Efficient automatic detection gluing mechanism for functional decorative paper processing

An automatic detection and decorative paper technology, applied in the cleaning method using tools, the cleaning method using gas flow, coating, etc., can solve the defects, protrusions, and easy adhesion of decorative paper on the adhesive surface of decorative paper Impurities and other problems can be improved to improve quality and reduce defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

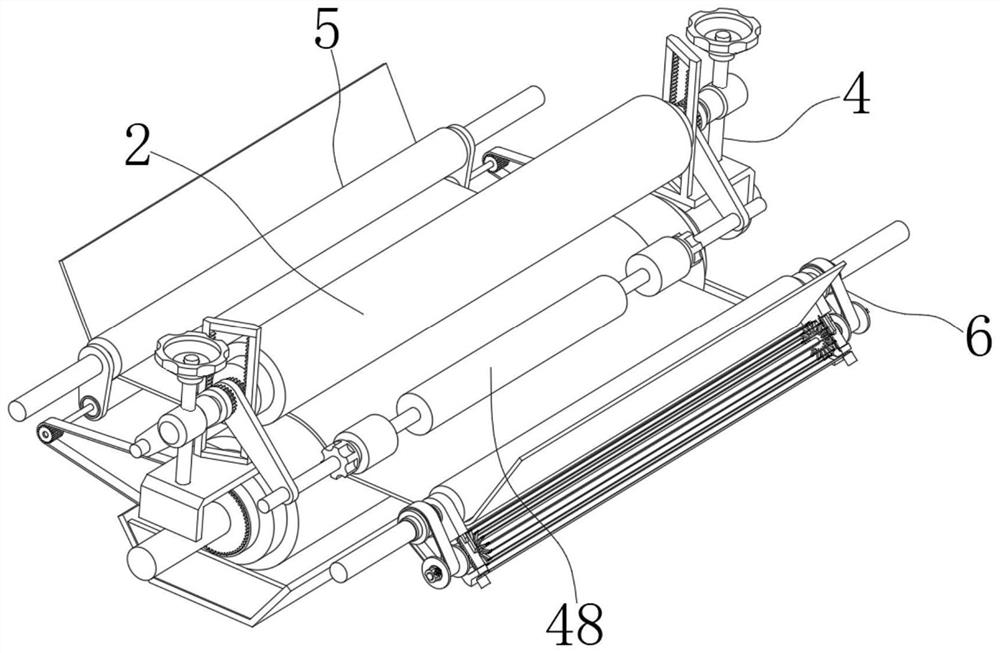

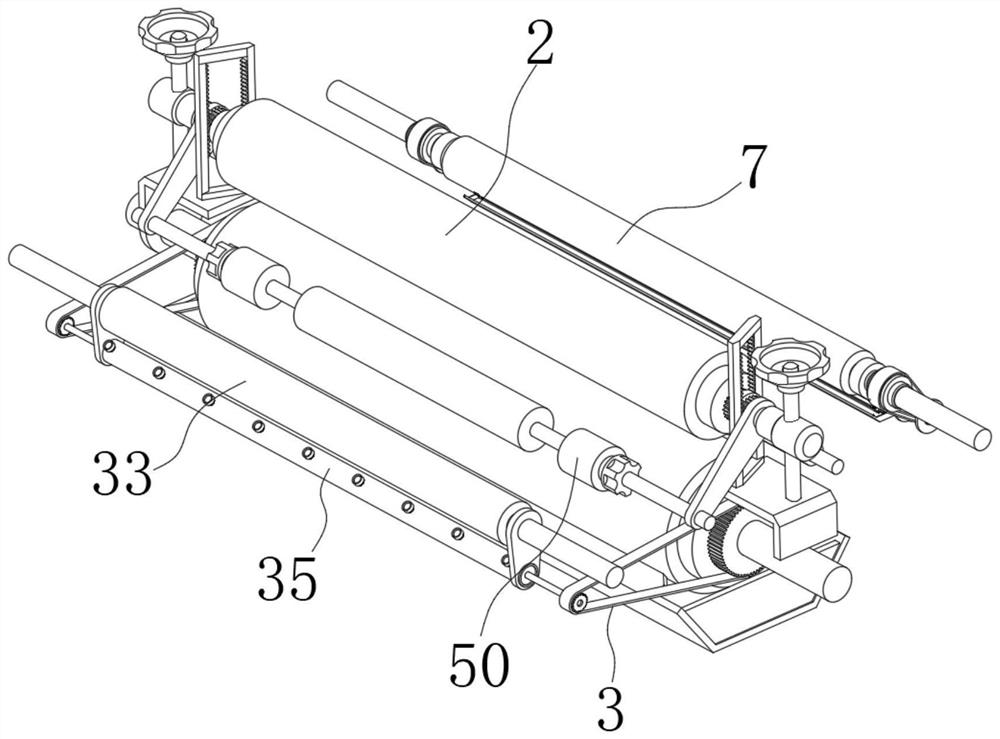

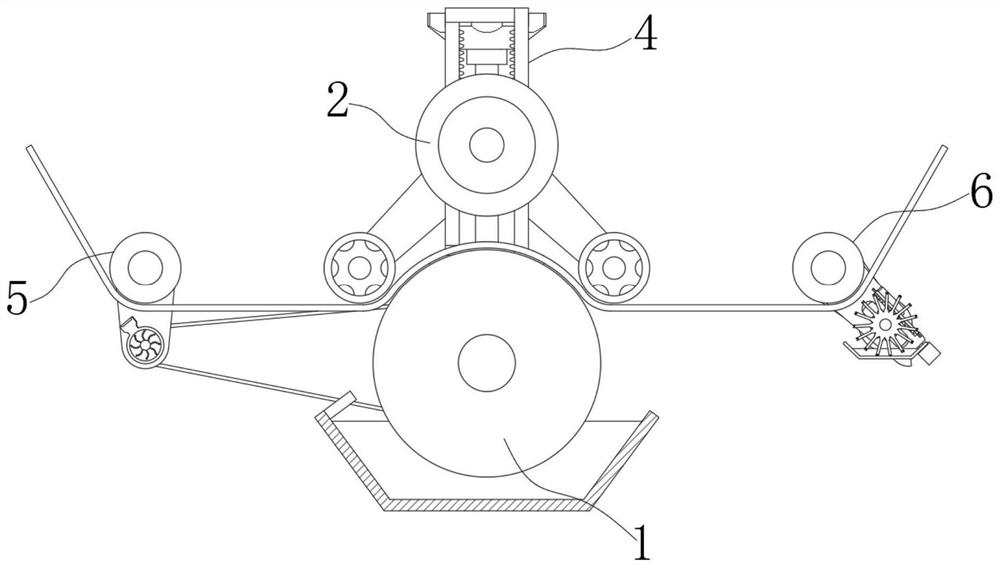

[0031] see Figure 1-Figure 9 , Figure 11 and Figure 12 , a high-efficiency automatic detection gluing mechanism for functional decorative paper processing in the illustration, including a gluing roller 1, a pressure roller 2, a pretreatment mechanism 5 and a miscellaneous removal mechanism 6, and the gluing roller 1 rotates Installed on the inner wall of the gluing machine, and the two ends of the gluing roller 1 are provided with a driving member 3, and the two ends of the pressure roller 2 are equipped with a connecting assembly 4, and are installed on the inner wall of the gluing machine through the connecting assembly 4, for The pretreatment mechanism 5 for removing impurities on the glued surface of the decorative paper is installed at the paper inlet of the gluing machine, and is fixed with the driver 3, and is used for the impurity removal mechanism for removing impurities on the glued surface of the decorative paper after gluing 6 Installed at the paper outlet of ...

Embodiment 2

