Nitrogen-doped rhodium carbon catalyst as well as preparation method and application thereof

A nitrogen doping and catalyst technology is applied in the field of nitrogen doping rhodium carbon catalyst and its preparation, which can solve the problem of unsuitability for the hydrogenation reaction of binaphthol, and achieve high reaction activity and regioselectivity, simple post-processing and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The invention provides a kind of preparation method of nitrogen-doped rhodium carbon catalyst, comprises the steps:

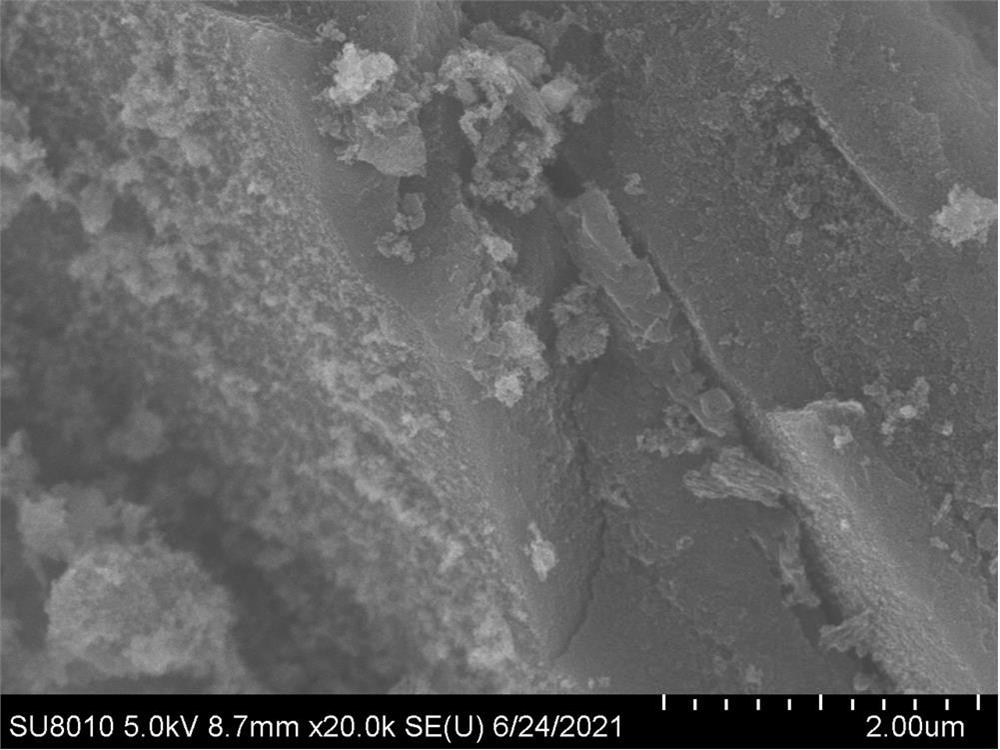

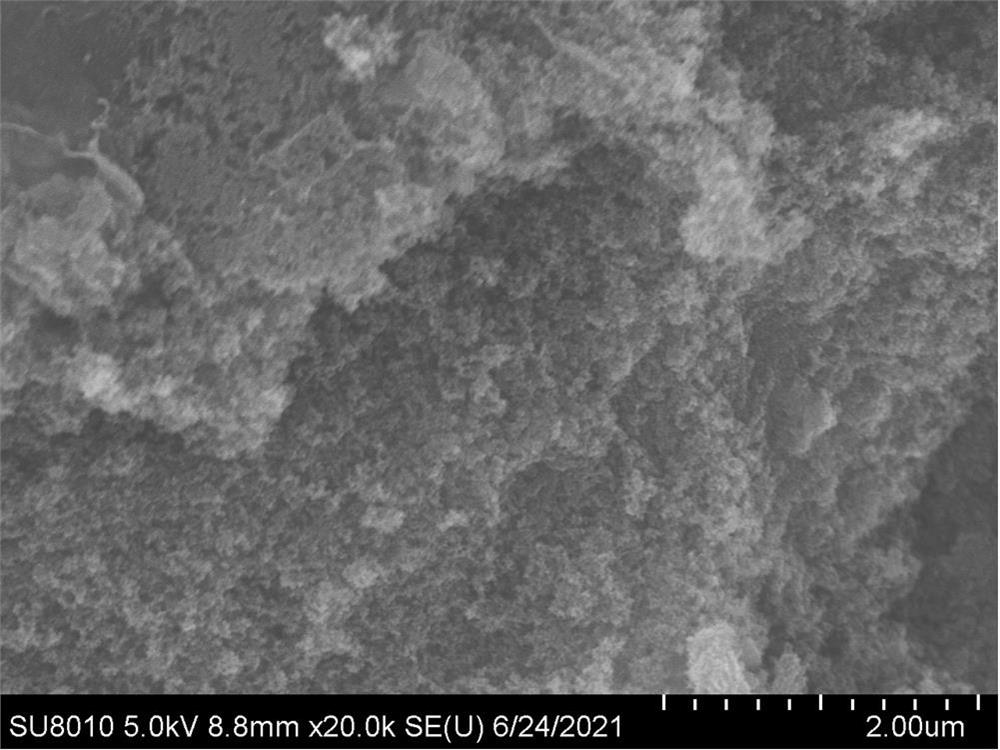

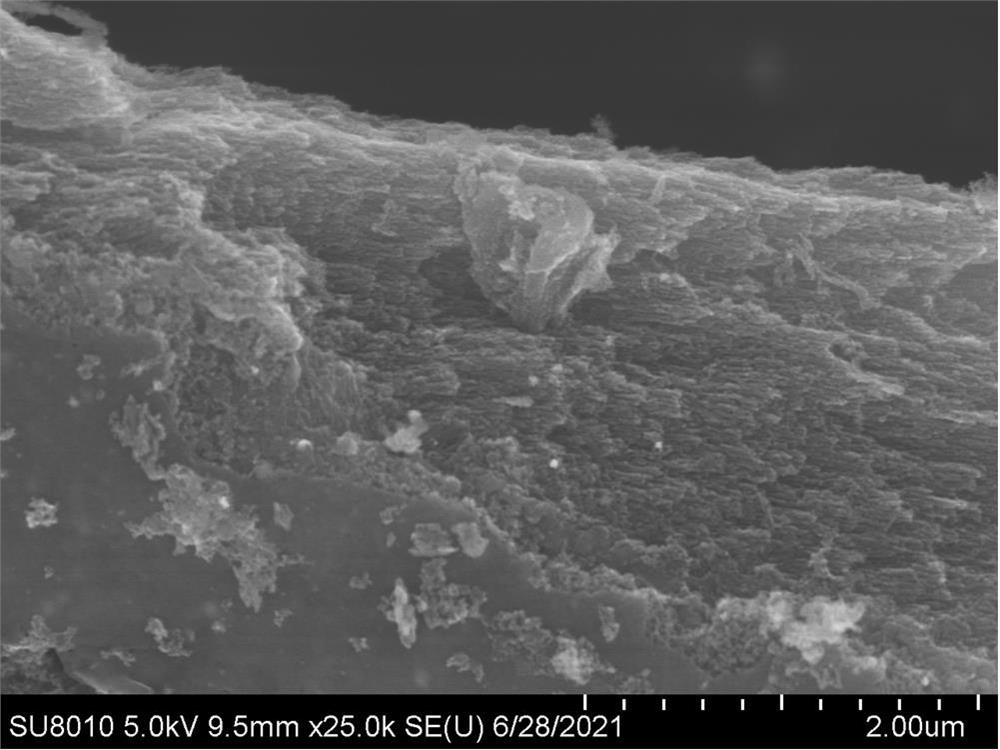

[0060] Mix activated carbon, nitrogen-containing compound and the first solvent for reflux reaction to prepare nitrogen-doped activated carbon; in nitrogen-doped activated carbon, the N atoms in the nitrogen-containing compound are connected to the C atoms in the activated carbon in the form of chemical nitrogen;

[0061] mixing nitrogen-doped activated carbon, rhodium salt and a second solvent for impregnation treatment to prepare a catalyst precursor;

[0062] The catalyst precursor is subjected to reduction reaction and alkali treatment to prepare nitrogen-doped rhodium carbon catalyst.

[0063] In some of these examples, the rhodium salt is selected from at least A sort of.

[0064] In some examples, the nitrogen-containing compound is selected from diethylenetriamine (DETA), ethylenediamine (EDA), N,N,N',N'-tetramethylethylenediamine (TMEDA), N,N ...

Embodiment 1

[0097]Present embodiment is a kind of preparation method of nitrogen-doped rhodium carbon catalyst, and the steps are as follows:

