Device and method for calibrating zero positions of continuous casting-and-rolling high-speed flying shear rotating drum and equipment

A technology of continuous casting and rolling, zero calibration, applied in turning equipment, auxiliary equipment, metal processing equipment, etc., can solve the problems of continuous cutting of strip steel, stacking steel, and lying billet of casting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

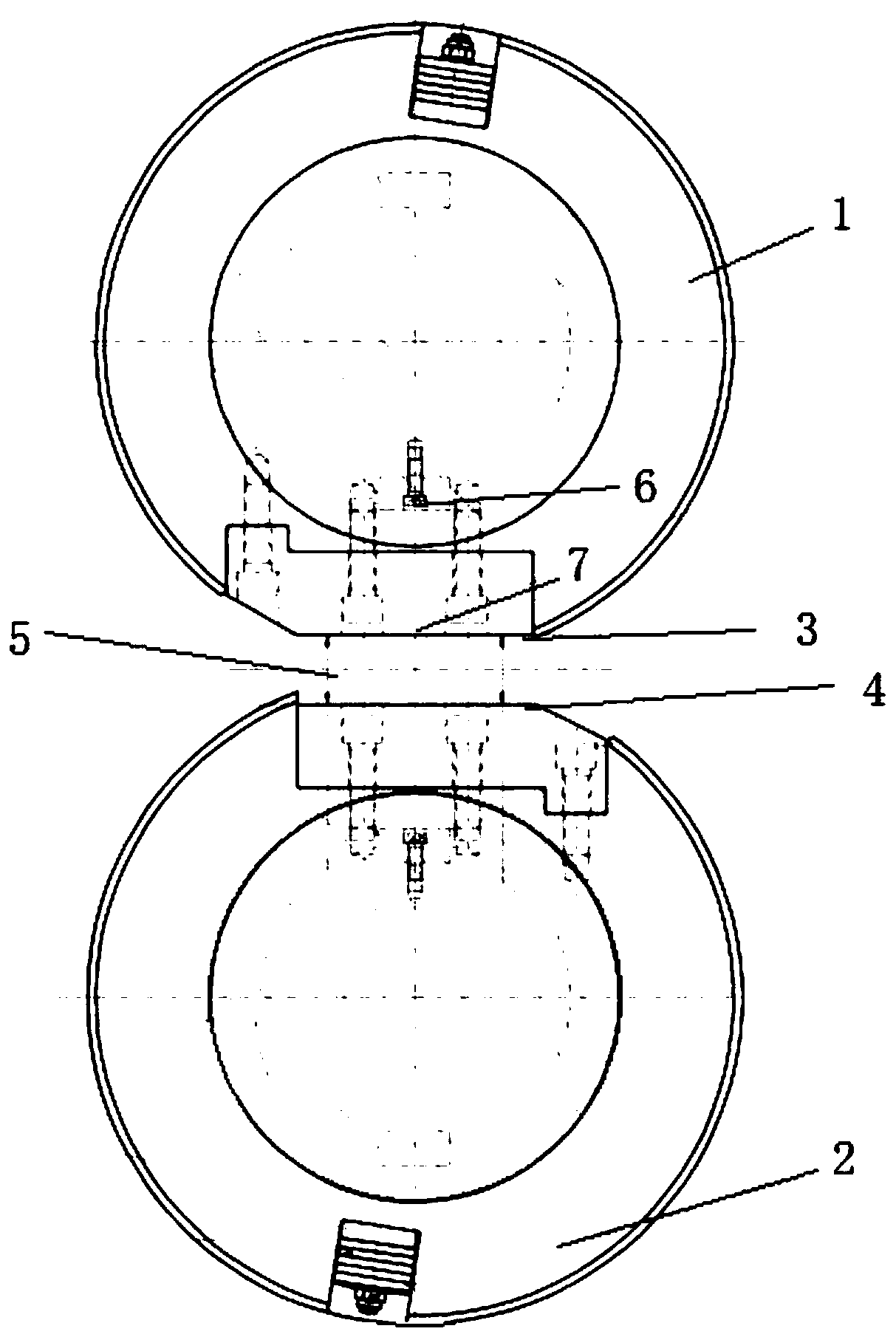

[0031] figure 1 It is a structural schematic diagram of a continuous casting and rolling high-speed flying shear drum zero calibration device in an embodiment of the present invention, as shown in figure 1As shown, a continuous casting and rolling high-speed flying shear drum zero calibration device, said device includes: a first drum 1, a second drum 2, a first horizontal plane 3, a second horizontal plane 4, and a calibration block.

