Method for automatically generating stock ground belt flow control program

A process control and automatic generation technology, applied in the field of PLC control, can solve the problems of low efficiency and amazing workload, and achieve the effect of simple initialization and convenient modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A main process initialization ST statement is generated as follows:

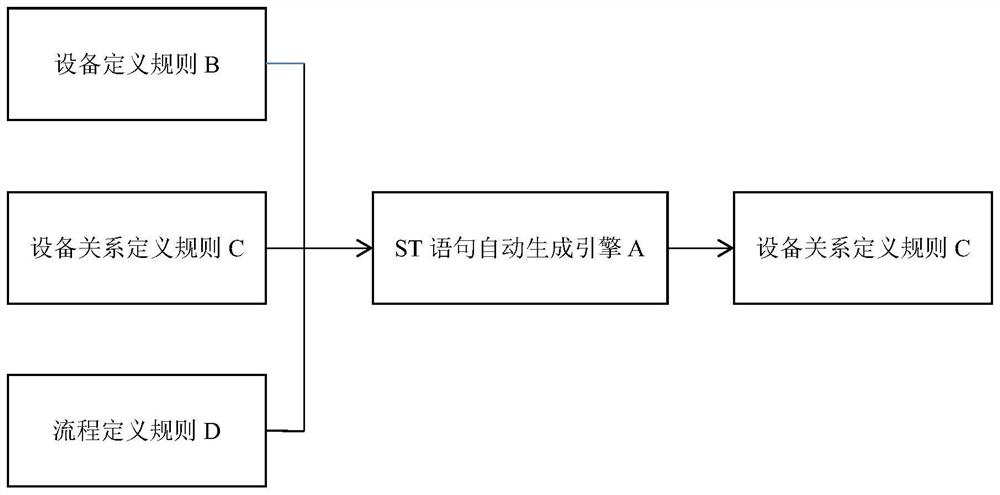

[0032] a) Write engine A, engine A needs to be written according to the generated ST statement. After the writing is completed, it can be recycled many times. The implementation method of engine A adopts java language, but it is not limited to this.

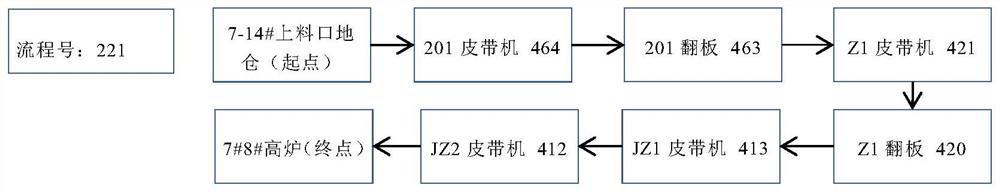

[0033] b) Process initialization The default definition in the PLC is as follows: "MX_Flow".Flow[221].FLOW[464]:=1; the numbers in the square number are automatically generated according to the rules, and other characters are fixed by default. Every initialization statement is the same. The meaning of process initialization is to traverse all processes and devices in each process, and assign a value of 1 to each device in each process number.

[0034] c) Then engine A reads the process definition rule D, removes the starting point and the end point, and reads each device. Since the device and the device number are separated by a space, it is easy to r...

Embodiment 2

[0037] A main flap initialization ST statement is generated as shown below

[0038] a) Write engine A, engine A needs to be written according to the generated ST statement. After the writing is completed, it can be recycled many times. The implementation method of engine A adopts java language, but it is not limited to this.

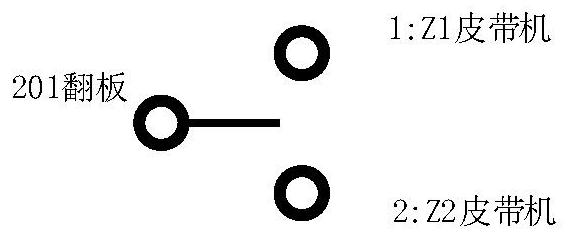

[0039] b) Read the equipment relationship definition rule C, and obtain that the 201 flap has two corresponding belt conveyor relationships, Z1 belt conveyor and Z2 belt conveyor.

[0040] c) Read the equipment definition rule B to obtain the respective equipment serial numbers of the 201 flap, the Z1 belt conveyor, and the Z2 belt conveyor

[0041] d) and define the variable and immutable parts in the ST text. Among them, the ones in the square brackets below are variable, and the others are immutable parts.

[0042] MX_Mar_K.Device_Infeed[421]:=(MX_POS_K.Device_Pos[463]=1) AND MX_Mar_K.Device_Outfeed[463];

[0043] MX_Mar_K.Device_Infeed[460]:=(MX...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com