Device and method for testing blasting performance of liquid cooling plate

A test device and liquid cold plate technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as product rupture, no protective measures, and inability to guarantee the accuracy of test results, etc. , to achieve the effects of safe booster blasting process, fast booster blasting time, and reduced risk of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now, the present invention will be described in further detail in conjunction with specific embodiments and accompanying drawings. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but these examples are not intended to limit the protection scope of the present invention. Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of the present invention. "In one embodiment" appearing in different places in this specification does not all refer to the same embodiment, nor is it a separate or selective embodiment that is mutually exclusive with other embodiments.

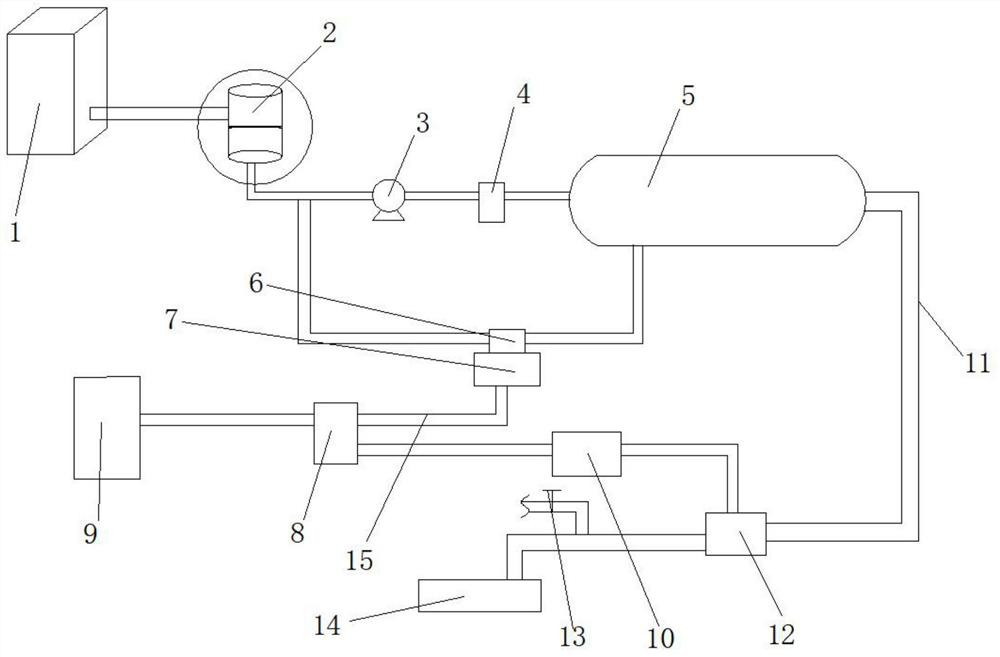

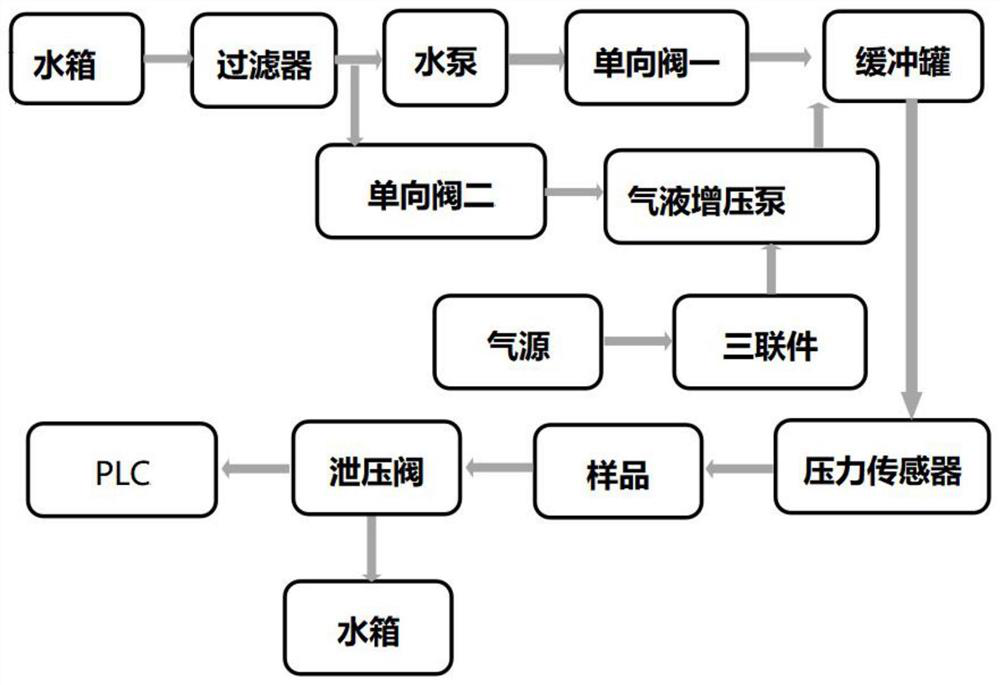

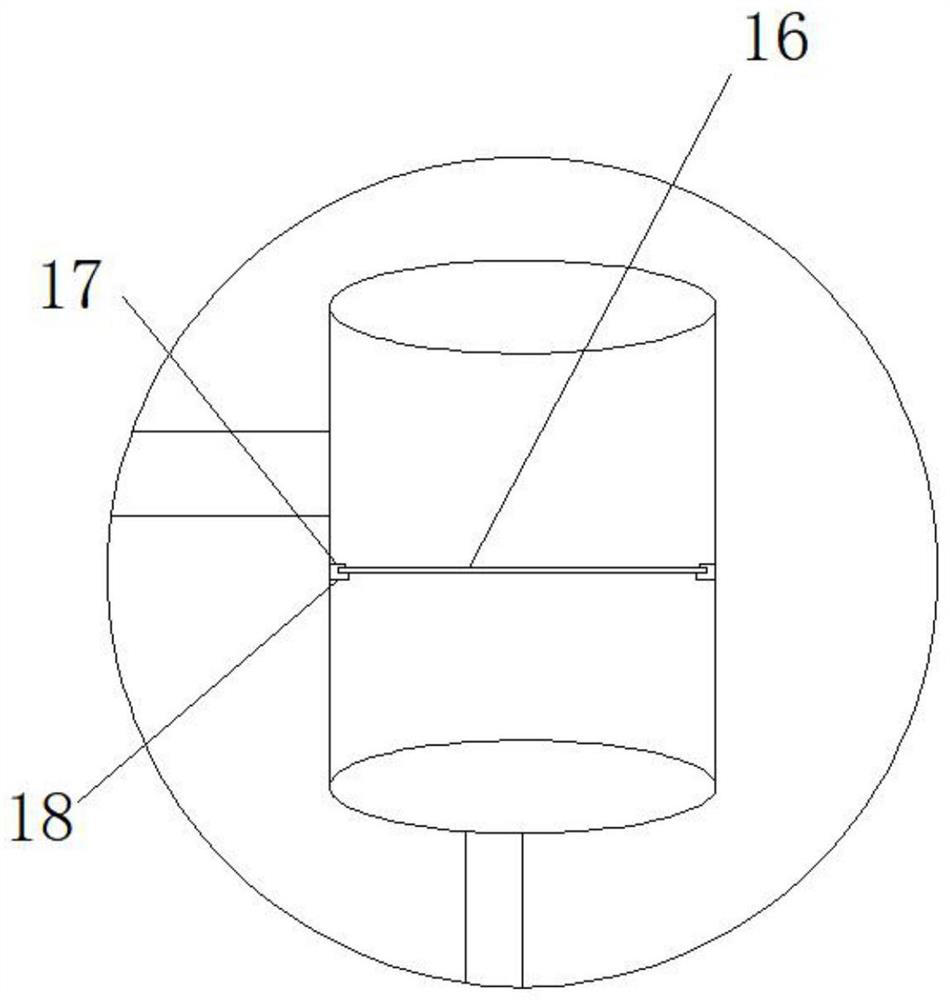

[0034] see figure 1 , figure 2 and image 3 , a liquid-cooled plate blasting performance test device, comprising a water supply tank 1, a water pump 3, a one-way valve 4 and a buffer tank 5 connected in sequence through pipelines, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com