Superconducting cable vertical winding device based on strip-shaped material

A technology of superconducting cables and winding devices, which is applied in superconducting devices, superconducting/high-conducting conductors, and the usage of superconducting elements. Inconsistency and other problems can be achieved to improve winding production efficiency, reduce conveying resistance, and avoid cable-stayed twisting and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

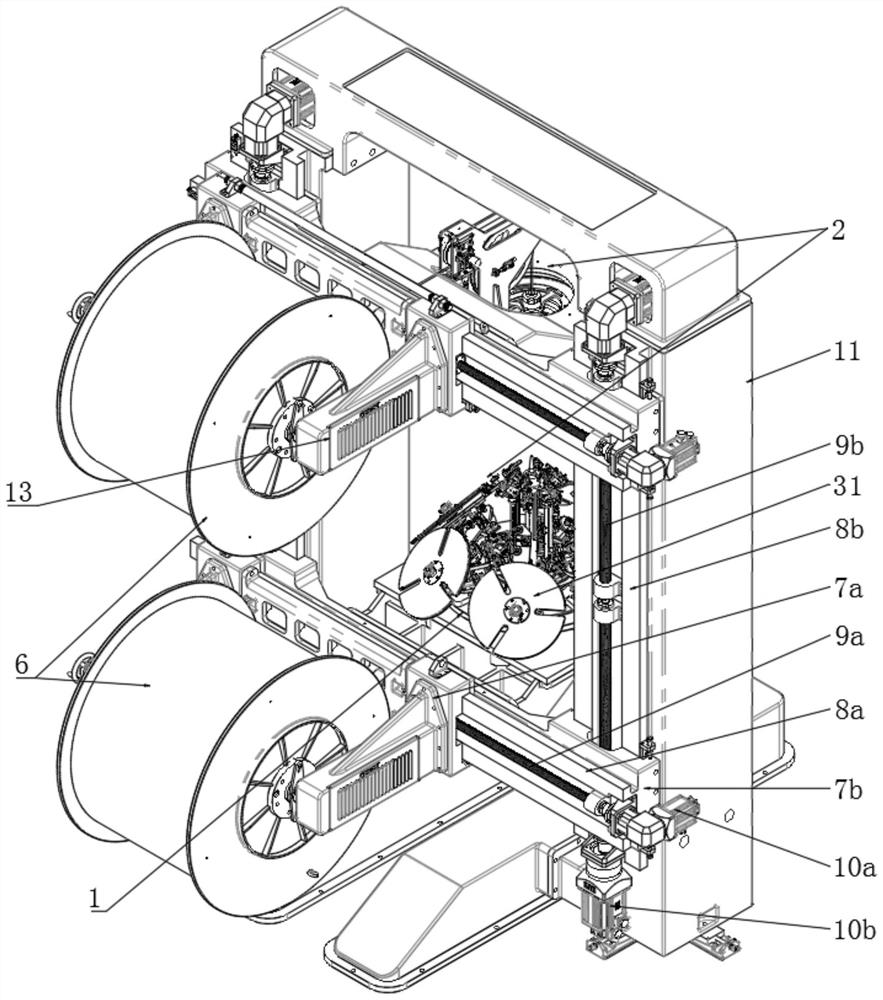

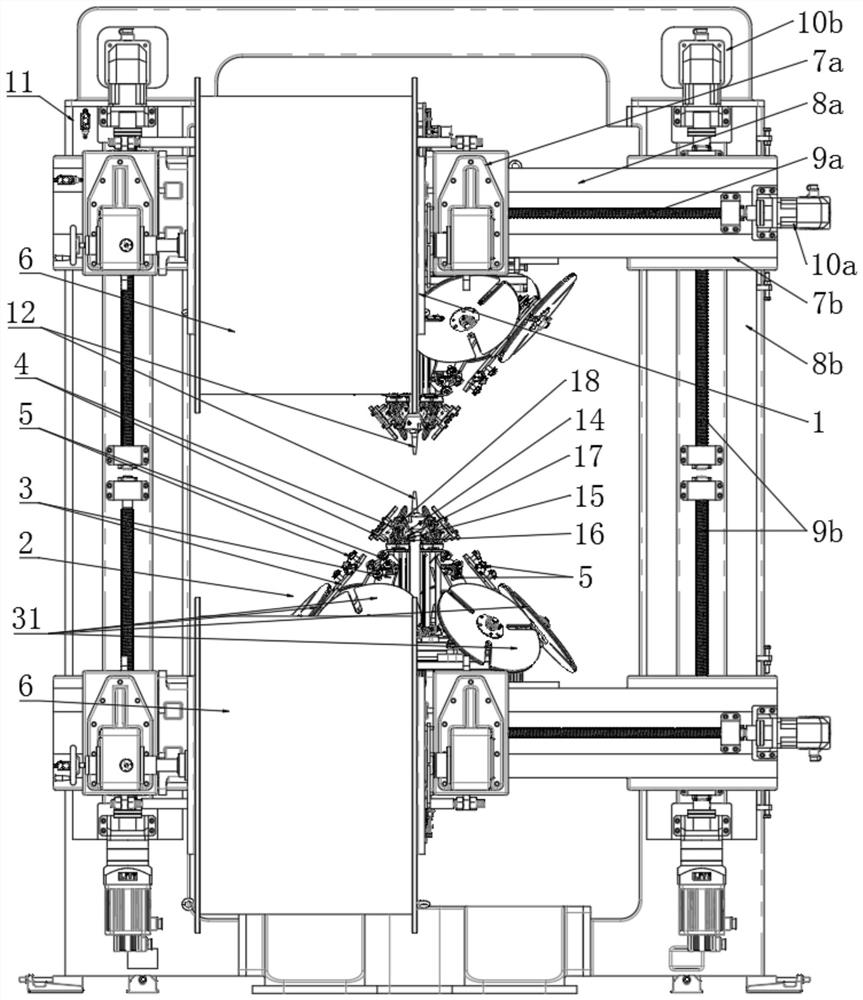

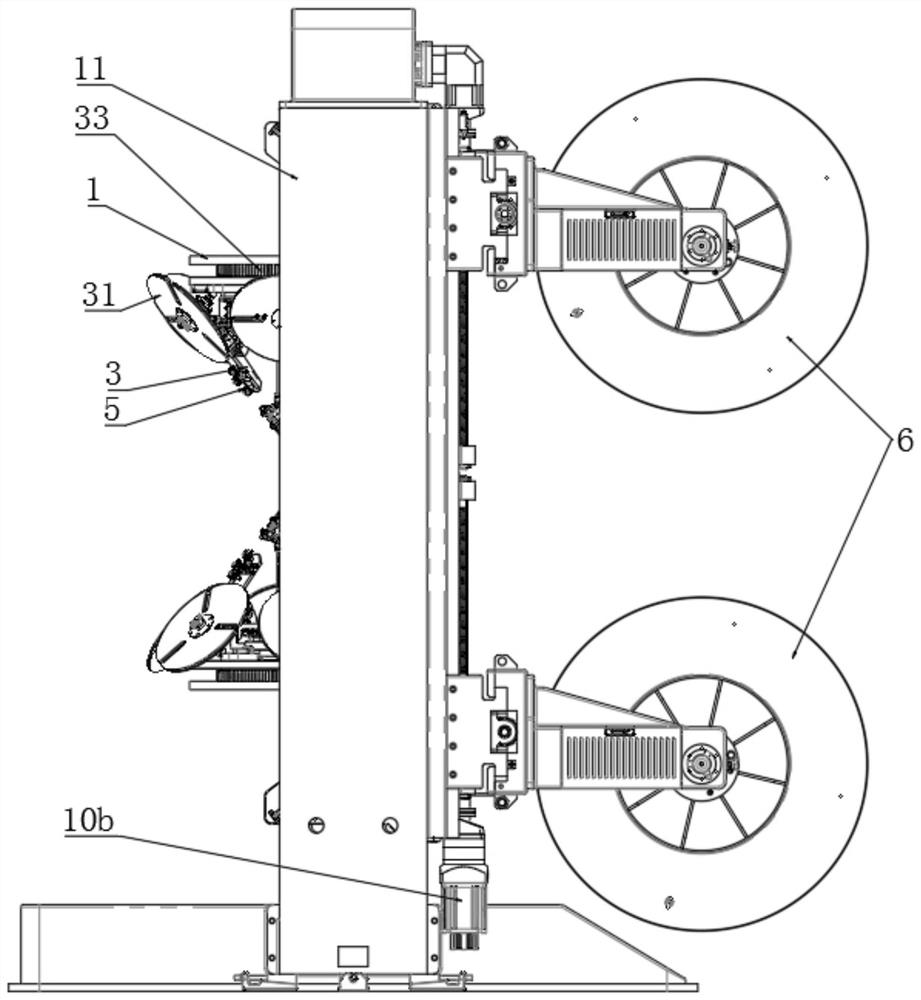

[0017] In order to facilitate a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings.

[0018] Such as Figure 1-5 shown. That Figure 4 Only one feed winder is shown in the guide and reel. The superconducting tape winding method of the present invention is: the conductor is passed through the input device and the output device that are vertically arranged, that is, vertically or vertically, and the vertically arranged, that is, vertically or vertically transported and operated, and the winding device is arranged in a corresponding horizontal direction. Or the horizontal plane mode, at the same time, the driver is installed at the input and output ends of the conductor or the input and output device at the same time, and the two drivers implement synchronous operation through its synchronizer, so that the conductor does not shake when the superconducting tape is wound, and the stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com