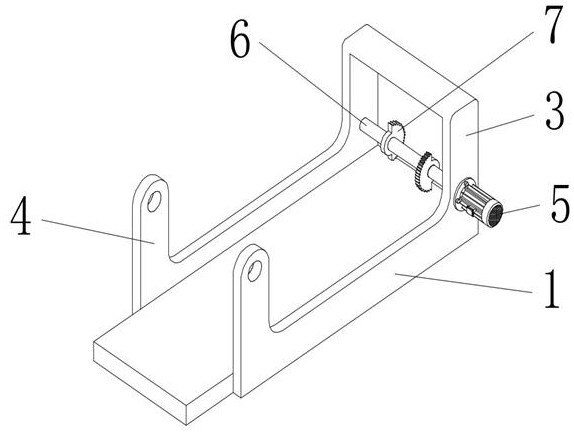

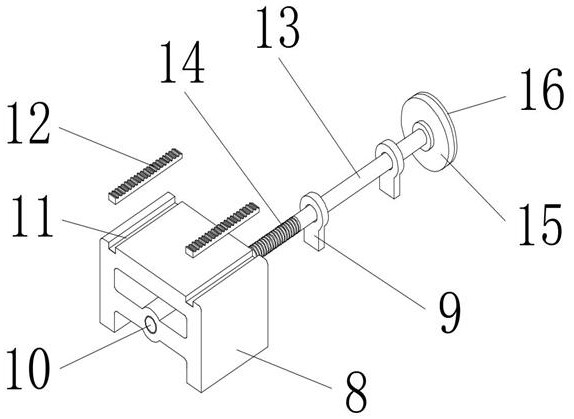

[0018] Such as Figure 1-4 As shown, an MJS construction method construction host angle adjustment structure includes a base 1 and a platform 2. The base 1 is provided with a rear support frame 3 and a front support frame 4. The rear support frame 3 is integrally connected to the top of the rear end of the base 1. The transmission motor 5 is installed and fixed on the lower left side of the support frame 3 through screws. The main shaft of the transmission motor 5 runs through and extends to the inside of the rear support frame 3. A transmission shaft 6 is installed and fixed through a coupling. The end of the transmission shaft 6 is connected to the rear support frame 3 through a bearing. The inner wall is interferingly connected, the middle section of the transmis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap