Test device and test method for mobile phone PCB board

A PCB board and testing device technology, applied in the field of circuit testing, can solve problems such as high probe unit price and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Because the probe is a consumable part, improving the probe will make the unit price of the probe higher and higher, and the cost of using the equipment will also increase. Soft landing is a problem that needs to be solved urgently. One of the solutions is to reduce the contact speed between the probe and the PCB board. However, reducing the moving speed of the probe will reduce the working frequency of the probe, thereby affecting the test efficiency.

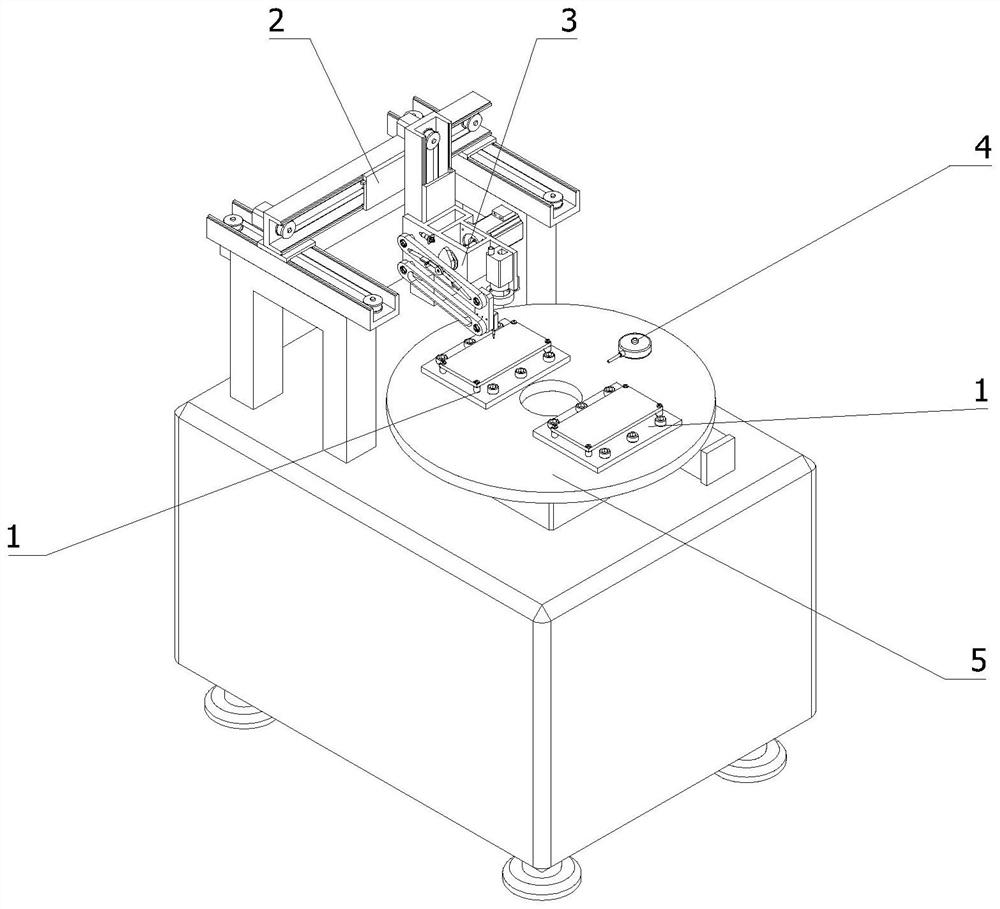

[0046] In order to solve this technical problem, such as Figure 1-3 shown, provide:

[0047] A test device for a mobile phone PCB board, comprising,

[0048] frame;

