Friction assembly

A technology of structural components and friction plate sets, which is applied in the direction of friction linings, friction clutches, brake components, etc., can solve the problems of high energy and temperature loads of friction materials, high friction coefficients, and limited structural dimensions of clutches, etc., to achieve improved thermal performance. The effect of load capacity and rapid heat dissipation

Active Publication Date: 2021-10-15

MIBA FRICTEC

View PDF34 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The structural size of the clutch is also strongly limited by the requirement to keep the vehicle weight as low as possible

This in turn has a strong influence on the load on the friction linings, since the small installation space for the clutch means a smaller lining surface, which results in higher energy and temperature loads on the friction material

[0005] Metallic friction linings are highly energy- and thermal-loadable, have a high coefficient of friction and low wear, but are also very strongly prone to frictional vibrations, which can affect the entire drive train and thus have a negative impact on the driving comfort of the vehicle have a very negative impact

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0089] 60.0% copper, 10.0% iron, 15.0% feldspar, 10.5% synthetic graphite, 4.5% alumina

example 2

[0091] 60.0% copper, 2.0% tin, 20.0% diatomaceous earth, 12.0% synthetic graphite, 2.0% natural graphite, 4.0% corundum

example 3

[0093] 60.0% copper, 14.0% iron, 8.0% mica, 10.5% synthetic graphite, 3.0% natural graphite, 4.5% alumina

