Patents

Literature

32results about How to "Reduce vibration friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

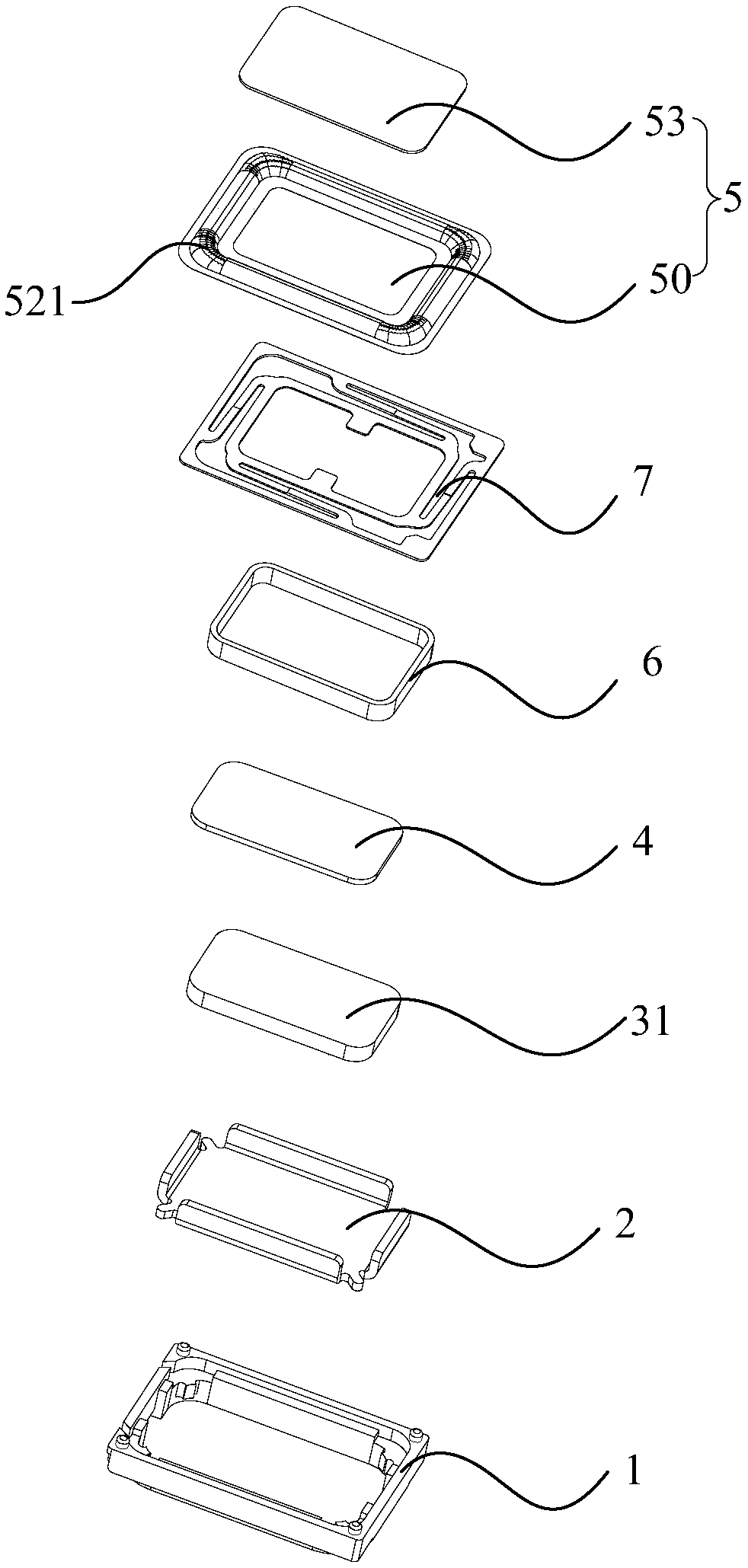

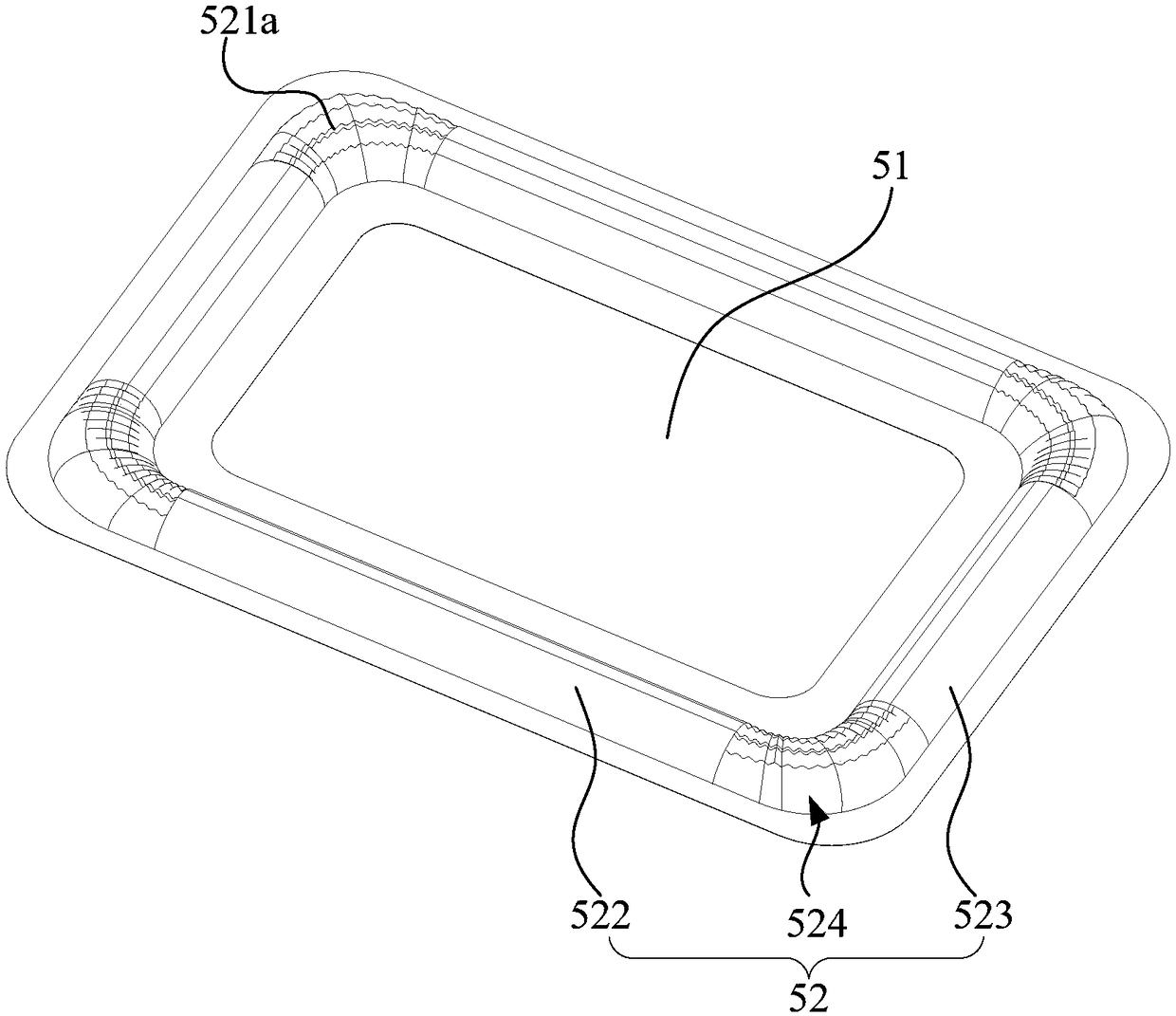

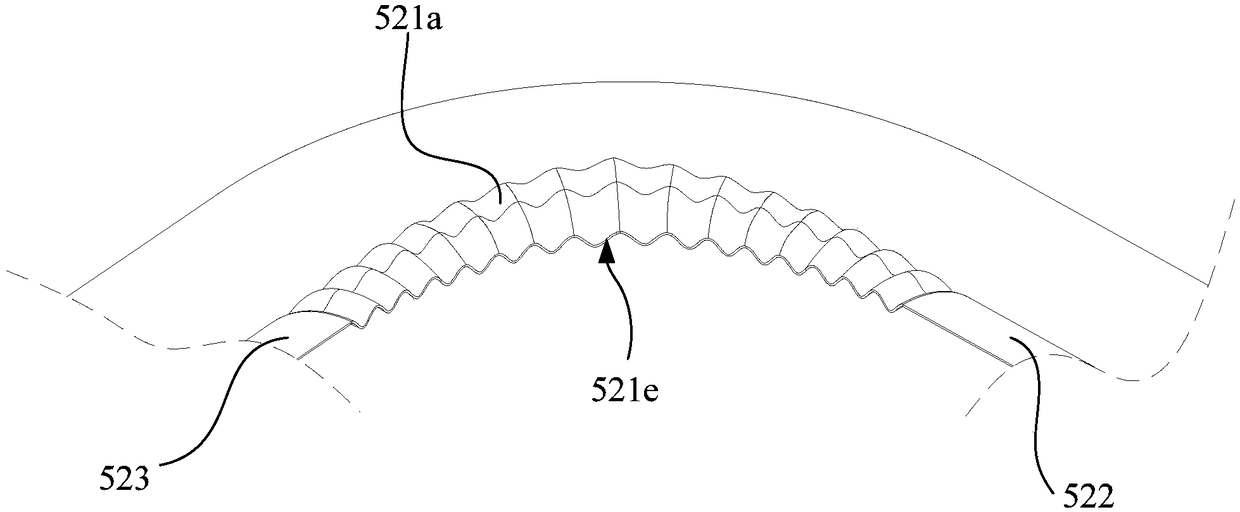

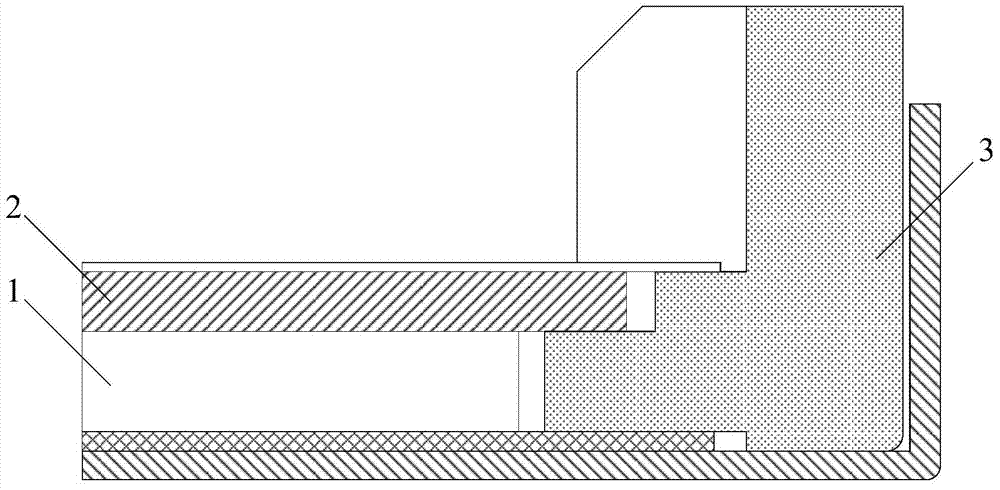

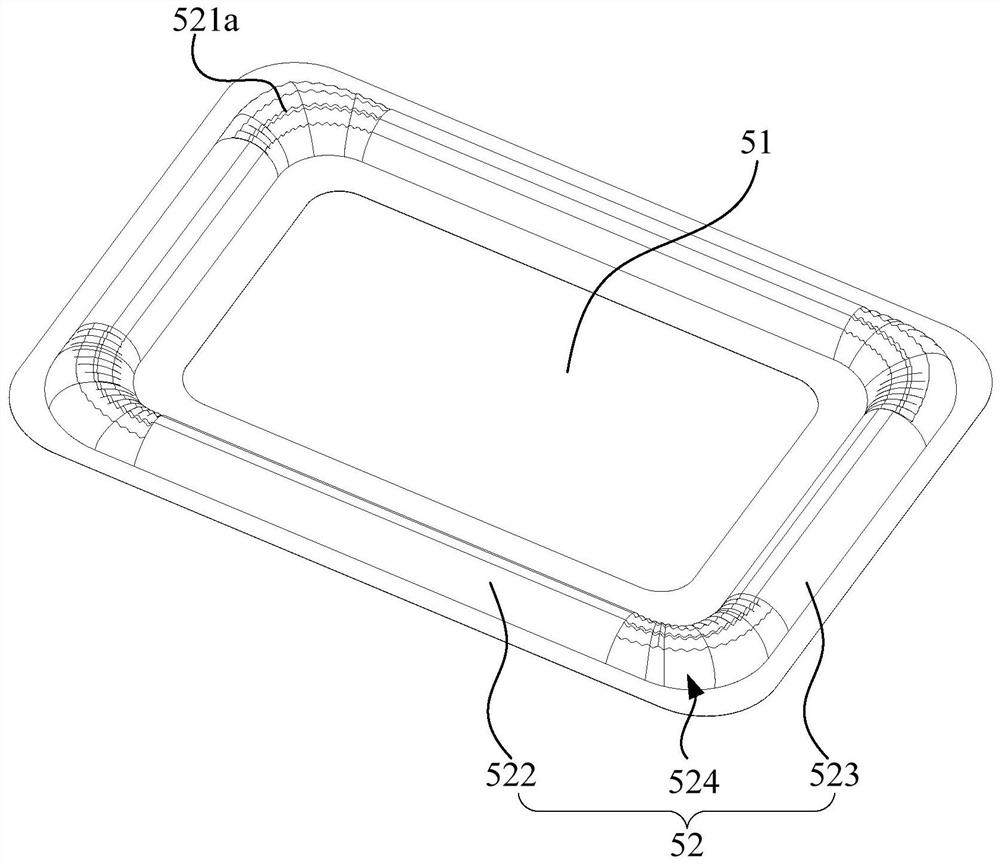

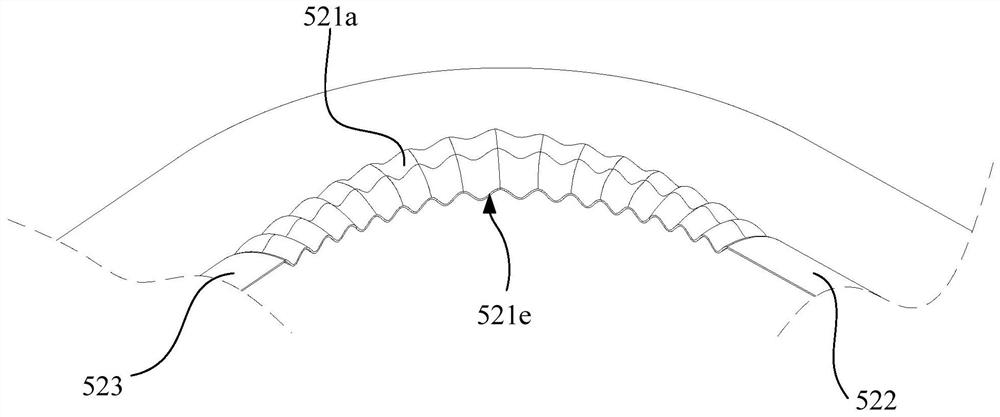

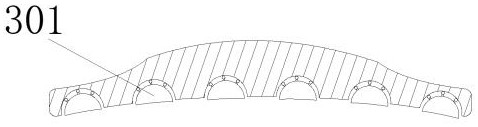

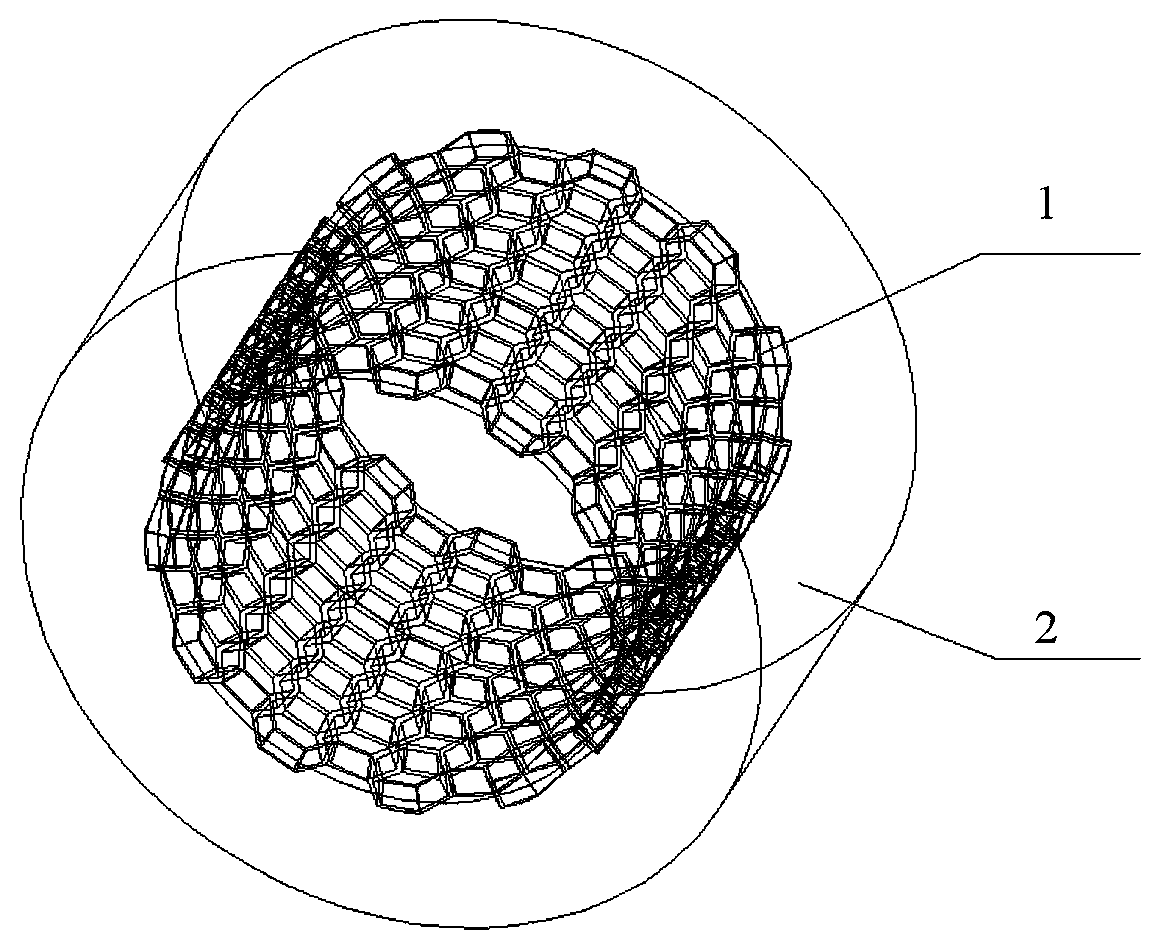

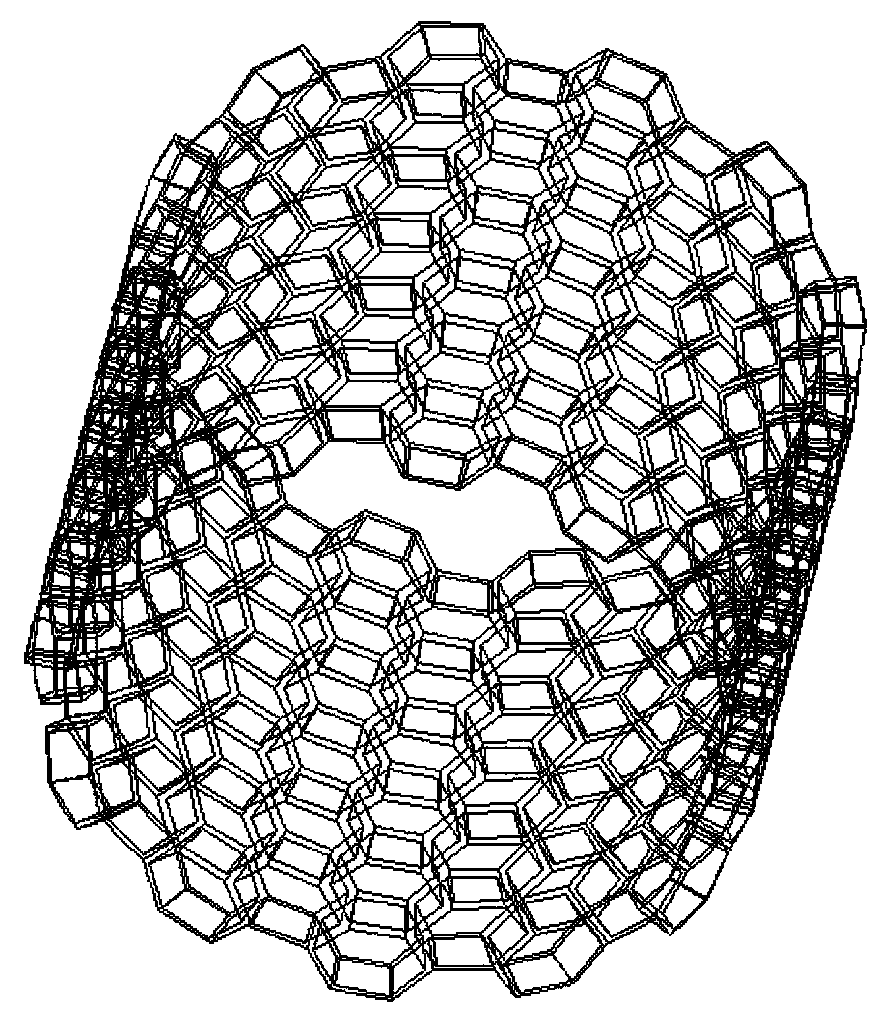

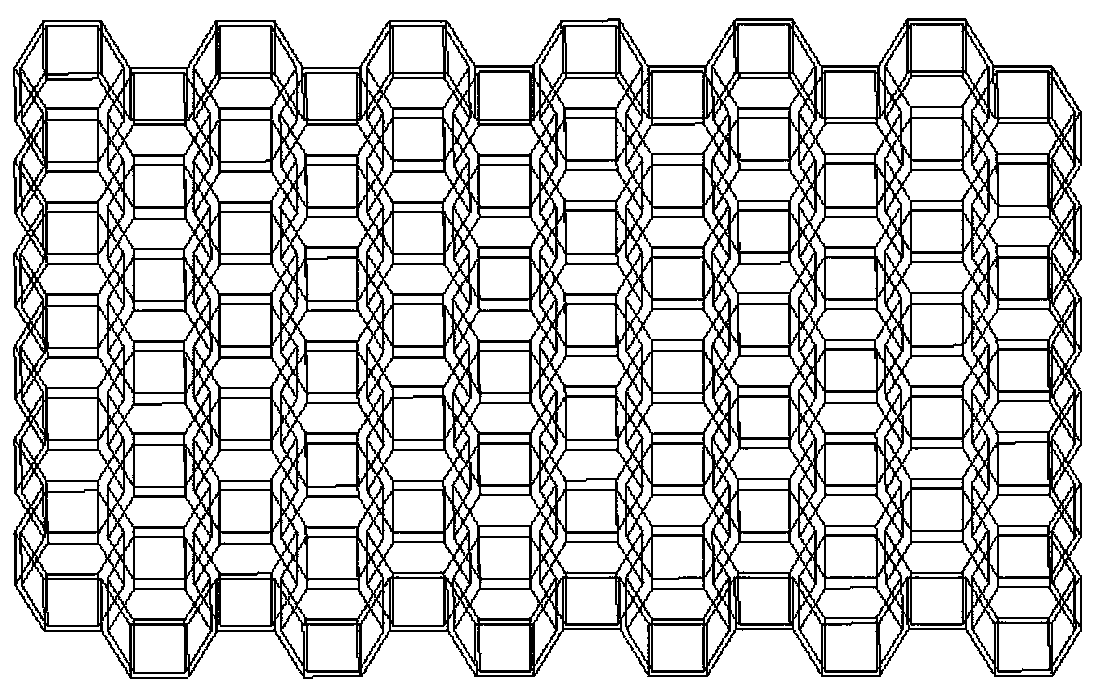

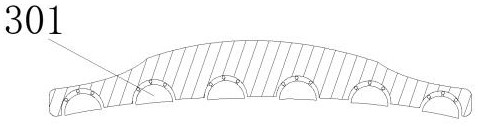

Vibrating diaphragm and loudspeaker

ActiveCN108900955ASmooth vibrationReduce vibration frictionNon-planar diaphragms/conesStress concentrationCrest line

The invention discloses a vibrating diaphragm and loudspeaker, wherein the vibrating diaphragm includes an intermediate part and a folding ring part surrounding the periphery of the intermediate part,the folding ring part includes a first straight side part, a second straight side part, and an arc-shaped corner part connecting the first straight side part and the second straight side part, the arc-shaped corner part and end parts of the first straight side part and the second straight side part which are connected with the arc-shaped corner part form a corner area; a pattern is arranged on the corner area, the pattern extends in an up-down undulating shape along a surrounding direction of the folding ring part in the position of the pattern and has a plurality of crest lines and trough lines, the cross section of the pattern along the surrounding direction of the folding ring part in the position of the pattern is arranged to be a continuously bent smooth curve, and the smooth curve has a plurality of crest lines and trough lines. Through the technical scheme of the invention, the stress concentration phenomenon of the folding ring part of the vibrating diaphragm can be reduced and the performance reliability and acoustic performance of the loudspeaker can be improved.

