Drain board with high pressure resistance

A kind of technology of drainage board and board body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

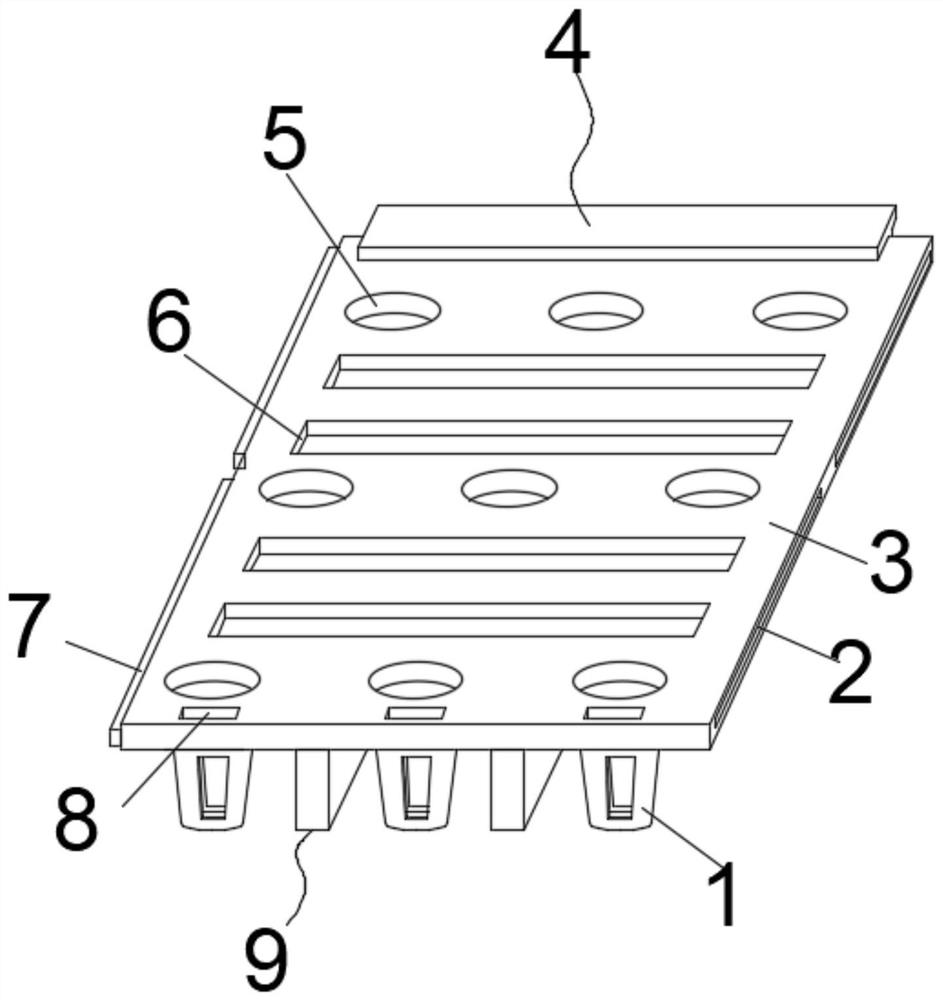

[0035] The outer surface of the upper end of the plate body 3 is provided with three groups of circular notches 5, and the outer surface of the upper end of the plate body 3 is located between the two groups of circular notches 5 and is provided with a bar-shaped notch 6. The setting of the shaped notch 6 makes the water body pass through the plate body 3, thereby being discharged from the bottom of the plate body 3, and the drainage operation is completed.

[0036] Support frame 9 comprises two groups of first clamping plates 18 and two groups of second clamping plates 19, and is fixed by thermoplastic welding between two groups of first clamping plates 18 and two groups of second clamping plates 19, and the cross section of support frame 9 is The well-shaped structure, utilizing the setting of the support frame 9, can support and fix the bottom of the support seat 1 when the support seat 1 is installed, thereby improving the structural strength of the support seat 1 and incre...

