Superstructure assembly and installation method thereof

A technology of superstructure and installation method, applied in superstructure, ship parts, ship construction and other directions, can solve the problems of wasting welding resources, increasing hoisting weight, labor and time consuming, etc., and achieve the effect of saving welding materials and reducing hoisting weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

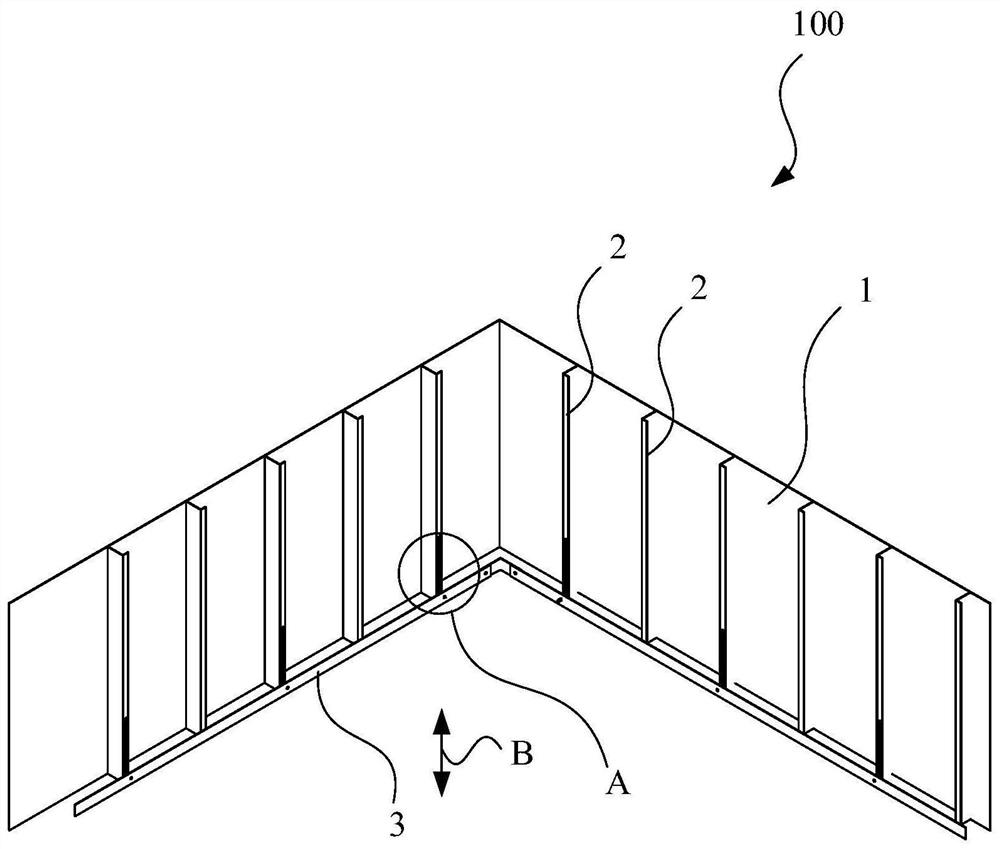

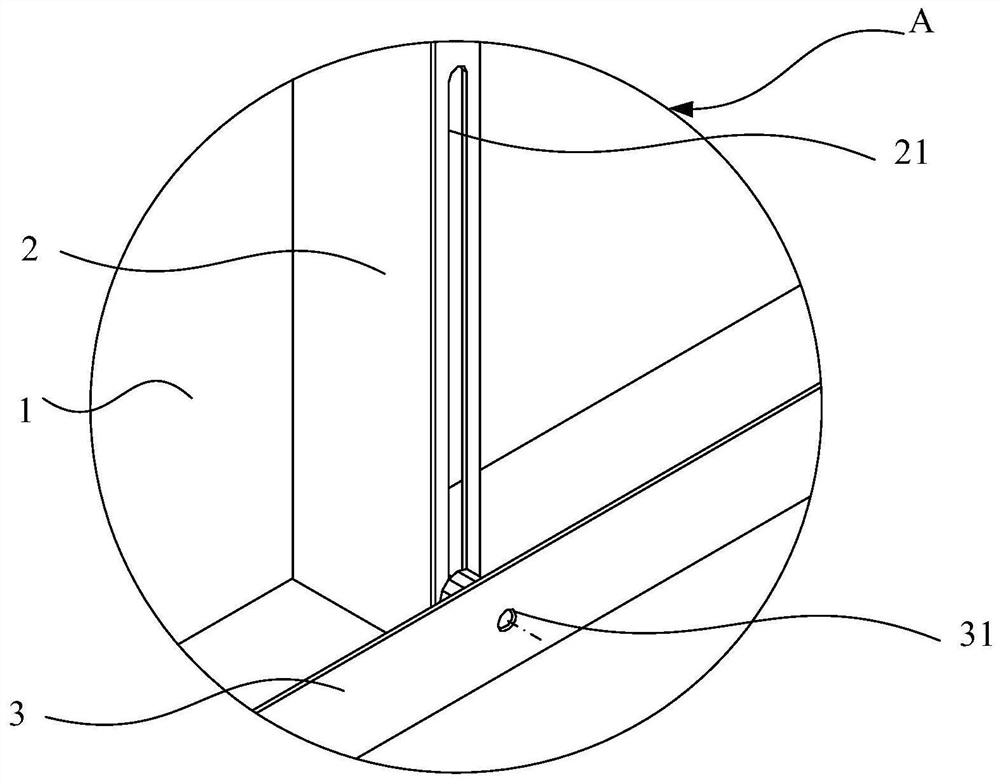

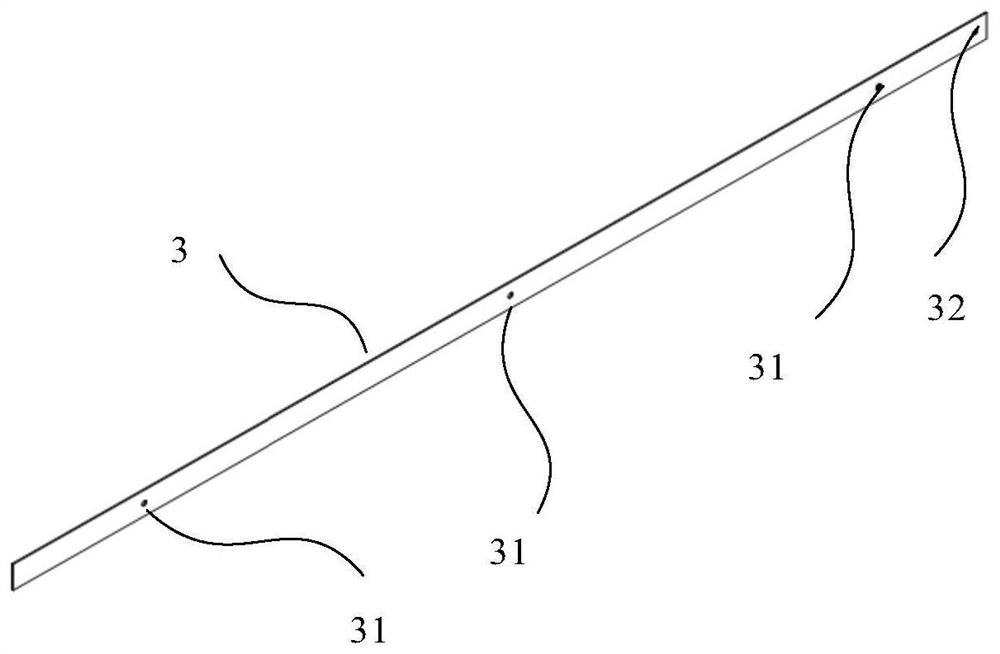

[0056] like figure 1 As shown, the present invention provides a superstructure component, which includes a steel enclosure wall 1 and several reinforcing members 2 welded on the surface of the steel enclosure wall 1 for strengthening the structural strength of the steel enclosure wall 1 . In this embodiment, the number of superstructure components is two, and the two are arranged opposite to each other at 90°. The superstructure assembly in this embodiment also includes a leveling iron 3 connected to the reinforcing material 2, wherein the leveling iron 3 needs to be connected to at least two reinforcing materials 2 at the same time to achieve the purpose of auxiliary reinforcement, Moreover, the position of the horizontal iron 3 along the vertical direction B relative to the steel surrounding wall 1 can be adjusted.

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com