Metal part machining equipment capable of automatically collecting materials

A technology for automatic material collection and processing equipment, which is applied in the direction of metal processing equipment, casting equipment, manufacturing tools, etc. It can solve the problems that processing equipment cannot automatically receive materials, and achieve the effects of avoiding scattering, flexibly adjusting the position, and increasing the opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

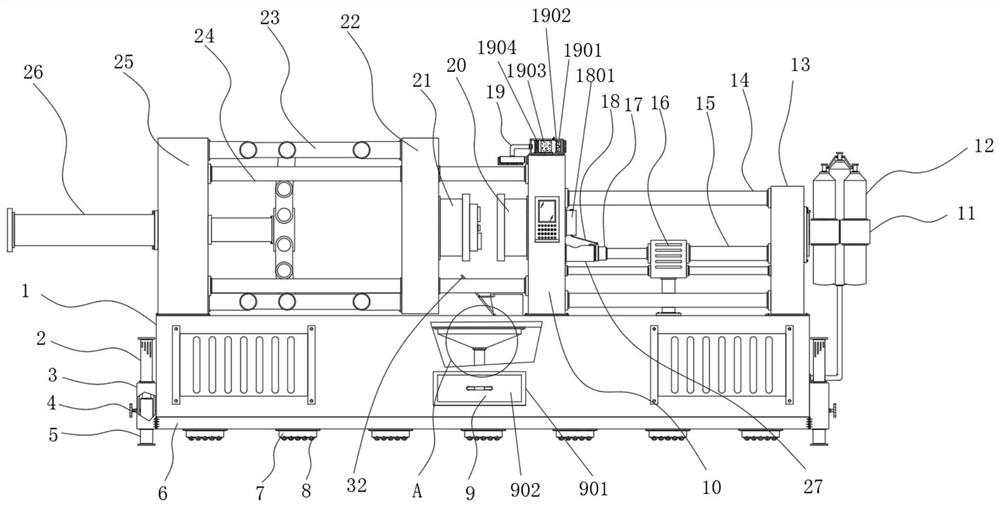

[0041] Example 1: See Figure 1-7 A metal parts processing apparatus, including the cabinet 1, and the top of the casing 1 is provided with a mutually mounted left processing unit, and the left processing unit and the right machining unit are connected by two sets of sliding rods. A automatic receiving device is also provided between the portion and the right machining unit, and the automatic receiving device includes a collecting box 31 and a collecting plate 32, a tank 31 is a tank 1, and a tank 1 of the left opening, and the collecting box 31 The upper surface of the casing 1 is fixed to the upper surface of the box, and the upper left side opening of the collecting box 31 is inclined to the right, and the upper surface of the collecting plate 32 is provided with a sponge pad 33 on the inner surface of the collecting box 31. The plate 32 is hinged to the lower edge of the left opening of the collecting box 31, and the upper portion of the collecting plate 32 is connected to the ...

Embodiment 2

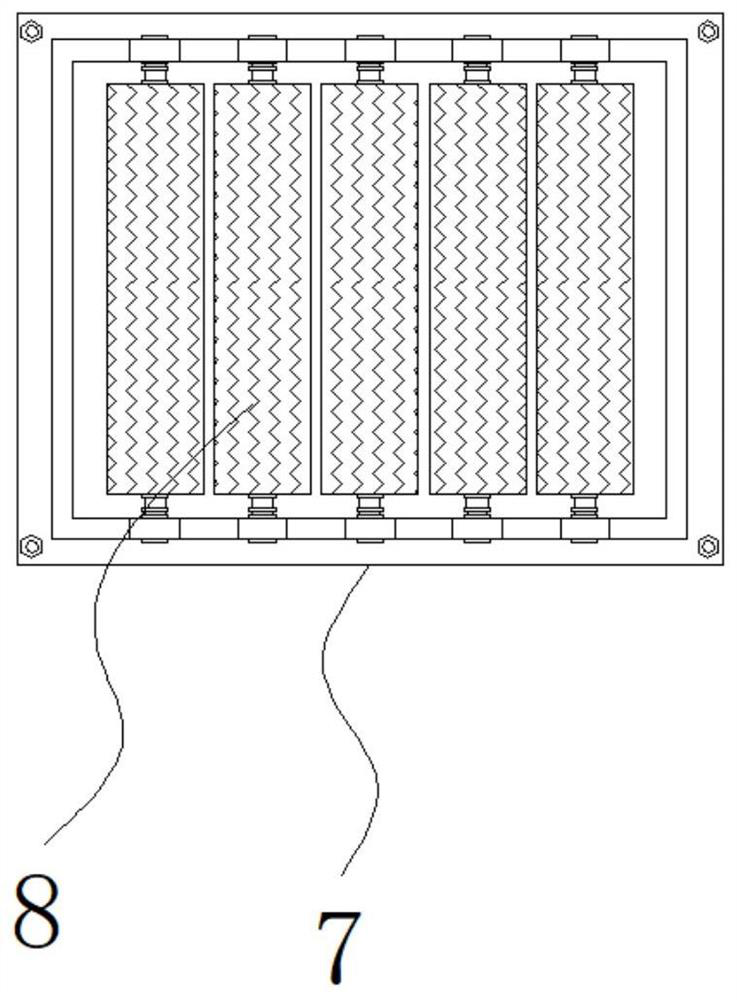

[0043] Example 2: See Figure 1-7 The position adjustment mechanism includes a bottom plate 6, and the bottom plate 6 is fixedly coupled to the bottom end of the casing 1, and the two sides of the bottom plate 6 are fixedly connected to the fixed sleeve 3, respectively, and the top end of the fixed sleeve 3 is fixedly connected to the first hydraulic cylinder 2, which The specific model of the first hydraulic cylinder 2 can be SC150 * 500, and the inside of the fixing sleeve 3 is provided with a support pin 5, and the bottom end of the first hydraulic cylinder 2 extends to the inside of the fixed sleeve 3 and fixed to the top of the support foot 5. The connection, the side of the fixed sleeve 3 is inserted with a fixed hand wheel 4, and the bottom end of the bottom plate 6 is fixedly connected to the plurality of sets of fixed block 7, and the internal activity of the bottom end of the fixed block 7 has a five-component sliding roller 8;

[0044] The fixing block 7 is arranged as a...

Embodiment 3

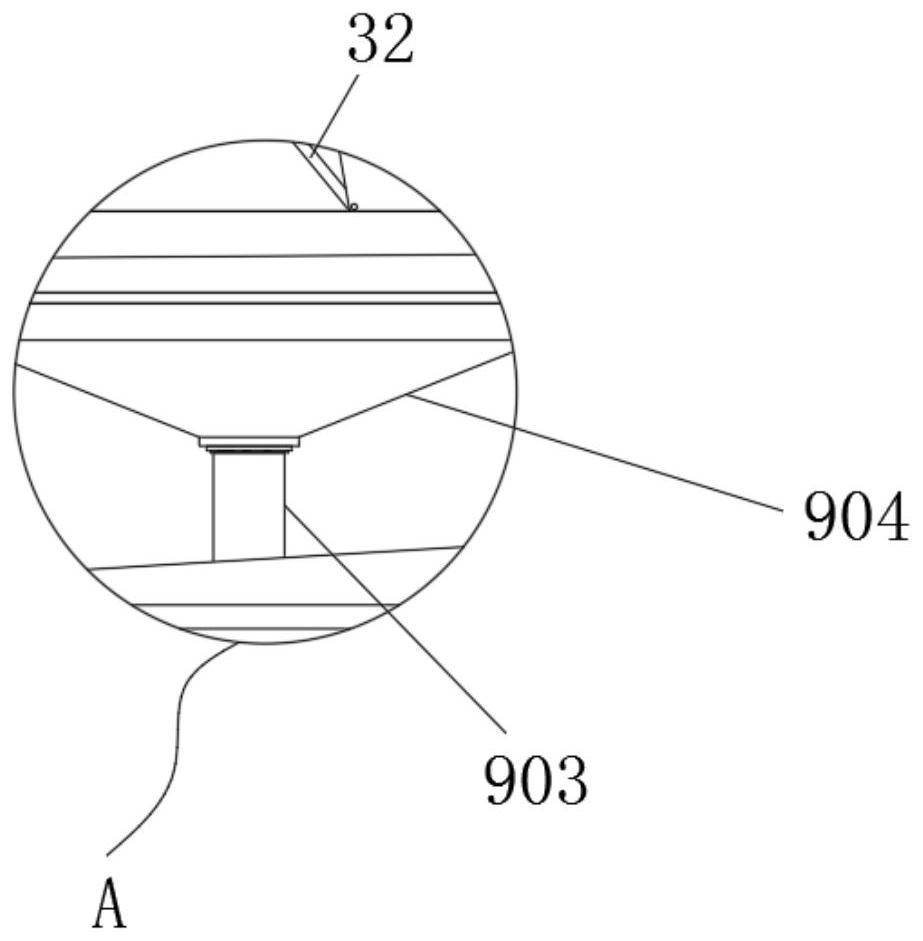

[0046] Example 3: The bottom end of the casing 1 is provided with a dropping collecting structure 9, and the drip collection structure 9 is composed of a fixed groove 901, a reservoir drawer 902, a conduit 903, and a concentrate funnel 904, and the fixed slot 901 is disposed in the casing. 1 The bottom of the inside, the inside of the fixed slot 901 is inserted with a reservoir drawer 902, and the liquid funnel 904 is fixedly attached to the top end of the interior of the casing 1, and the top end of the fixed slot 901 and the bottom end of the collector funnel 904 are fixedly connected. There is a catheter 903;

[0047] The liquid funnel 904 penetrates through the top end of the box 1 and extends to the outside, and the top end of the collector funnel 904 is lower than the bottom end of the sliding retention seat 22, and the internal communication between the conduit 903 and the fixed slot 901;

[0048] Specifically, such as figure 1 with image 3 As shown, when the machine starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com