Inflation assembly for wear-resistant air bag during collision

A technology of air bags and components, applied in the direction of preventing mechanical damage, containers, transportation and packaging, etc., to achieve the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

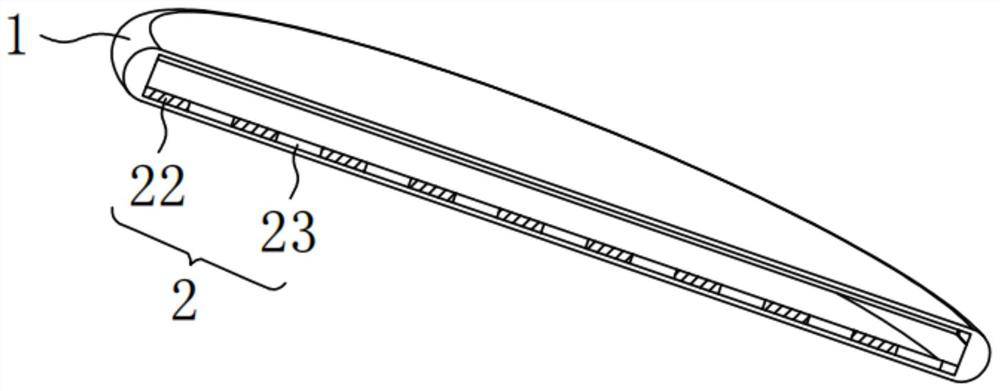

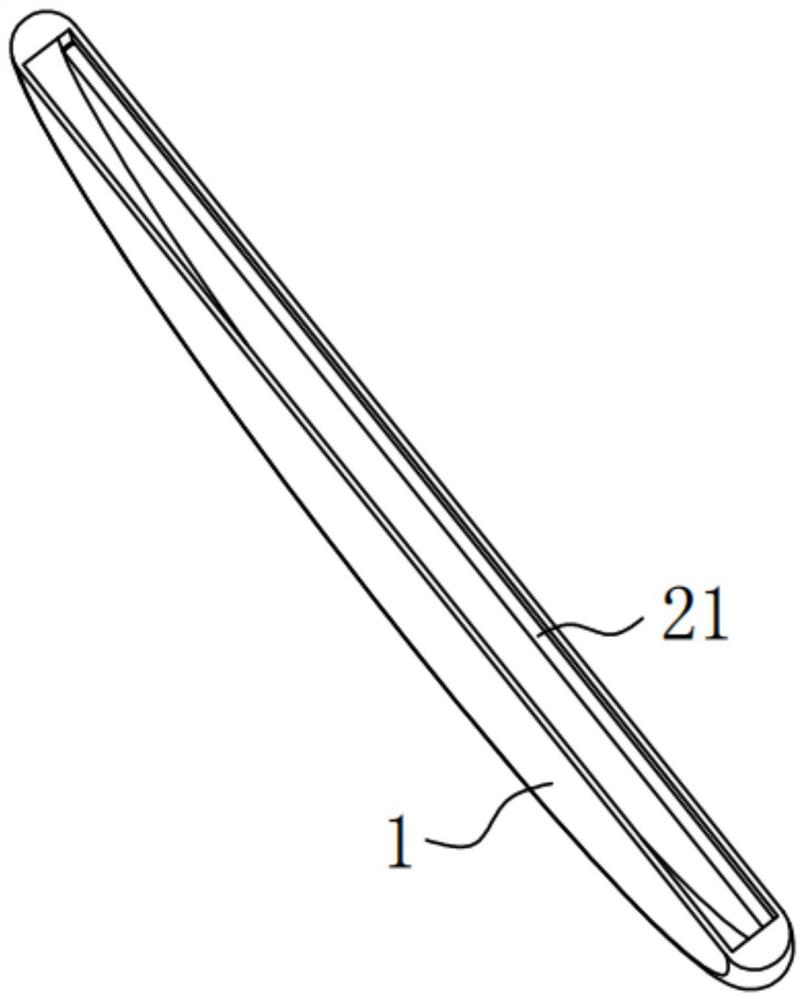

[0033] The water inside the water storage bag 21, the baking soda block 22 and the citric acid block 23 are made according to the following weight ratio of 1:3:2.

no. 2 example

[0035] The water inside the water storage bag 21, the baking soda block 22 and the citric acid block 23 are made according to the following weight ratio: 2:2:3.

no. 3 example

[0037] The water inside the water storage bag 21, the baking soda block 22 and the citric acid block 23 are made according to the following weight ratio of 4:6:5.

[0038] For the test of the filling state, filling time and material waste of the wear-resistant air bag prepared in Examples 1-3, for the convenience of comparison, the data of all examples are summarized as follows:

[0039] Table 1

[0040] Filling state (%) Filling time (S) Material waste (%) first embodiment 87% 1.8 3% second embodiment 98% 2 2% third embodiment 97% 2.5 8%

[0041] As can be seen from the above table, since the filling state, filling time and material waste test results of the wear-resistant air bag prepared in Example 2 are higher than those of the other examples, the wear-resistant air bag given in Example 2 is the best choice .

[0042] Different proportions will result in different time and volume of carbon dioxide generation. The ratio of solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com