[0098] (1) Symmetrically take 61.80g of activated carbon (with a water content of 23.14%) for acid oxidation treatment, that is, add activated carbon to HNO with a mass concentration of 5% 3 In the aqueous solution, reflux and boil for 2 hours, after cooling, filter and wash until neutral, then drain to obtain activated carbon after acid oxidation treatment.

[0099] (2) Mix diethylenetriamine (DETA) ethanol aqueous solution (20 / 30 / 50=V / V / V) with the activated carbon after acid oxidation treatment in step (1) and reflux for 2 hours, filter, wash and dry, and place in Dry overnight in a 353K oven to obtain pretreated activated carbon.

[0100] (3) Disperse the activated carbon pretreated in (2) into 500mL of vigorously stirred pure water to obtain suspension A of pretreated activated carbon.

[0101] (4) 6.4395g (24.239mmol) of RhCl 3 •3H 2 O w...

Embodiment 2

[0118] The catalysts of Examples and Comparative Examples were respectively applied to the synthesis of chiral octahydrobinaphthol (R-H8-BINOL), the steps are as follows: R-BINOL R-H8-BINOL(R)-(+)-1,1'-binaphthyl-2,2'-diphenol(R)-(+)-5,5',6,6',7 ,7',8,8'-Octahydro-1,1'-2-naphthol

[0119] Add 50g (174.63mmol) R-BINOL, 800mL isopropanol and 0.7189g (0.349mmol by dry weight) catalyst into a 1L stainless steel autoclave, adjust the hydrogen pressure to 1.0MPa, and stir at 600rpm, 313K After reacting for 2 hours under the same conditions, samples were taken for analysis, and the conversion rate was detected by HPLC. The samples were filtered and spin-dried to obtain chiral octahydrobinaphthol (R-H8-BINOL) solids, which were sent for determination of ee value.

[0120] Further, the catalyst after the completion of the reaction is used as an experiment, the steps are as follows:

[0121] Filter the reaction system after catalytically synthesizing chiral octahydrobinaphthol to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com