[0032] The first drum 1 has a first zero position; the second drum 2 is arranged opposite to the first drum 1 and located below the first drum 1 , and the second drum 2 has a second zero position, said first zero position and said second zero position being on the same line.

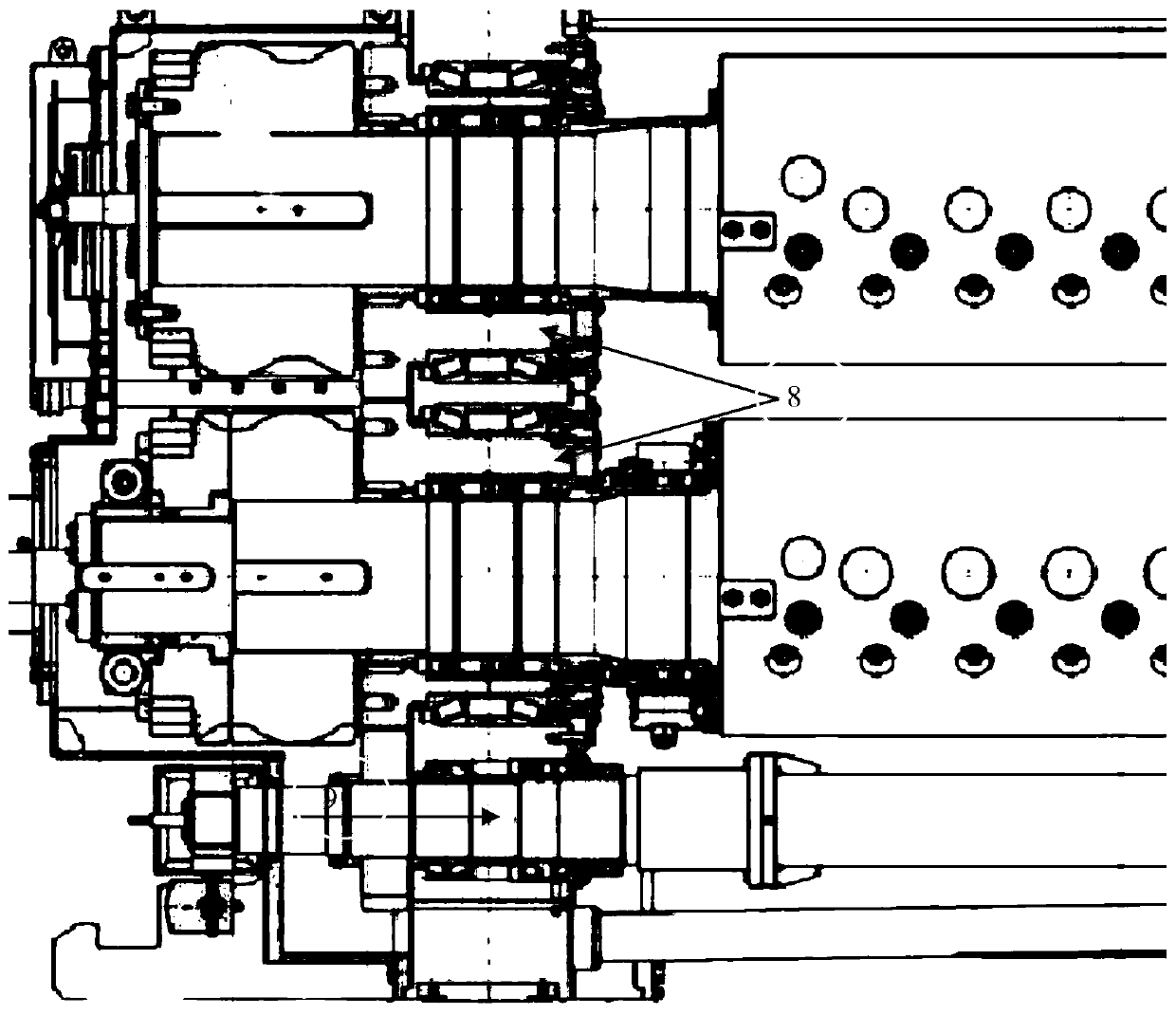

[0033] Further, the first drum 1 and the second drum 2 have the same structure, and both the first drum 1 and the second drum 2 include: a drum, an eccentric sleeve 8, a gear, and the drum has a rotating Drum zero position 6; the eccentric sleeve is arranged outside the...

Embodiment 2

[0047] A continuous casting and rolling high-speed flying shear equipment according to an embodiment of the present invention, including the continuous casting and rolling high-speed flying shear drum zero calibration device in the first embodiment, various variations and specific embodiments in the foregoing first embodiment A kind of continuous casting and rolling high-speed flying shear equipment that is also applicable to this embodiment, through the foregoing detailed description of a continuous casting and rolling high-speed flying shear drum zero calibration device, those skilled in the art can clearly know that this embodiment An implementation method of continuous casting and rolling high-speed flying shear equipment in the example.