Embodiment 2

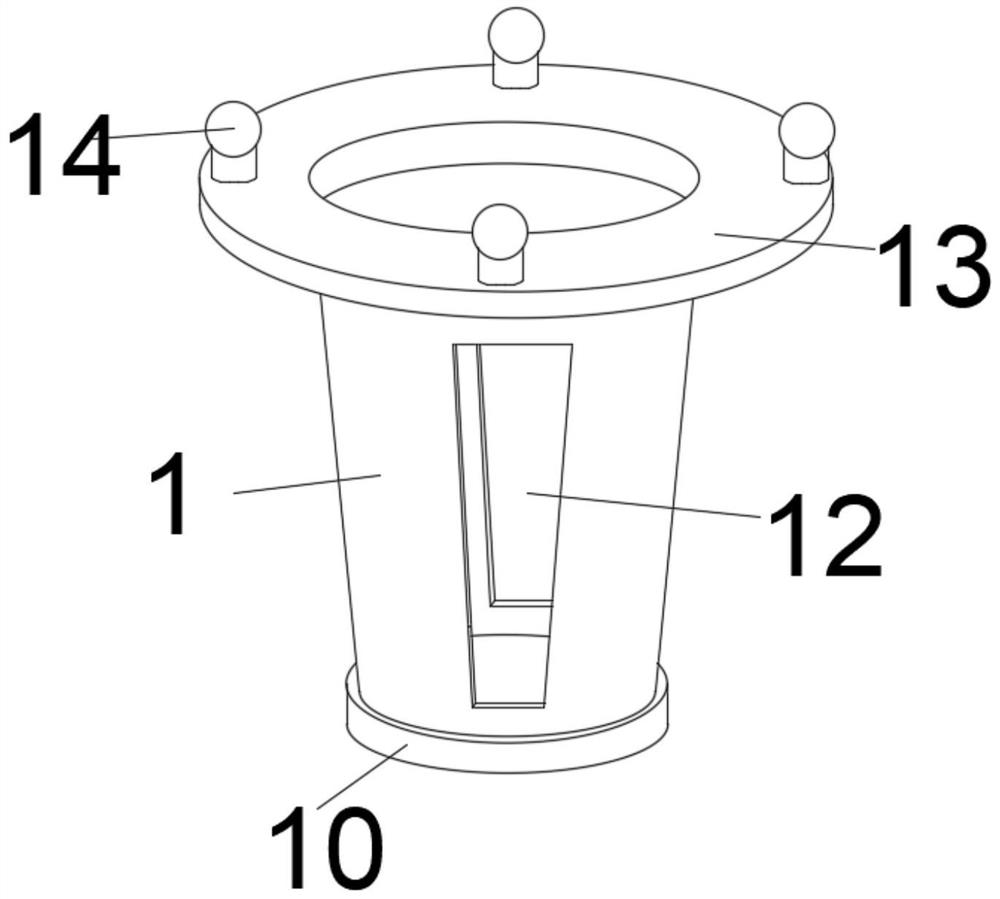

[0040] Two groups of drainage grooves 12 are provided through the side outer surface of the support seat 1, and the two groups of drainage grooves 12 are arranged side by side. Four groups of docking plugs 14 are installed on the upper part of the fixing ring 13, and the fixing ring 13 cooperates with the docking plugs 14 to support The installation of the seat 1 plays the role of splicing and fixing, and at the same time, the setting of the drainage groove 12 is used to make the support seat 1 have a side drainage structure.

[0041] Two sets of splicing grooves 2 are provided on the inner side of one end of the plate body 3, and two sets of splicing clips 7 are fixedly installed on the other end of the plate body 3. By using the setting of the splicing grooves 2 and the splicing clips 7, it is possible to facilitate the connection between the two groups of plate bodies 3. Splicing and fixing between.

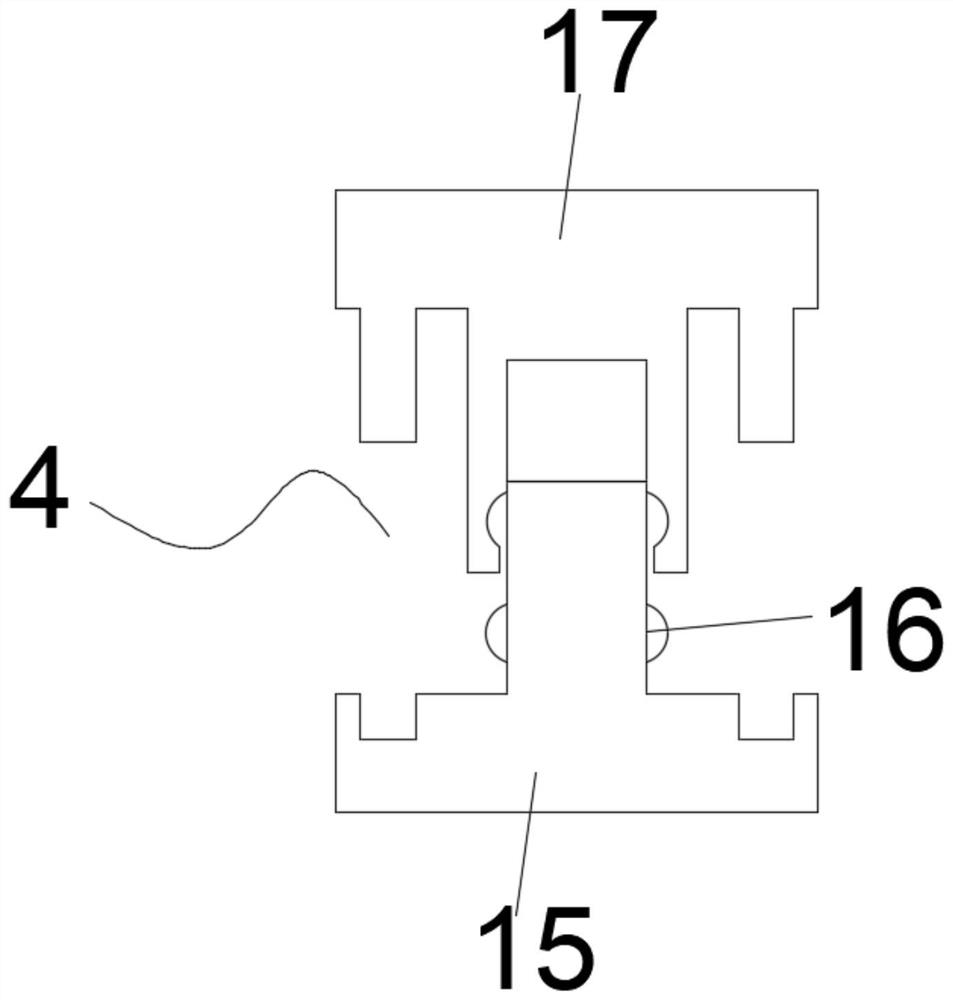

[0042] The combination clip 4 comprises an upper clip 17 and a lower clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com