Method of controlling an industrial system, control system and industrial system

A technology for industrial systems, control systems, applied in general control systems, control/regulation systems, manufacturing tools, etc., to solve problems such as damage, robot program failure, material temperature fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, a method of controlling an industrial system including at least one agent, a control system for controlling an industrial system including at least one agent, and an industrial system including the control system will be described. The same reference numerals will be used to denote the same or similar structural features.

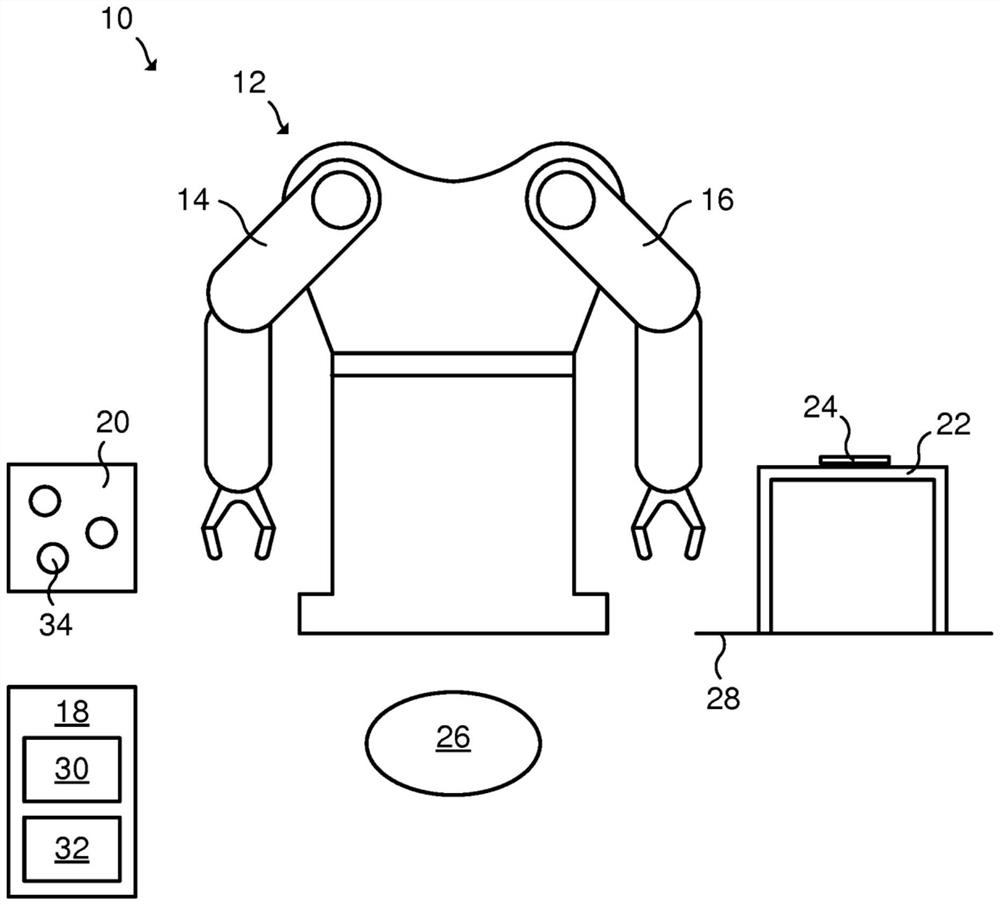

[0038] figure 1An illustrative example of an industrial system 10 is schematically represented. The industrial system 10 of this example includes an industrial robot 12 having two manipulator arms 14 , 16 . The example industrial system 10 further includes a control system 18 , a feeder 20 , a table 22 , a coaster 24 on the table 22 , and a waste bin 26 . The table 22 is positioned on the floor 28 . The two arms 14, 16 of the robot 12 constitute an agent with discrete agent states. Thus, the industrial system 10 includes a first agent in the form of a left arm 14 and a second agent in the form of a right arm 16 . However, industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com