Water-based base film primer and preparation method and application thereof

A water-based, base-film technology, used in coatings, surface pretreatment, devices for coating liquids on surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The present embodiment has prepared a kind of water-based base film primer, and concrete raw material composition is as shown in table 1, and concrete process is:

[0091] S1. Stir all the raw materials of component A in Table 1 at a speed of 1300 rpm for 4 minutes to obtain component A;

[0092] S2. Stir all the raw materials of component B in Table 1 at a speed of 1300 rpm for 4 minutes to obtain component B;

[0093] S3. According to the mass ratio of component A: component B = 3:1, mix component A and component B and stir clockwise fully to form a water-based base film primer.

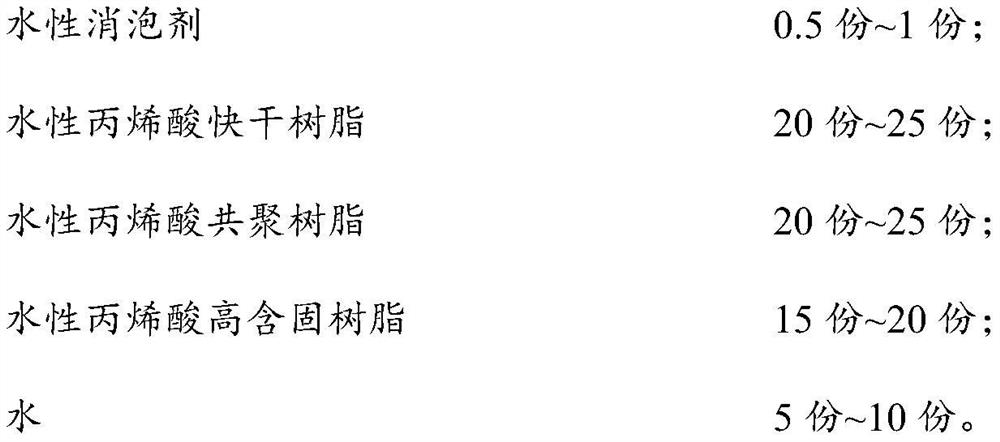

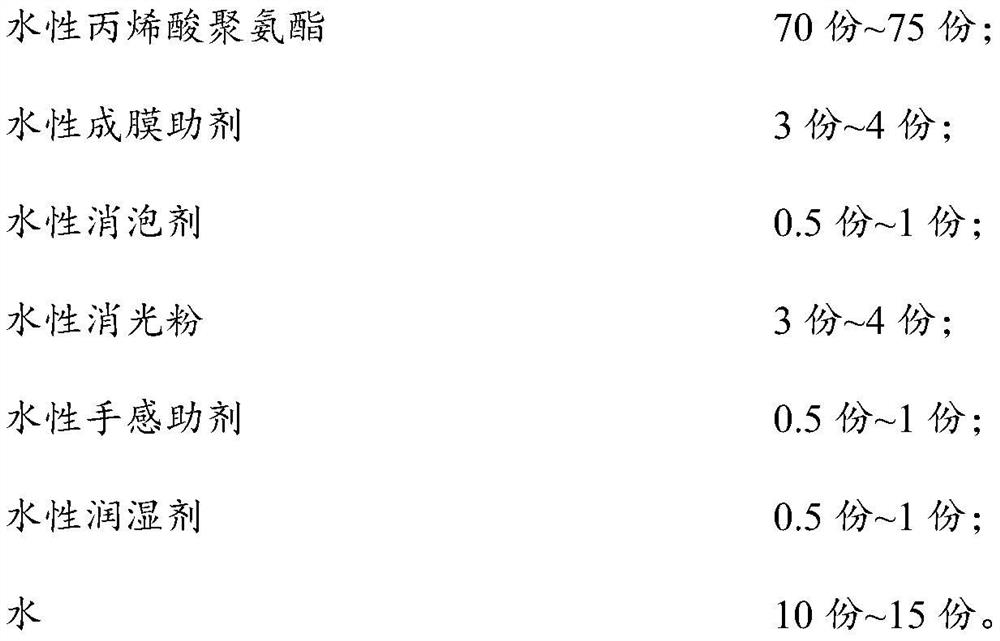

[0094] The preparation raw material of water-based base film primer in table 1 embodiment 1

[0095]

[0096]

Embodiment 2

[0098] The present embodiment has prepared a kind of water-based base film primer, and the specific difference with embodiment 1 is:

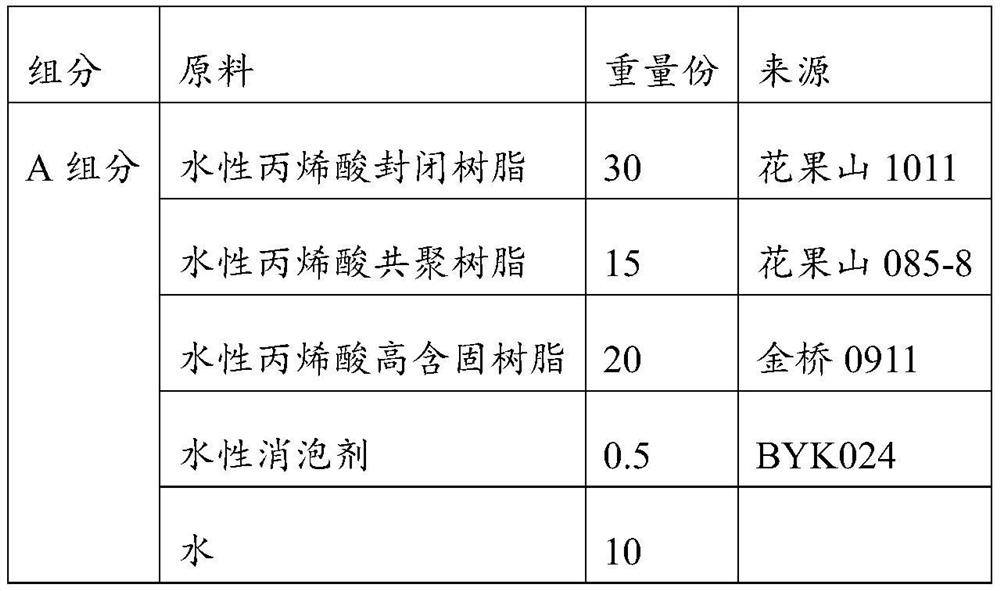

[0099] (1) The composition of raw materials for the preparation of component B is different, and the specific raw material composition is shown in Table 2.

[0100] The preparation raw material of water-based base film primer B component in table 2 embodiment 2

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com