Owner:GOERTEK INC

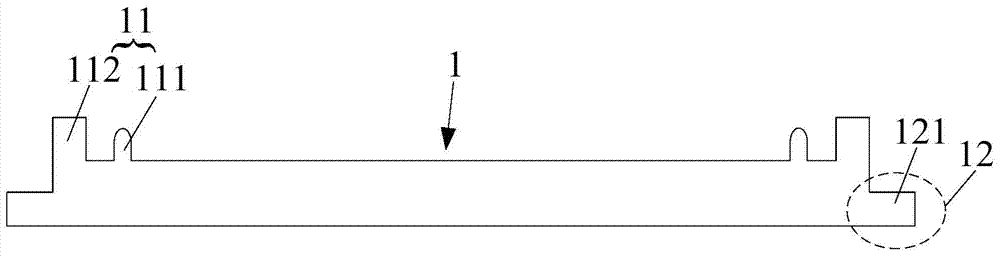

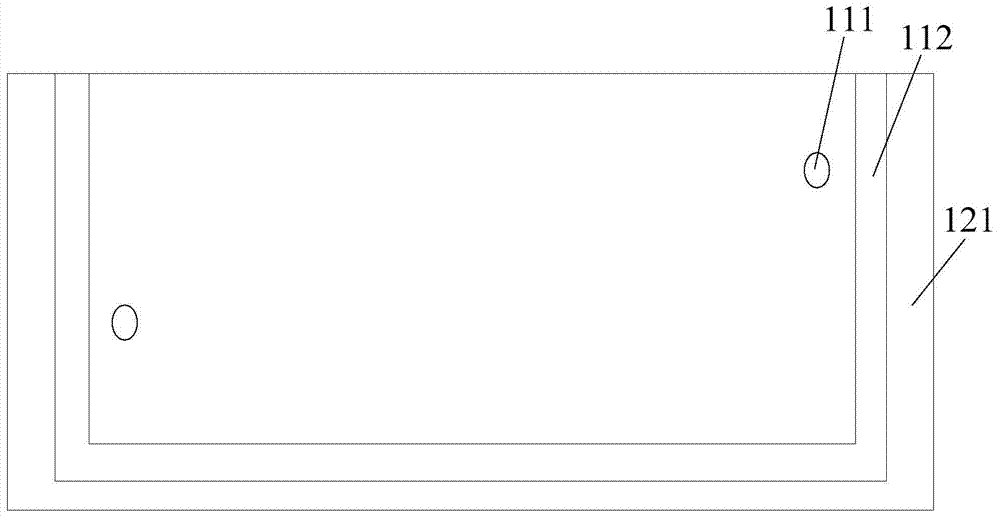

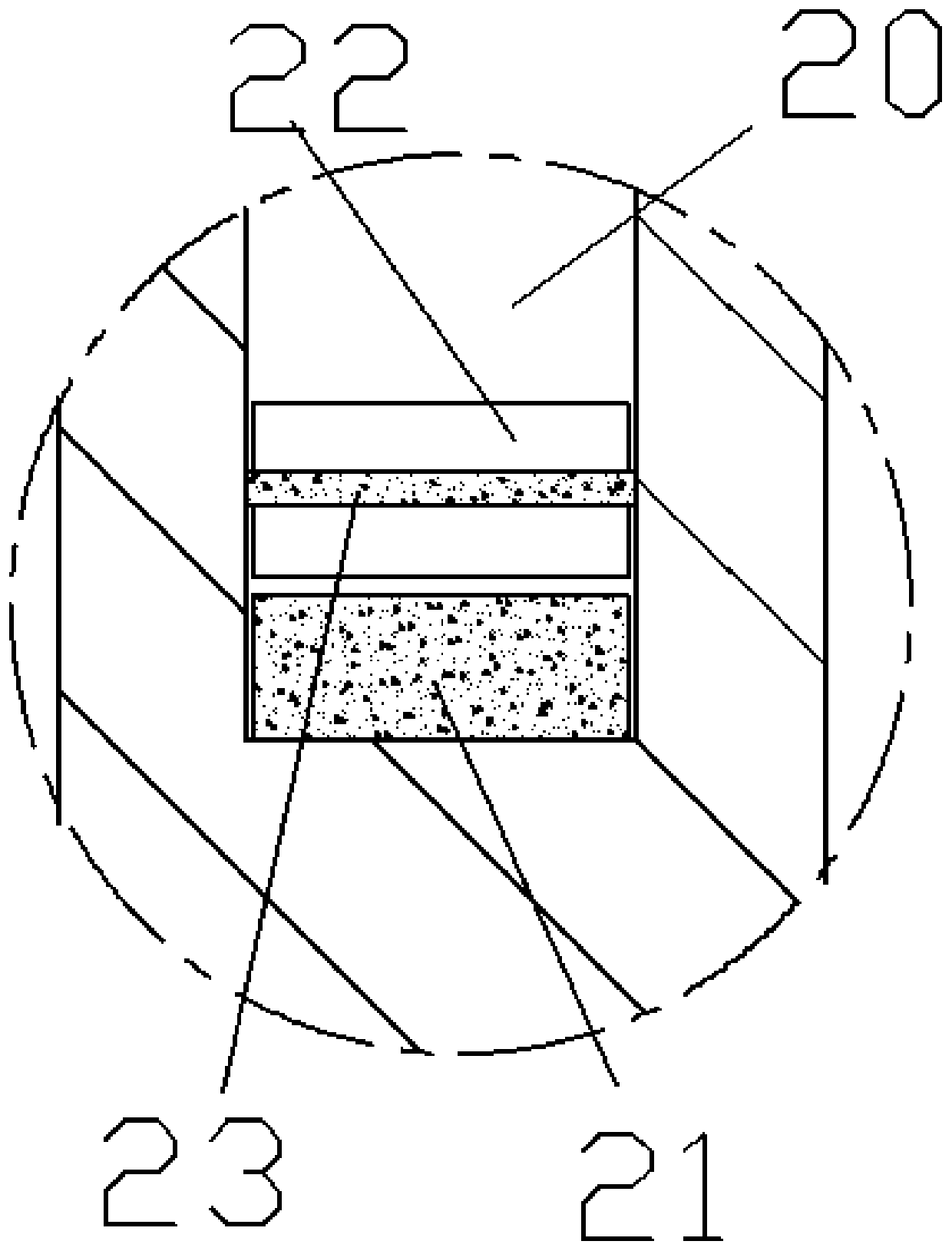

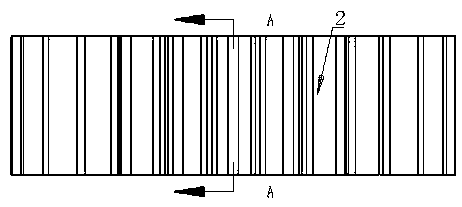

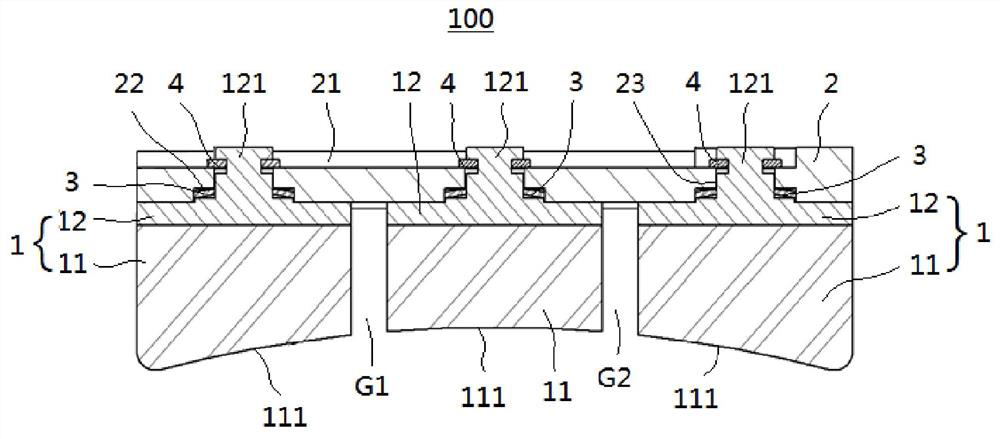

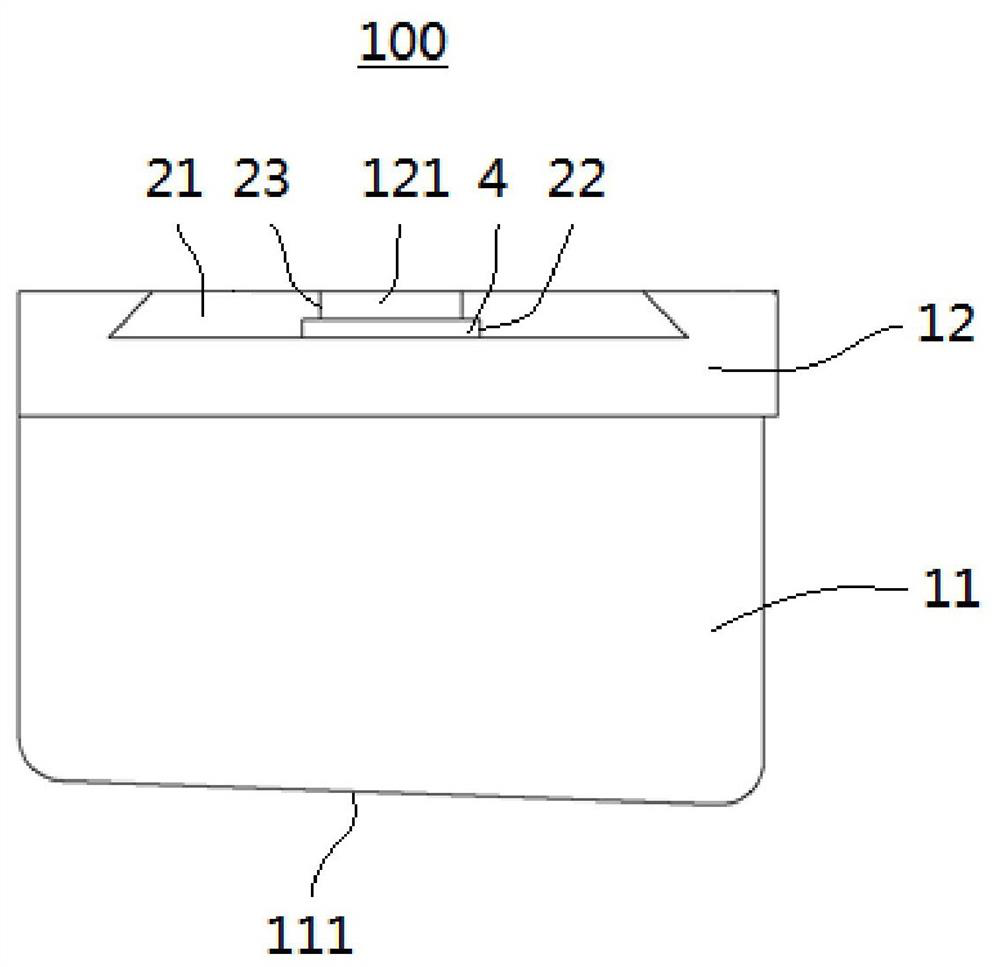

LGP (Light Guide Plate), backlight module and display device

InactiveCN104763979AReduce vibration frictionReduce white point defectsMechanical apparatusLight guides for lighting systemsEngineeringLight guide

The invention discloses an LGP (Light Guide Plate), a backlight module and a display device, and relates to the field of a display technology. The LGP comprises a diaphragm limit part and a fixed part, wherein the diaphragm limit part is arranged on an emergent surface of the LGP and is used for limiting an optical diaphragm, and the fixed part is used for fixing the LGP and a plastic frame. Therefore, the LGP is capable of effectively solving the problems of vibration friction and bad white points between the LGP and the optical diaphragm.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