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

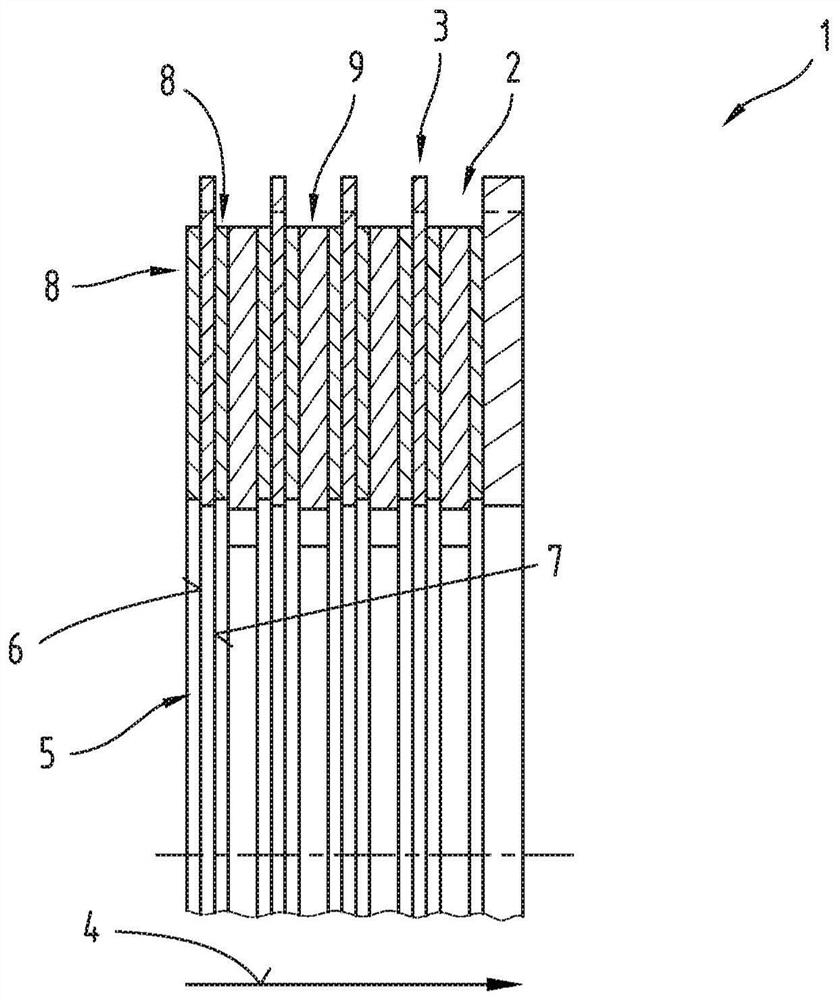

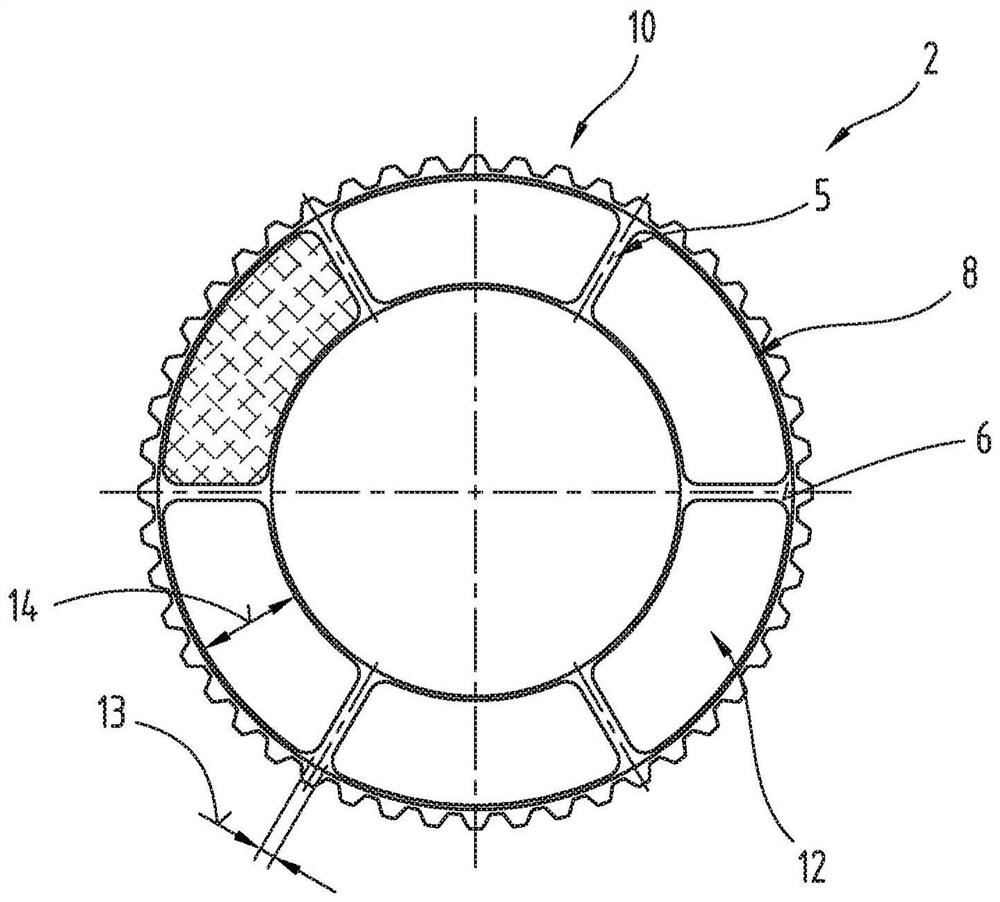

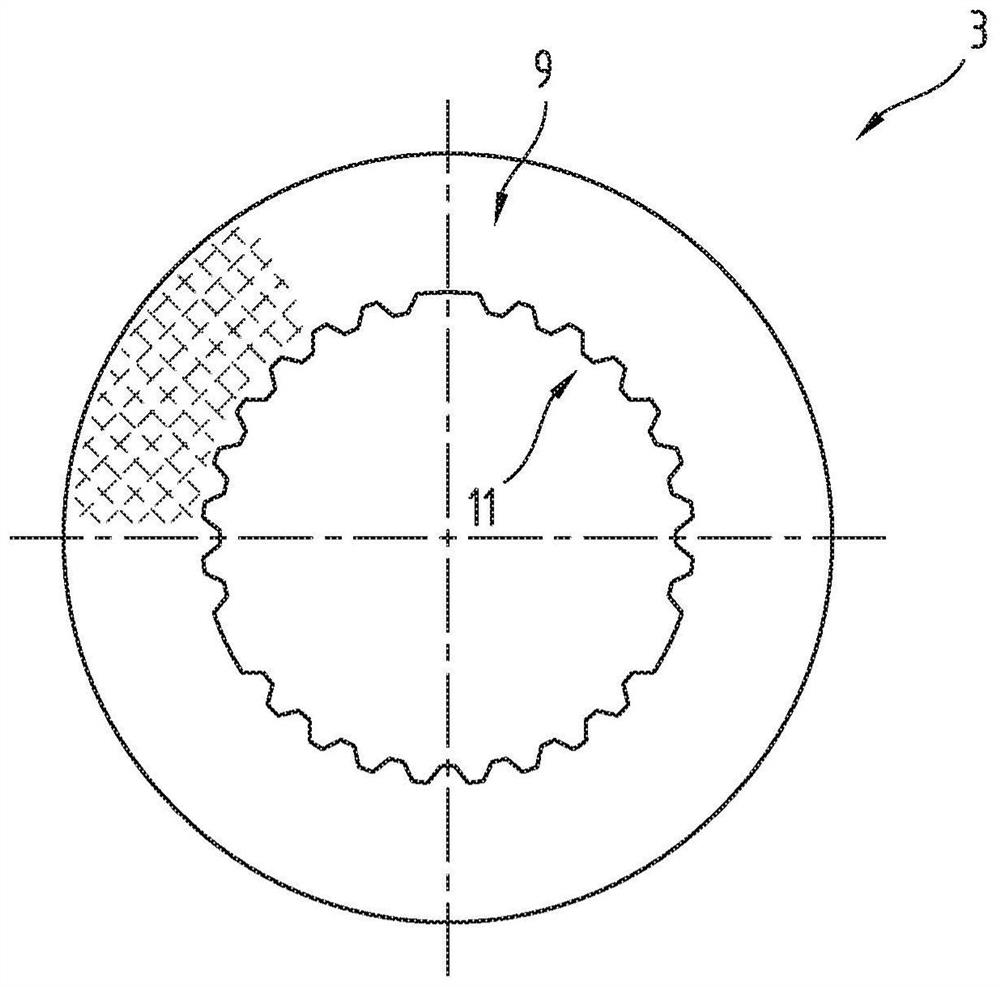

The invention relates to a friction assembly which comprises a dry clutch plate set (1) with at least one friction lining plate (2) and at least one counterplate (3) that are alternately successively arranged in an axial direction (4) of the plate set (1) and that can be frictionally engaged with each other, the friction lining plate (2) having at least one molded dry friction lining.

Description

technical field [0001] The invention relates to a friction structure assembly comprising a dry-running disk pack having at least one lining friction disk and at least one counter-disc lining along the The axial directions of the disk sets are arranged alternately one behind the other and the lining disks and the counter disks can be brought into frictional engagement with one another, the lining disks having at least one dry-running friction lining. Furthermore, the invention relates to the use of said friction structure assembly. Background technique [0002] In conventional dry-running drive systems of motor vehicles, mainly organic resin-bonded friction linings are used. [0003] For example DE2924540A describes a product for the manufacture of constructional elements with a metallic The carbon content of the fiber powder is between 0.95% and 1.10% by weight and the chromium content of the steel fiber powder is between 1.3% and 1.6% by weight. The fine distribution of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): F16D13/64

CPCF16D13/648F16D2200/0004F16D2200/0034F16D2200/006F16D2200/0086F16D2250/0023F16D65/127F16D69/027F16D2069/004F16D2069/005F16D2200/0026F16D2200/0073

Inventor M·米尔勒格尔F·尼克尔

Owner MIBA FRICTEC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap