Trolley with air injection auxiliary power mechanism and control method thereof

A technology of auxiliary power and power mechanism, which is applied in the direction of motor vehicles, power devices, vehicle parts, etc., and can solve problems such as difficulty in improving maneuverability, difficulty in ensuring chassis stability, and low grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

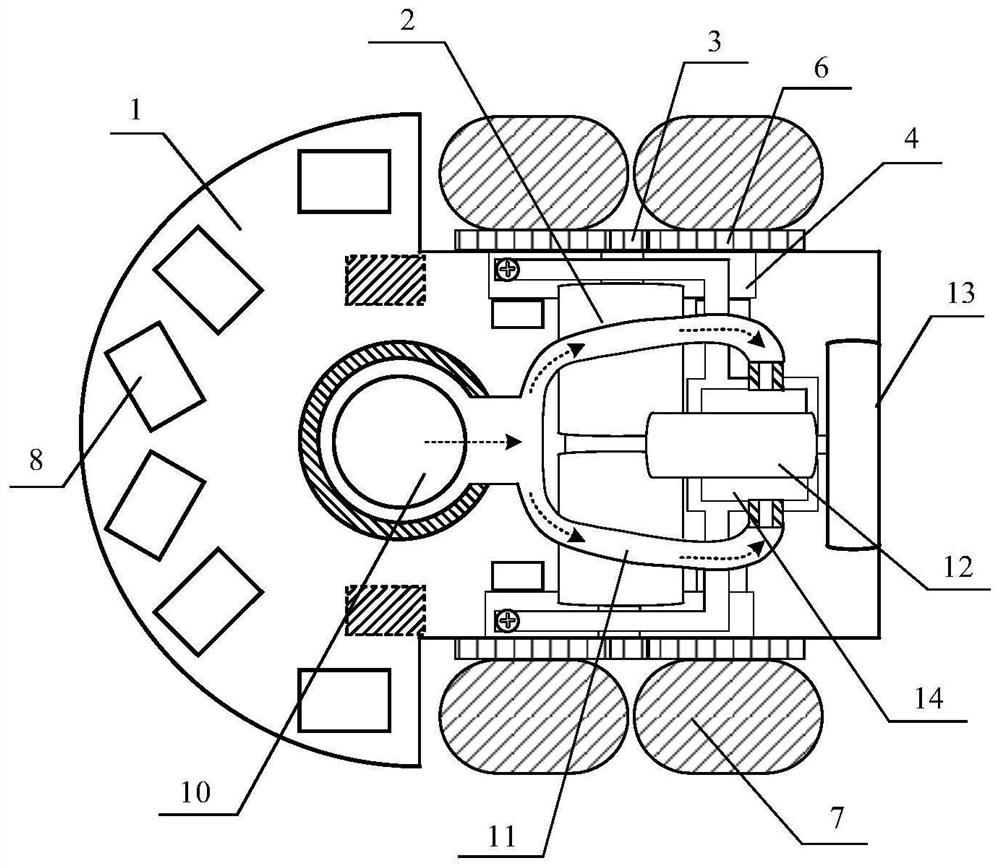

[0028] like figure 1 Shown is a top view of a robot car equipped with an air jet auxiliary power mechanism, which is composed of four parts: a control circuit board 1, a drive mechanism, a vision mechanism and an auxiliary power mechanism. The control circuit board 1 also serves as the chassis of the robot, and is provided with through holes. The power mechanism includes main motor 2, transmission gear 3, wheel hub bracket 4, metal bearing 5, wheel hub 6 and tire cover 7. There are two main motors 2 and are located above the control circuit board, transmission gear 3, wheel hub bracket 4, wheel hub 6 and Tire cover 7 is positioned at control circuit board both sides. The visual mechanism includes six groups of digital infrared sensors 8 that are independently arranged and do not interfere with each other, and are installed on the front side of the control circuit board. Among them, each group of digital infrared sensors includes an infrared emitting tube and an infrared rece...