[0041] see Figure 10 , this embodiment is further described for Example 1, a high-efficiency automatic detection gluing mechanism for functional decorative paper processing in the illustration, including a gluing roller 1, a pressure roller 2, a pretreatment mechanism 5 and a waste removal mechanism. Mechanism 6, the gluing roller 1 is rotatably installed on the inner wall of the gluing machine, and the two ends of the gluing roller 1 are provided with a driving member 3, and the two ends of the pressure roller 2 are installed with a connecting assembly 4, and through the connecting assembly 4 Installed on the inner wall of the gluing machine, the pretreatment mechanism 5 used to remove impurities on the gluing surface of the decorative paper is installed at the paper inlet of the gluing machine, and is fixed with the driving part 3, and is used for the decorative paper after gluing The miscellaneous mechanism 6 for removing impurities on the glue surface is installed at the ...

Embodiment 3

[0046] see Figure 7-Figure 9 , this embodiment is further described for other embodiments. The adjustment member 15 in the figure includes a rotating sleeve 16 that is rotatably sleeved on the outside of the miscellaneous rod 10. A moving block 17 is fixed on the outside of the rotating sleeve 16, and the inside of the moving block 17 An adjusting rod 18 that is rotatably connected to the inner wall of the adjusting port 9 is threadedly inserted, and a rotating cap 19 is fixed on the outer end of the adjusting rod 18, and an adjusting tooth plate 20 is slidably inserted in the adjusting port 9, and the top of the moving block 17 is fixed There is an adjustment tooth block 21 meshed with the adjustment tooth plate 20;

[0047] Among them, in order to facilitate the opening and closing of the adjustment tooth plate 20, the inner walls of both sides of the adjustment port 9 are provided with limit grooves 29, and both ends of the adjustment tooth plate 20 are fixed with limit bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com