Permanent magnet type stepping motor subdivision driving method

A stepping motor and subdivision drive technology, which is applied in the direction of motor generator control, electrical components, control systems, etc., can solve the problems of increasing system performance requirements and limitations, and achieve the effect of reducing torque disturbance and lowering performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

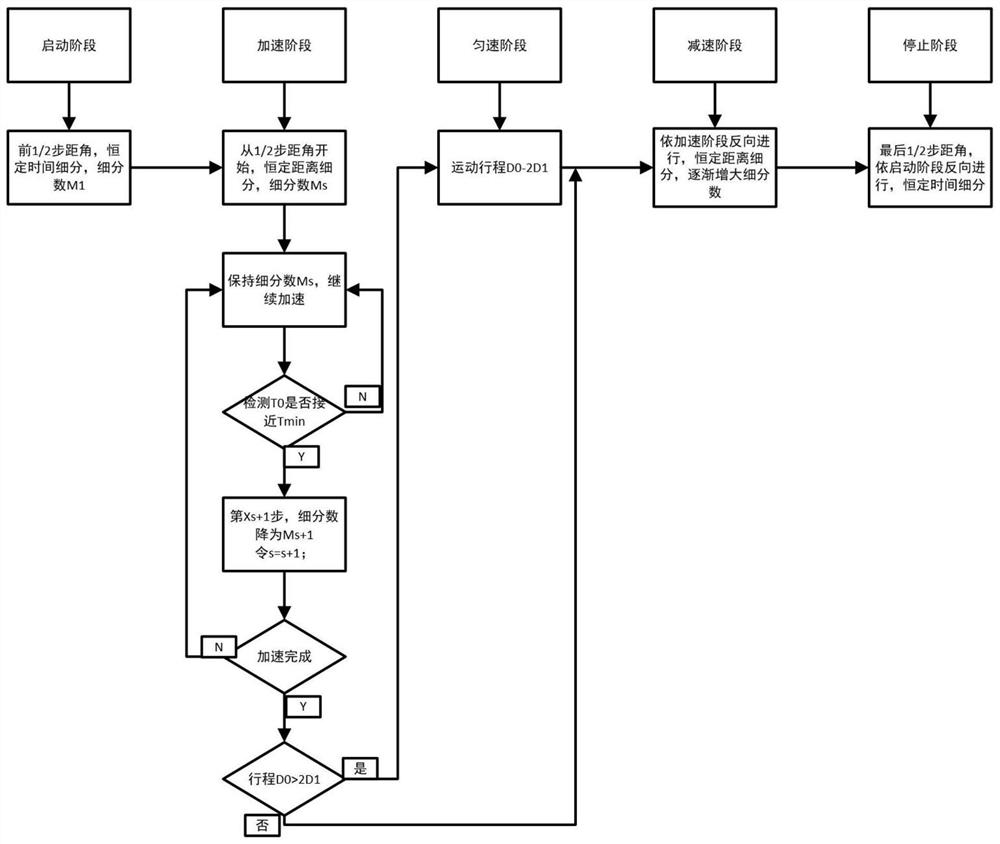

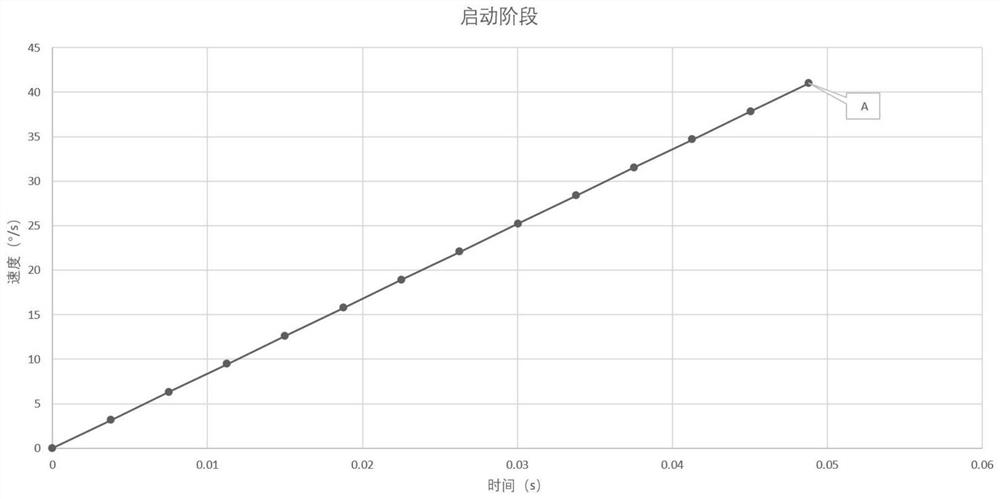

[0028] In this example, a permanent magnet type stepper motor drive method is applied in the drive system of the permanent magnet type stepper motor, and includes the following steps:

[0029] Step 1. Set the maximum speed Vmax and acceleration a of the stepping motor, and meet the requirements: Accelerate the stepping motor with the acceleration a, and the motor speed achieved when the total stroke runs 1 / 2 is greater than the set maximum speed of the stepping motor Vmax;

[0030] In actual engineering, the motion angle of the load is arbitrary, no matter how the stepping motor moves, the driving algorithm should work. The top speed of a stepper motor is less than what can be achieved in 1 / 2 of the total travel angle. Then if the motion is long enough, the stepper motor must stop accelerating and run at top speed until it needs to slow down.

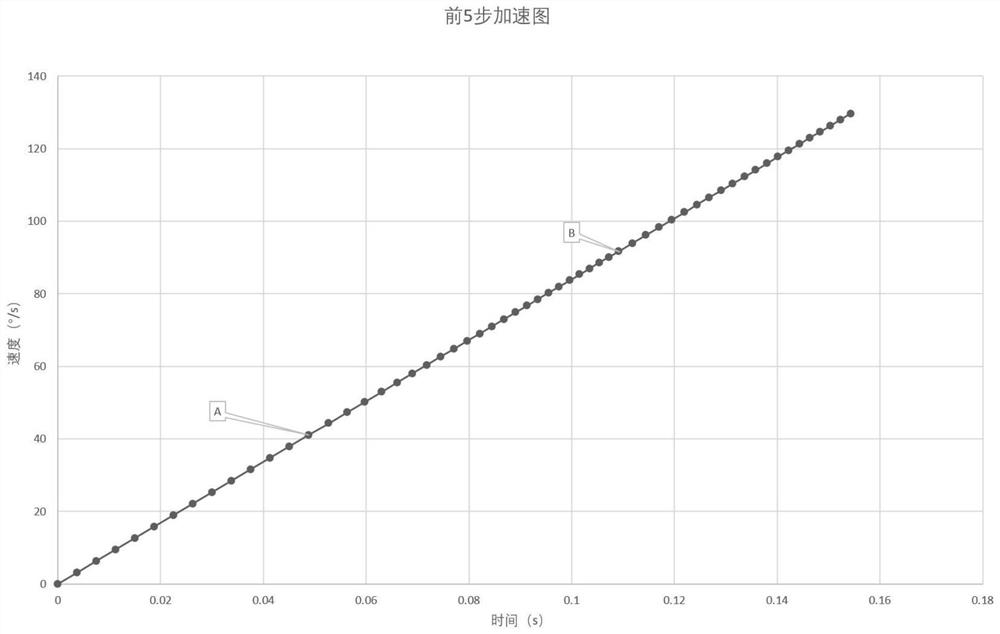

[0031] Let the natural frequency of the driving system be Fmin, the interrupt service frequency of the processor in the driving syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com