Embodiment 2

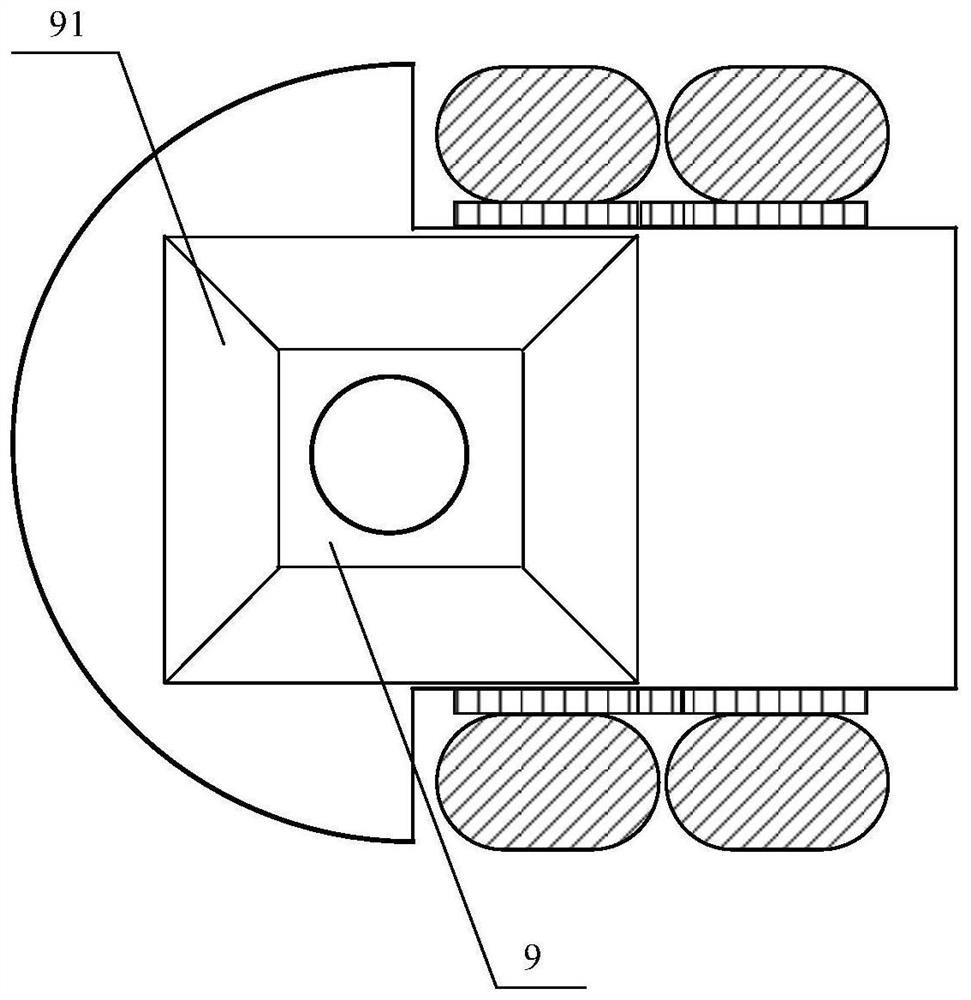

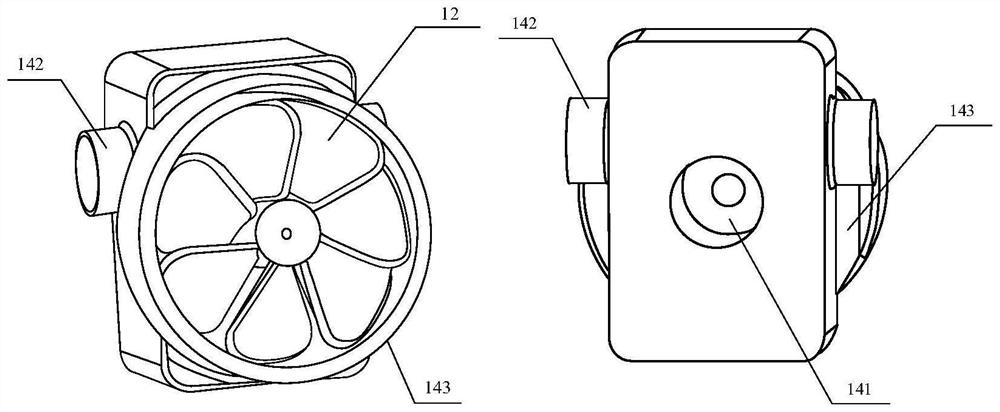

[0040] like Figure 4 Shown is a top view of a robot car equipped with an air jet auxiliary power mechanism, which is composed of four parts: a control circuit board 1, a drive mechanism, a vision mechanism and an auxiliary power mechanism. Among them, the driving mechanism and visual mechanism are exactly the same as Case 1. The control circuit board 1 also serves as the chassis of the robot, and is provided with two through holes on the left and the right. The auxiliary power mechanism includes a semi-closed cavity 9 under the plate, an air suction cavity 10 on the plate, an air delivery pipe 11, a fan motor 12, a pneumatic fan blade 13 and an air injection cavity 14. There are two air injection chambers 14, each equipped with a fan motor 12 and a pneumatic fan blade 13 separately. The air pumping chamber 10 on the board has two chambers in total, and the air conveying pipe 11 has two paths in total, including a left conveying pipe and a right conveying pipe. A jet chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com