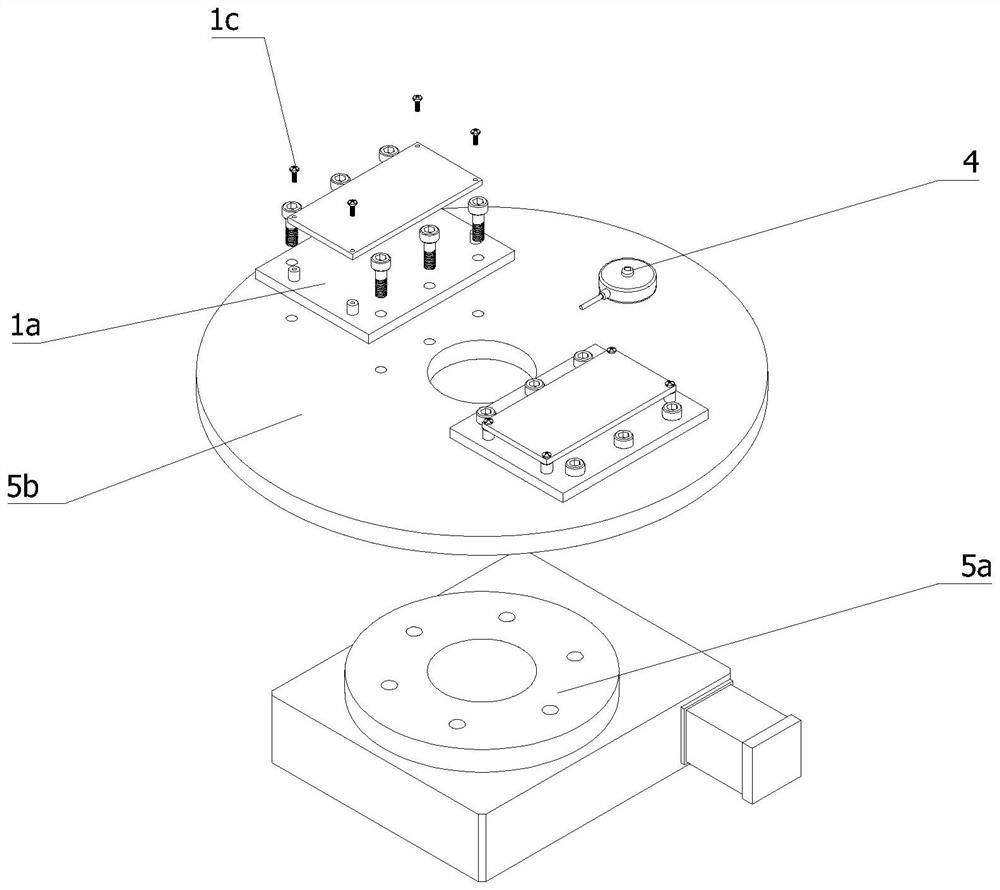

[0049] Fixture 1, which is set on the rack, and fixture 1 is used for positioning the PCB board;

[0050] Industrial robot 2, which is arranged on the rack;

[0051] The flying probe test shaft 3 is arranged at the output end of the industrial robot 2, and the flying probe test shaft 3 is used for circuit testing the PCB board;

[0052] Flying probe ...

Embodiment 2

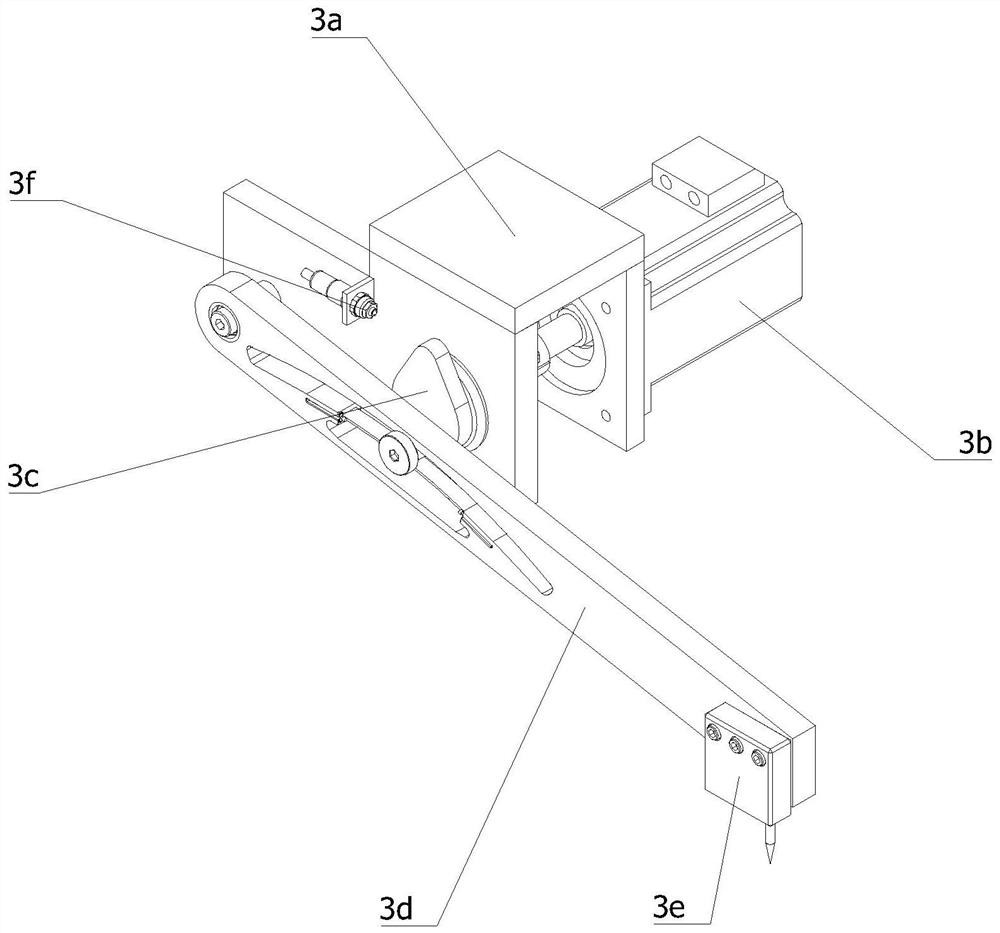

[0089] Since the movement trajectory of the free end of the first rocker arm 3d is an arc, it is difficult to calculate the angle of the detection end of the probe module 3e when the detection end of the probe module 3e is in contact with the PCB board. In order to solve this technical problem, such as Figure 8 and 9 As shown, the following preferred technical solutions are provided:

[0090] Flying probe test shaft 3 also includes,

[0091] The second rocker arm 3g, one end of which is mounted on the mounting frame 3a through a rotating pair, and the second rocker arm 3g is parallel to the first rocker arm 3d;

[0092] The two ends of the connecting rod 3h are respectively hinged with the free end of the first rocker arm 3d and the free end of the second rocker arm 3g, and the probe module 3e is installed on the connecting rod 3h.

[0093] Specifically, the mounting bracket 3a, the first rocker arm 3d, the second rocker arm 3g and the connecting rod 3h constitute a paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com