A bridge support height adjustment system

A bridge bearing and height adjustment technology, applied in bridges, bridge construction, bridge parts, etc., to ensure stability, improve adjustment efficiency, and achieve the effect of fully automatic height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

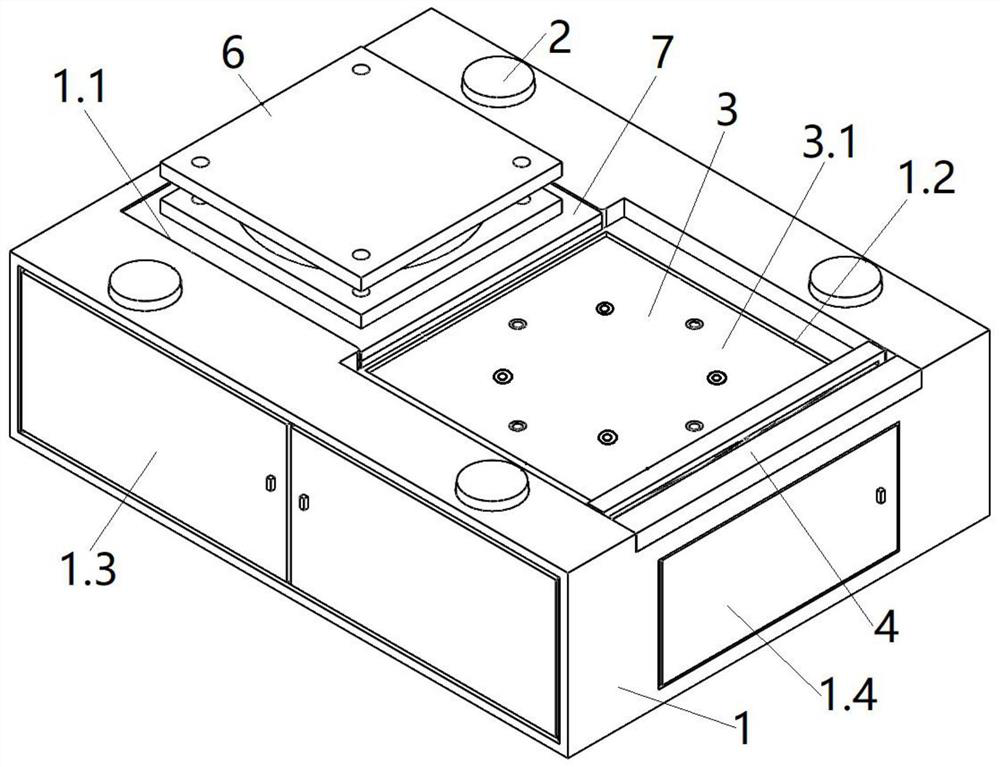

[0043] see Figure 1 to Figure 11 , a bridge bearing height adjustment system, this embodiment is applied to the automatic adjustment of the height of bridges and bridge bearings.