Embodiment 3

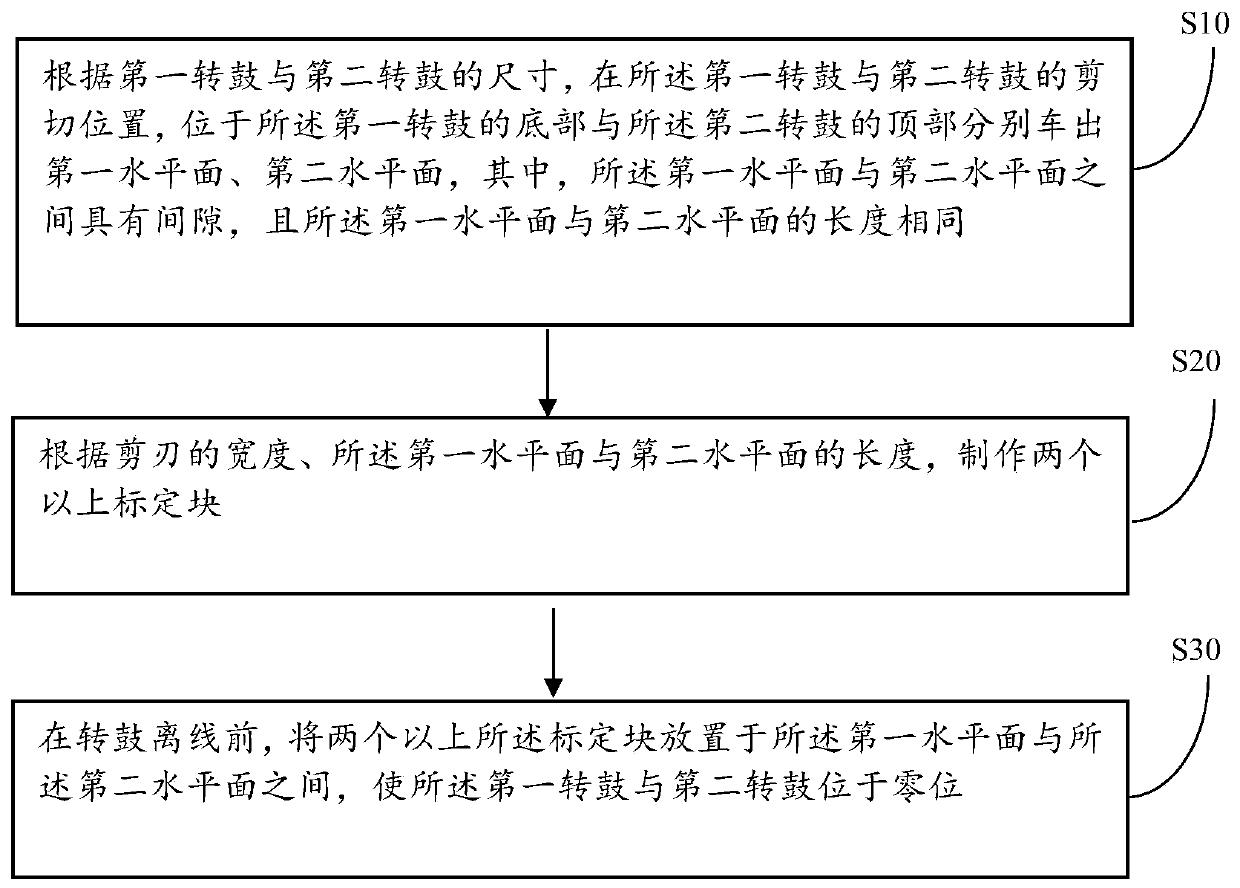

[0049] A method for calibrating the zero position of the high-speed flying shear drum for continuous casting and rolling in the embodiment of the present invention is applied to the zero position calibrating device for the high-speed flying shear drum for continuous casting and rolling in the first embodiment and the one in the second embodiment Continuous casting and rolling high-speed flying shear equipment, image 3 It is a schematic flow chart of a method for calibrating the zero position of a continuous casting and rolling high-speed flying shear drum according to an embodiment of the present invention, please refer to image 3 , the method includes:

[0050] Step 10: According to the size of the first drum 1 and the second drum 2, at the shearing position of the first drum 1 and the second drum 2, at the bottom of the first drum 1 and the second drum 2 The top of the drum 2 is driven out of the first horizontal plane 3 and the second horizontal plane 4 respectively, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com