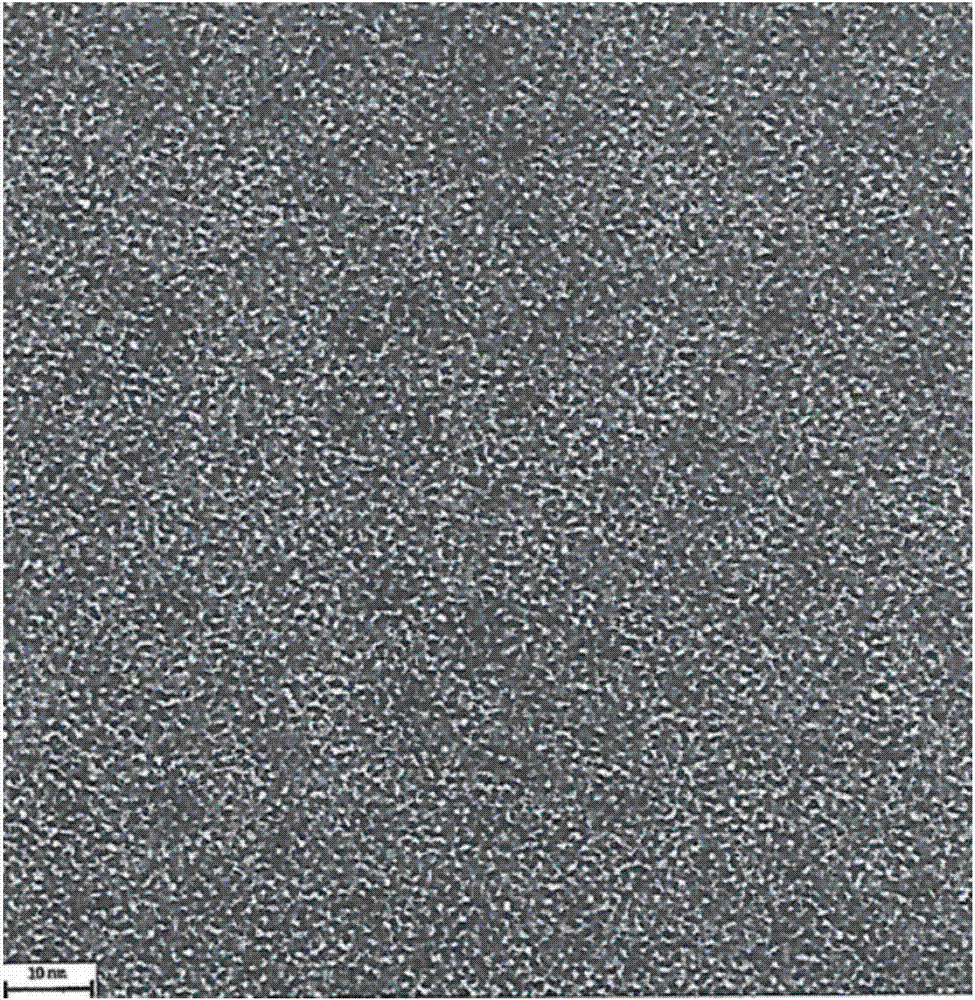

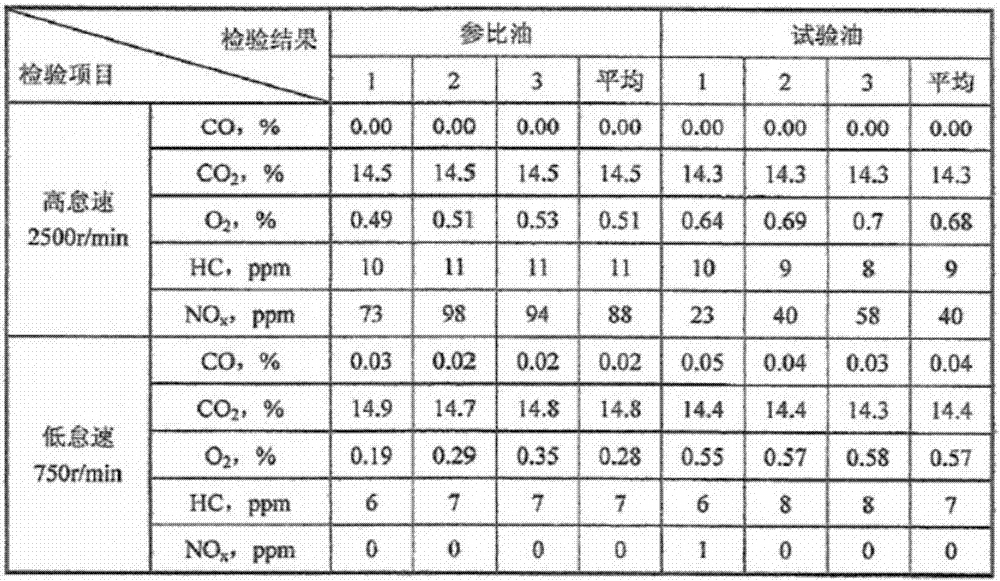

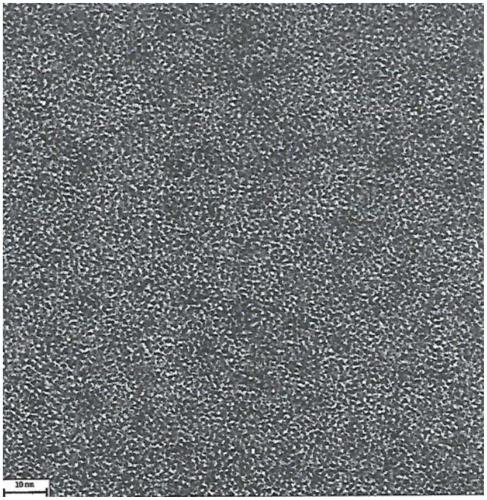

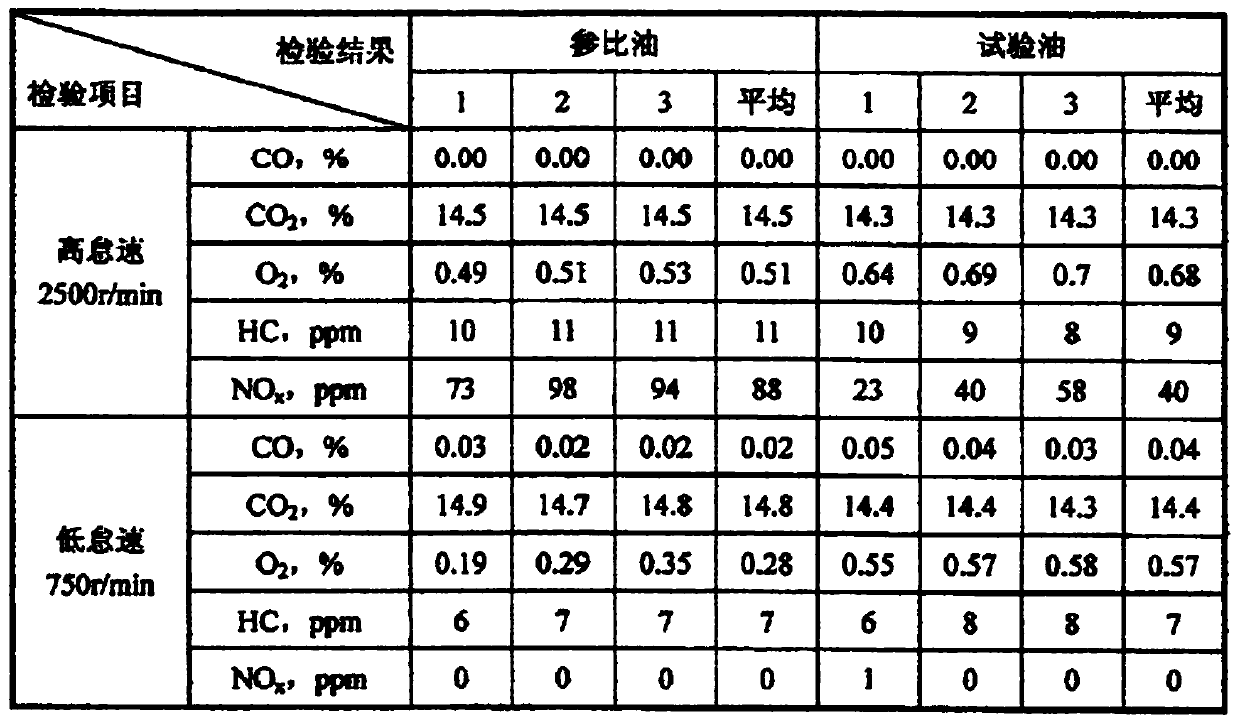

Energy-saving and environment-friendly lubricating oil capable of self-repairing wear for internal combustion engine and preparation method of energy-saving and environment-friendly lubricating oil

ActiveCN107488491AWon't fall offWork effectively for a long timeLubricant compositionExternal combustion engineAntioxidant

The invention discloses energy-saving and environment-friendly lubricating oil capable of self-repairing wear for an internal combustion engine and a preparation method of the energy-saving and environment-friendly lubricating oil, and belongs to the field of lubricating materials. The energy-saving and environment-friendly lubricating oil is prepared from the following components in percentage by weight: 87 to 90 percent of base oil and 10 to 13 percent of additive, wherein the additive is prepared from the following components in percentage by weight: 1.2 to 2.5 percent of a calcium-containing clearing agent, 1.3 to 2 percent of a dispersing agent, 0.5 to 1.4 percent of an anti-wear agent, 1.5 to 2.5 percent of an antioxidant, 0.5 to 0.8 percent of a corrosion inhibitor, 1.5 to 2 percent of a viscosity index improver and 1.1 to 3.5 percent of a friction improver; the friction improver is polytetrafluoroethylen high-molecular compound ultramicro nano-powder and the particle size of the powder is 2 to 12 nm. According to the energy-saving and environment-friendly lubricating oil disclosed by the invention, the problem that existing lubricating oil for the internal combustion engine cannot repair friction and wear of internal parts in the engine is solved; in addition, the design tolerance gap can be automatically compensated and non-disassembly in-situ repair can be carried out, thereby improving the sealing property of a cylinder, a piston and other parts; in addition, a compression ratio and an air-fuel ratio of the engine are improved, fuel oil is combusted more sufficiently, the discharge of exhaust pollutants is reduced and the frictional resistance is reduced.