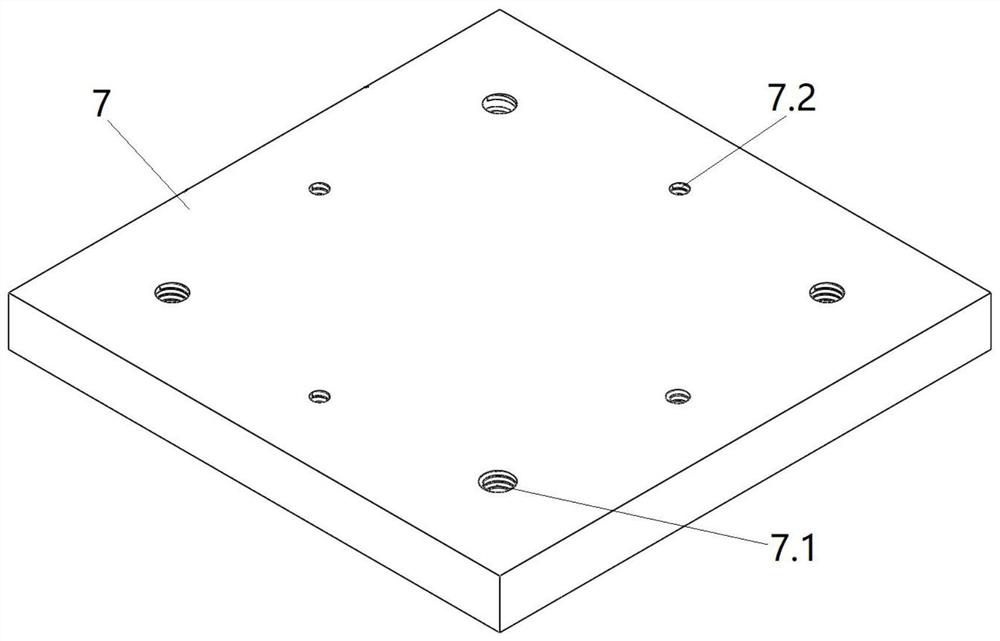

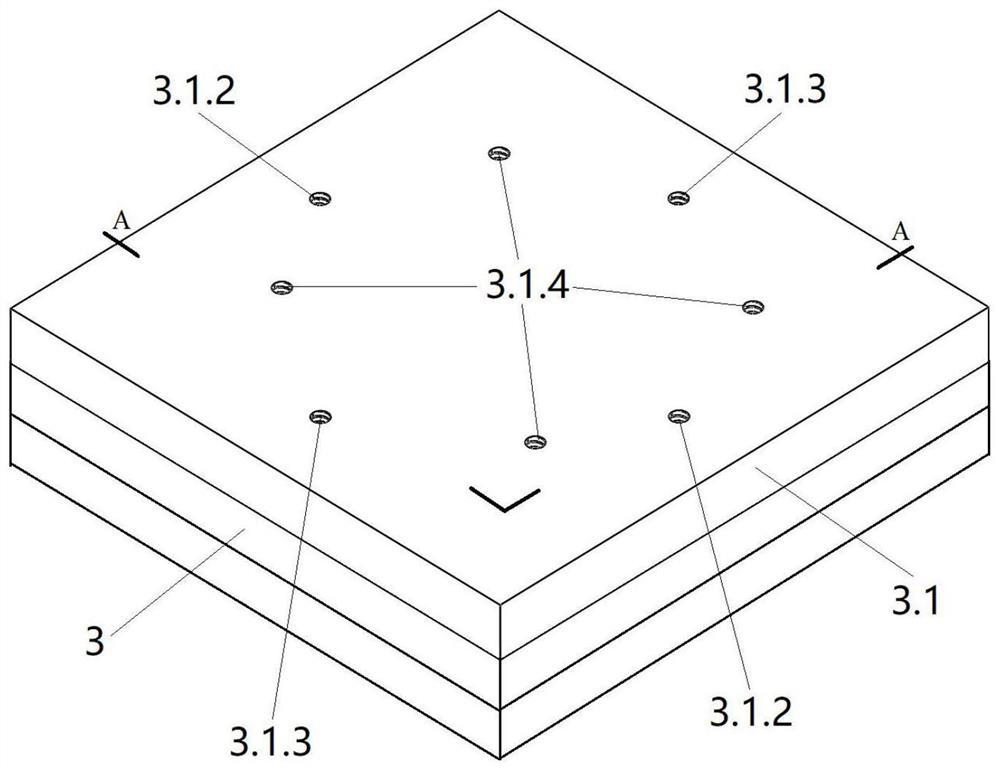

[0044] A bridge bearing height adjustment system, see figure 1 , including a base 1 and a jacking device 2, an adjusting backing plate assembly 3 and a telescopic mechanism 4 arranged on the base 1; the base 1 is provided with a bridge support connecting part 1.1 and a backing plate accommodating part 1.2, the top and The bridge support 6 connected by the bridge is detachably arranged on the bridge support connecting part 1.1, one side of the bridge support connecting part 1.1 is provided with an opening communicating with the backing plate accommodating part 1.2, and two parts of the opening are provided. The side is provided with an arc-shaped anti-collision part 1.5; the four jacking devices 2 are evenly distributed around the base 1, and the end (ie the top) of the jacking device 2 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com