Return-to-zero judgment device and method used in galvanometer scanning rotation process

A galvanometer scanning and judging device technology, which is applied in the direction of using optical devices, measuring devices, and using re-radiation, can solve problems such as inability to meet high precision and high reliability, and interference of photoelectric couplers, so as to improve maintainability and overcome Working environment, the effect of ensuring zero precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

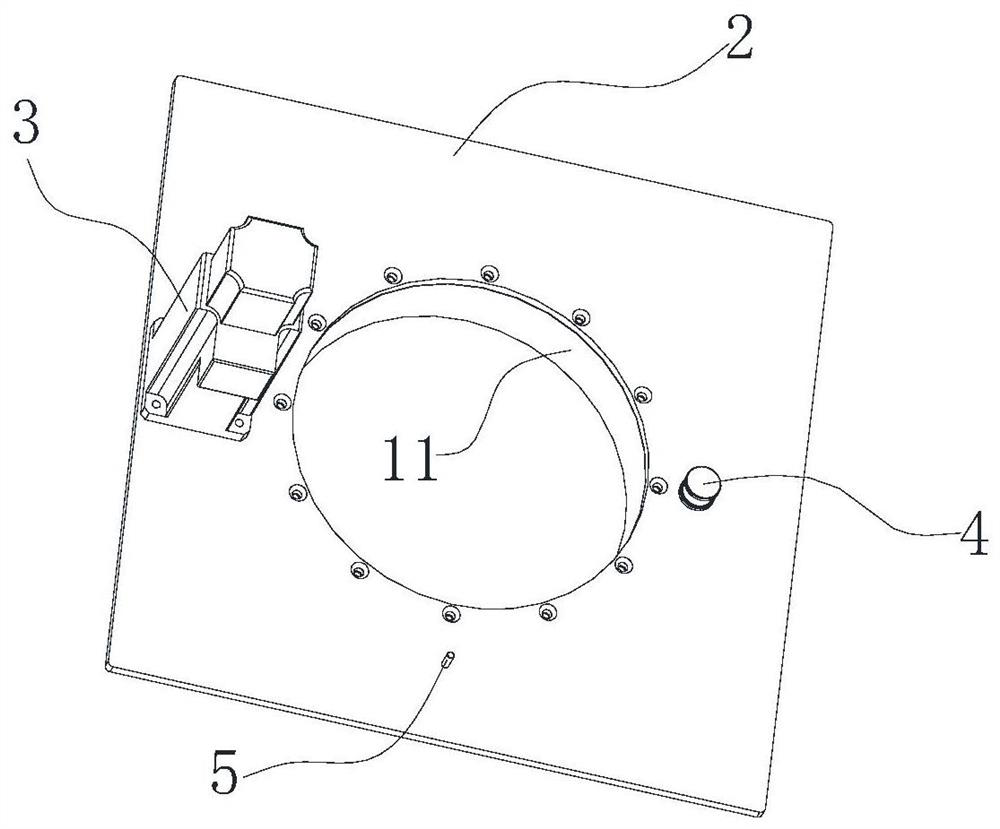

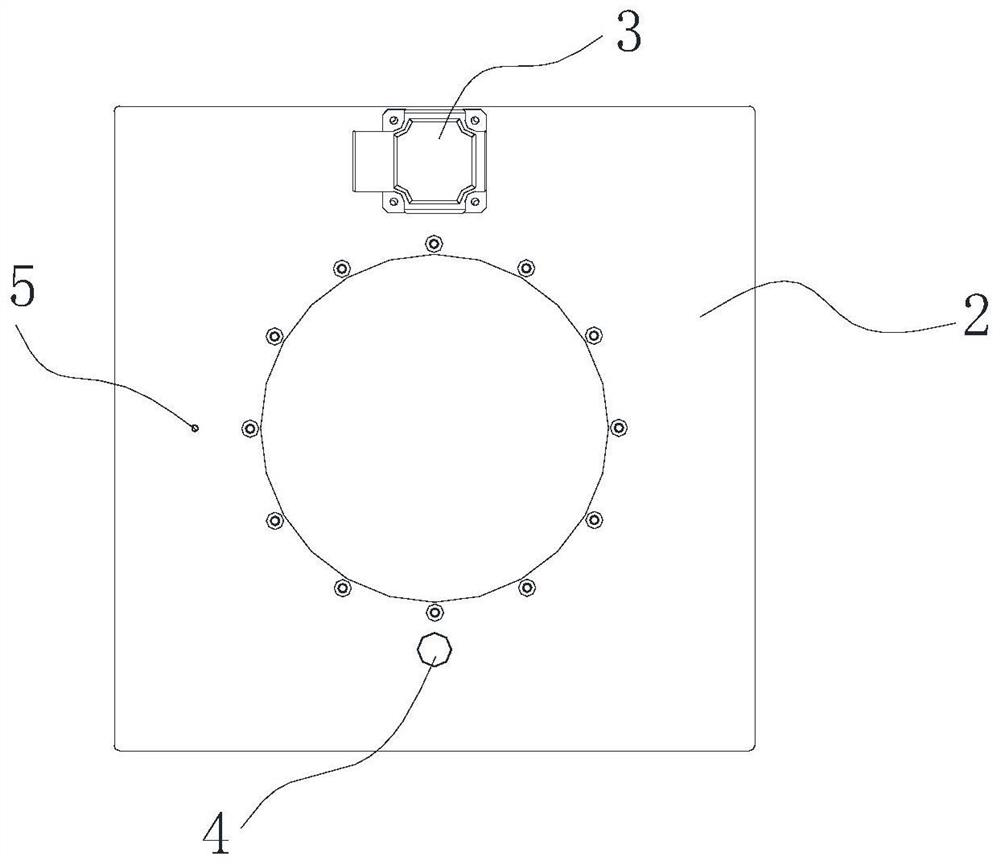

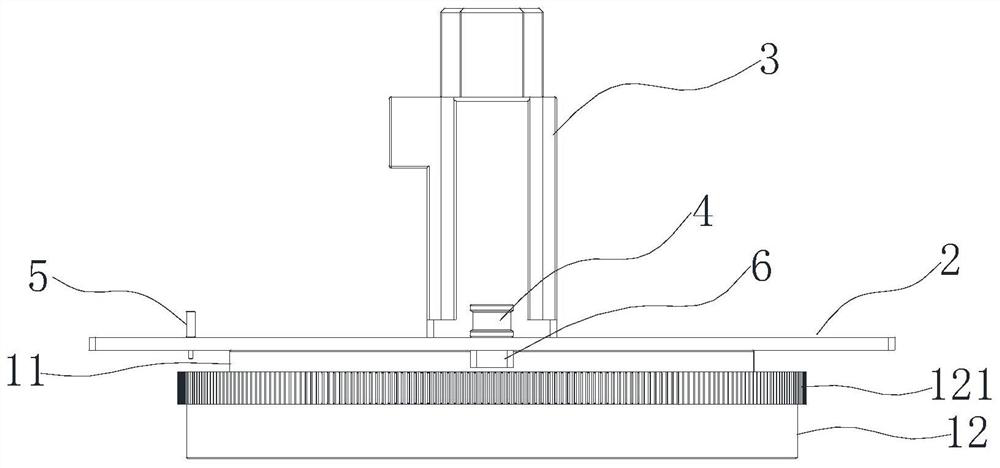

[0036] Such as Figure 1 to Figure 5 As shown, this embodiment discloses a device for judging zero return during the scanning and turning process of the vibrating mirror, including a slewing support 1, an installation support plate 2 is fixed on the inner ring 11 of the slewing support 1, and the installation support plate 2 is A driving device, an infrared sensor 4 and a laser sensor 5 are installed, the driving device is connected with the outer ring 12 of the slewing bearing 1, the outer ring 12 is equipped with a column A6, and the outer ring 12 is provided with a small hole B7 along the axial direction.

[0037] It should be noted that there are thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com