Owner:安徽游能润滑新技术有限公司

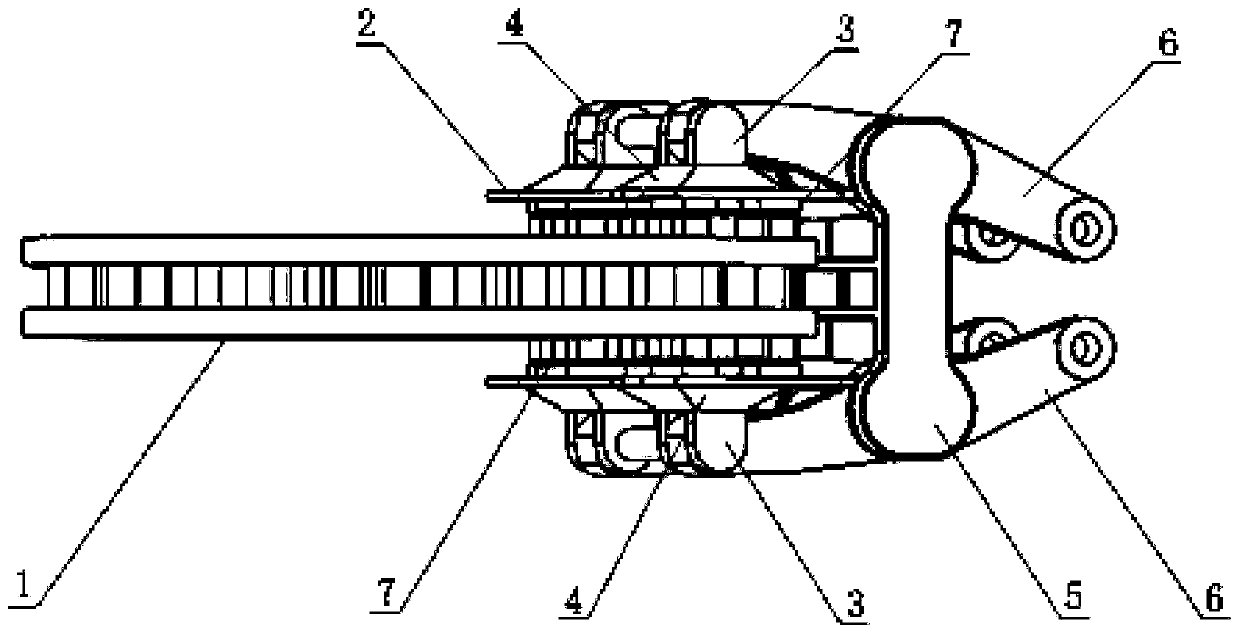

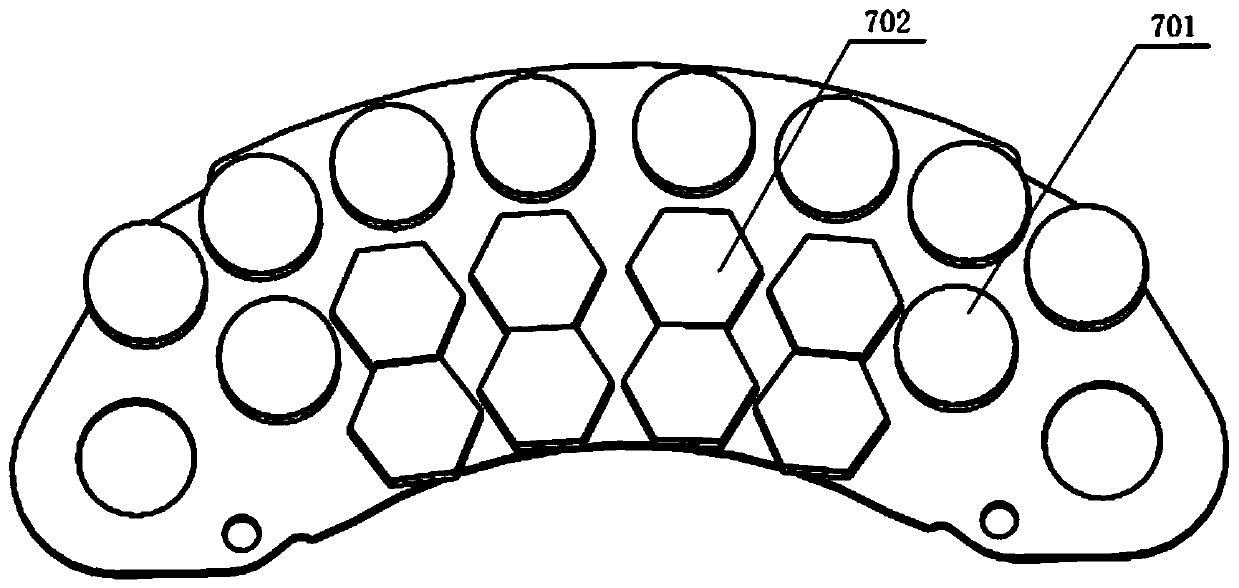

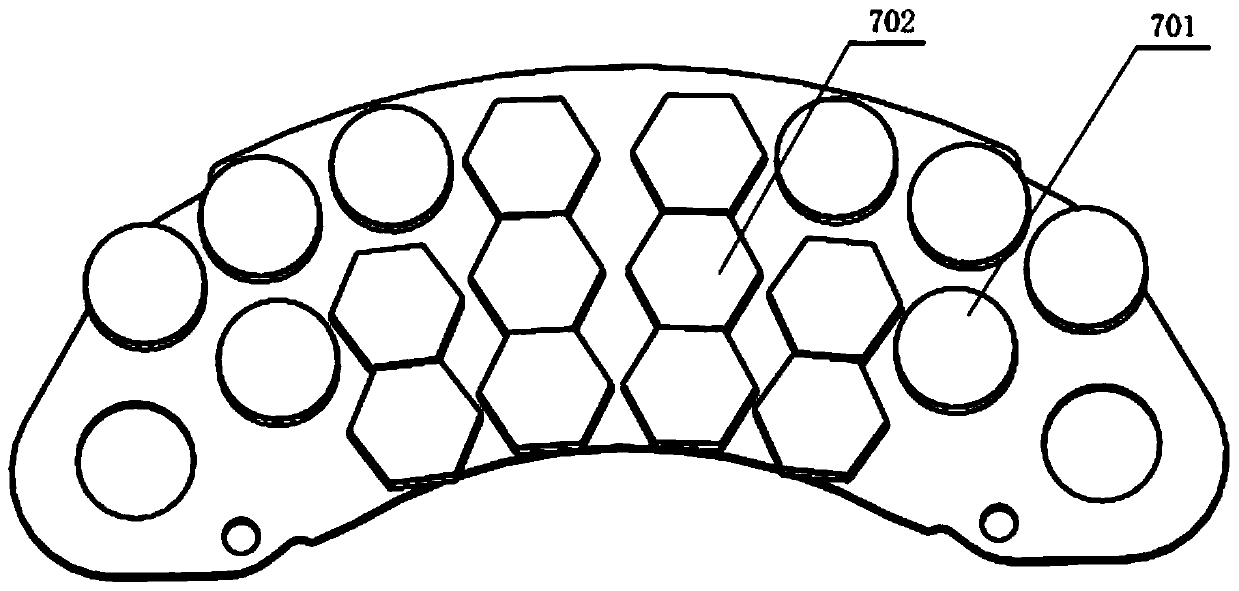

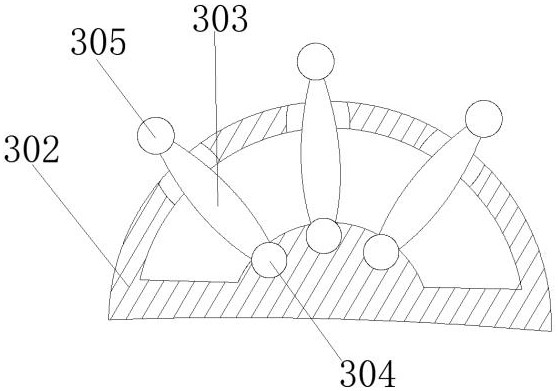

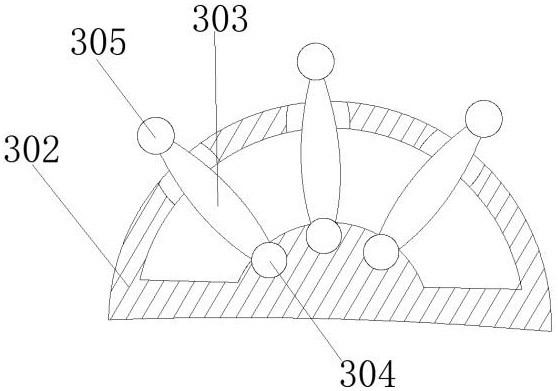

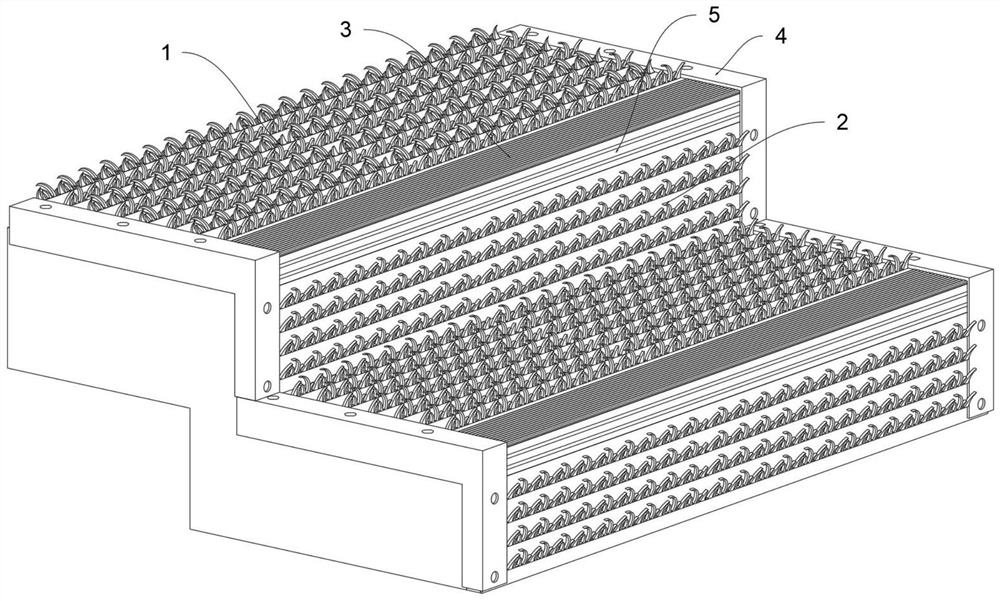

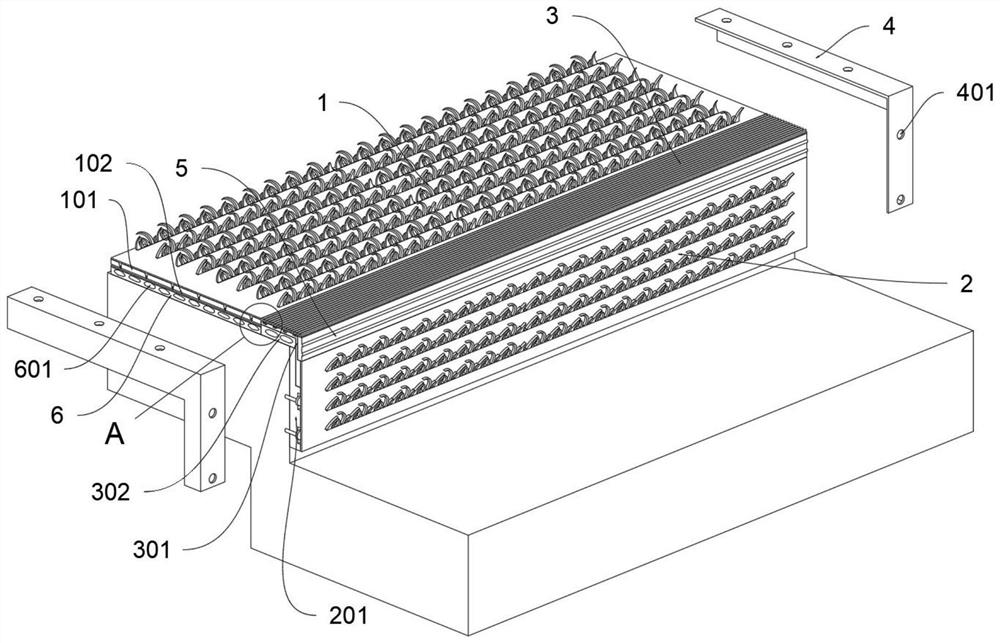

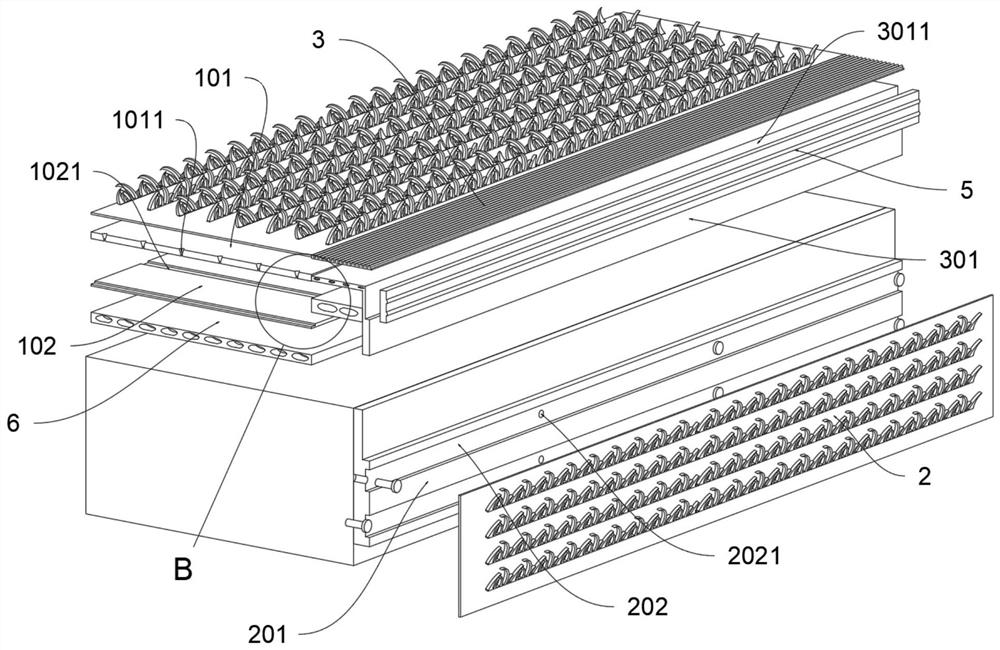

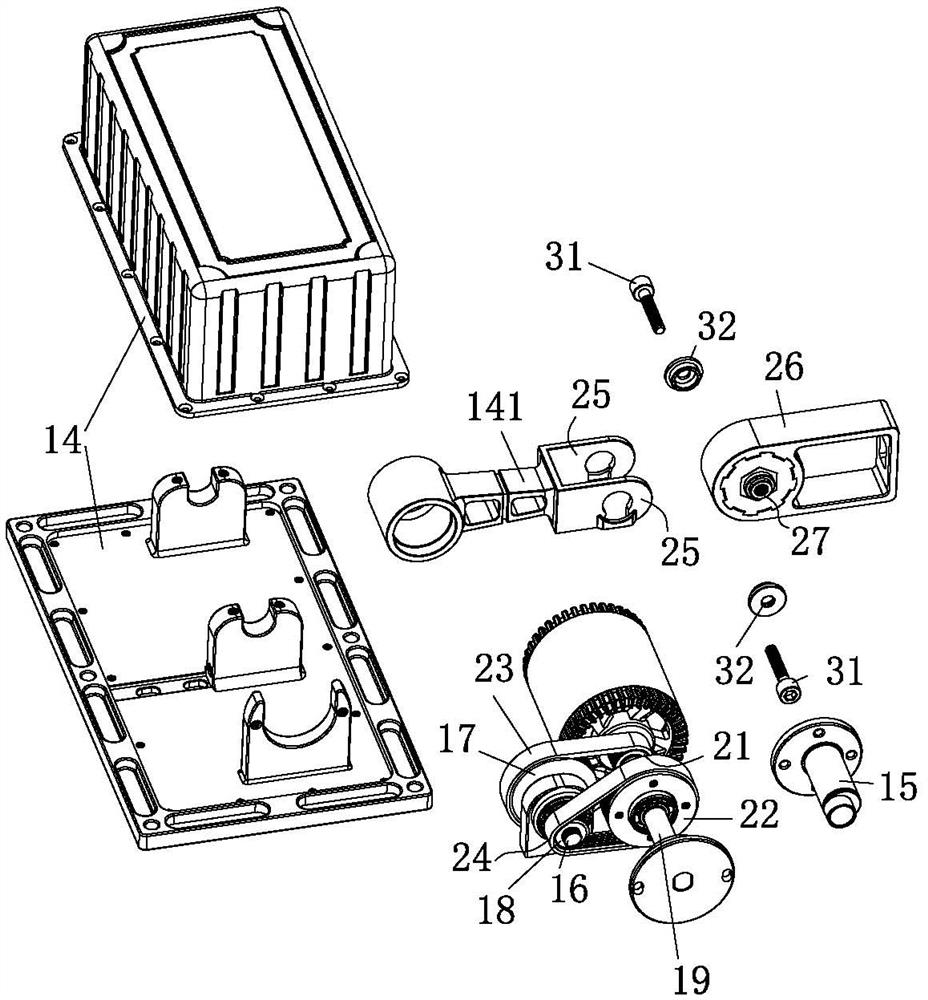

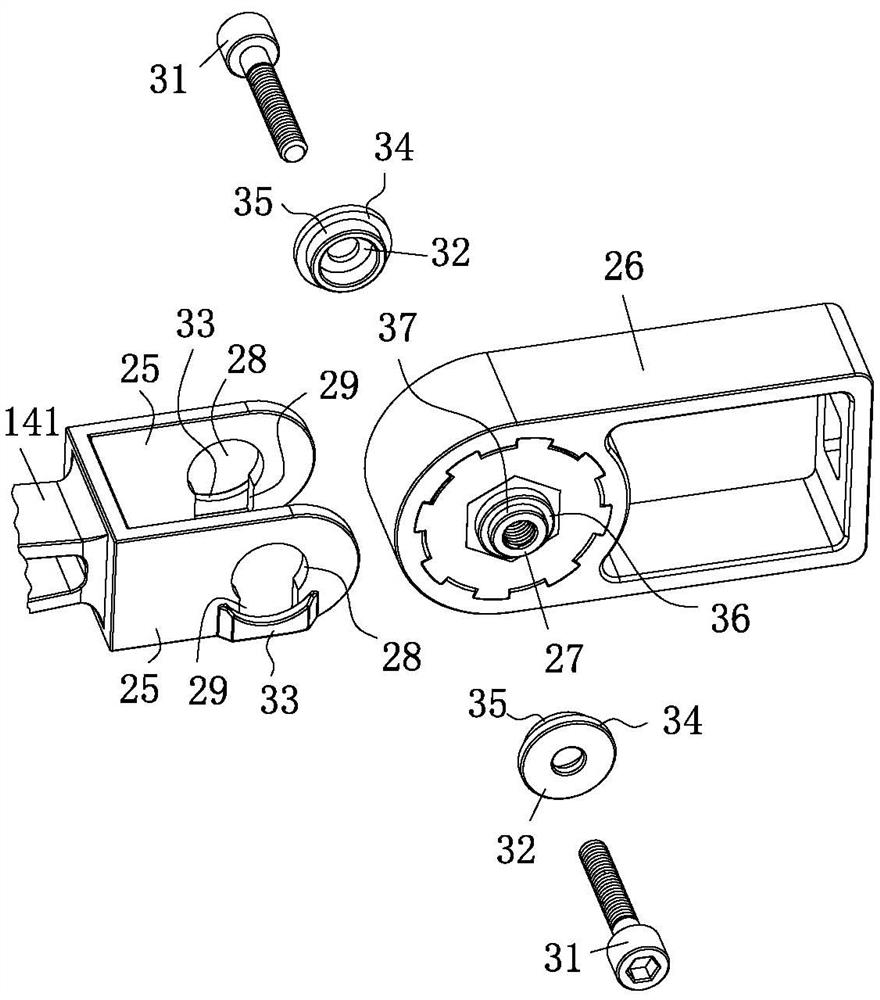

High-speed train brake pad for optimizing friction particle combination and installation modes

ActiveCN111396474AEnsure braking reliability and safetyReduce noise pollutionNoise/vibration controlFriction liningPhysicsHeat distribution

The invention belongs to the technical field of friction braking, and particularly relates to a high-speed train brake pad for optimizing friction particle combination and installation modes. The problems of simplex shape of friction particles, eccentric wear, high braking noise and non-uniform heat distribution on a brake interface of an existing brake pad are solved. The technical scheme is as follows: the idea of combining friction particles of different shapes and materials is put forward, and the advantages of the friction particles of various shapes and materials are comprehensively utilized by flexibly arranging the friction particles of various shapes and materials in different areas; a fixing mode of the friction particles is optimized; and an anti-rotation mode of the friction particles is optimized, and a guide shaft and a mounting hole are optimized to be cylinders with a non-circular section shape. The advantages of the friction particles of different shapes and materialsare organically combined, and the reliability, safety and comfortableness of a brake system are improved.

Owner:SOUTHWEST JIAOTONG UNIV

Diaphragm and speaker

ActiveCN108900955BSmooth vibrationReduce vibration frictionNon-planar diaphragms/conesWave shapeEngineering

Owner:GOERTEK INC

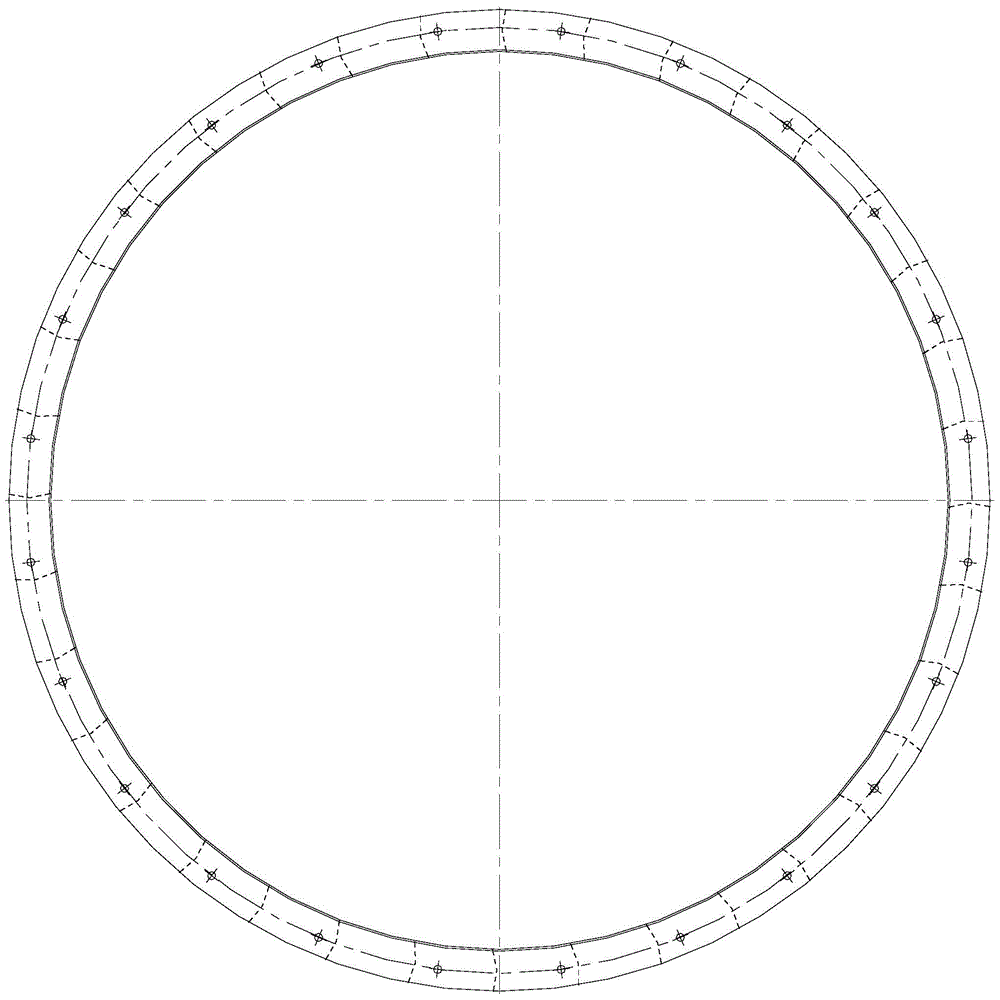

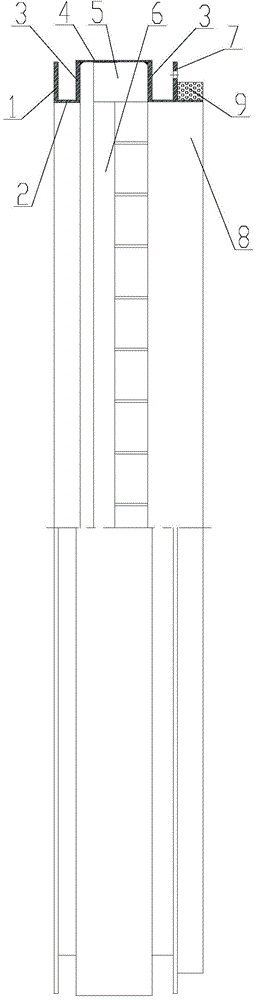

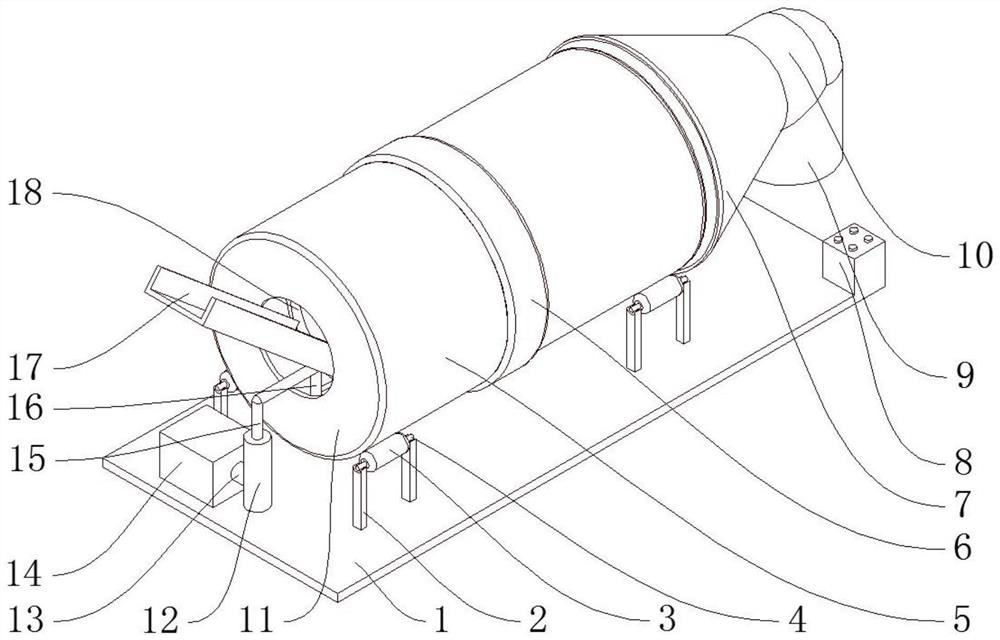

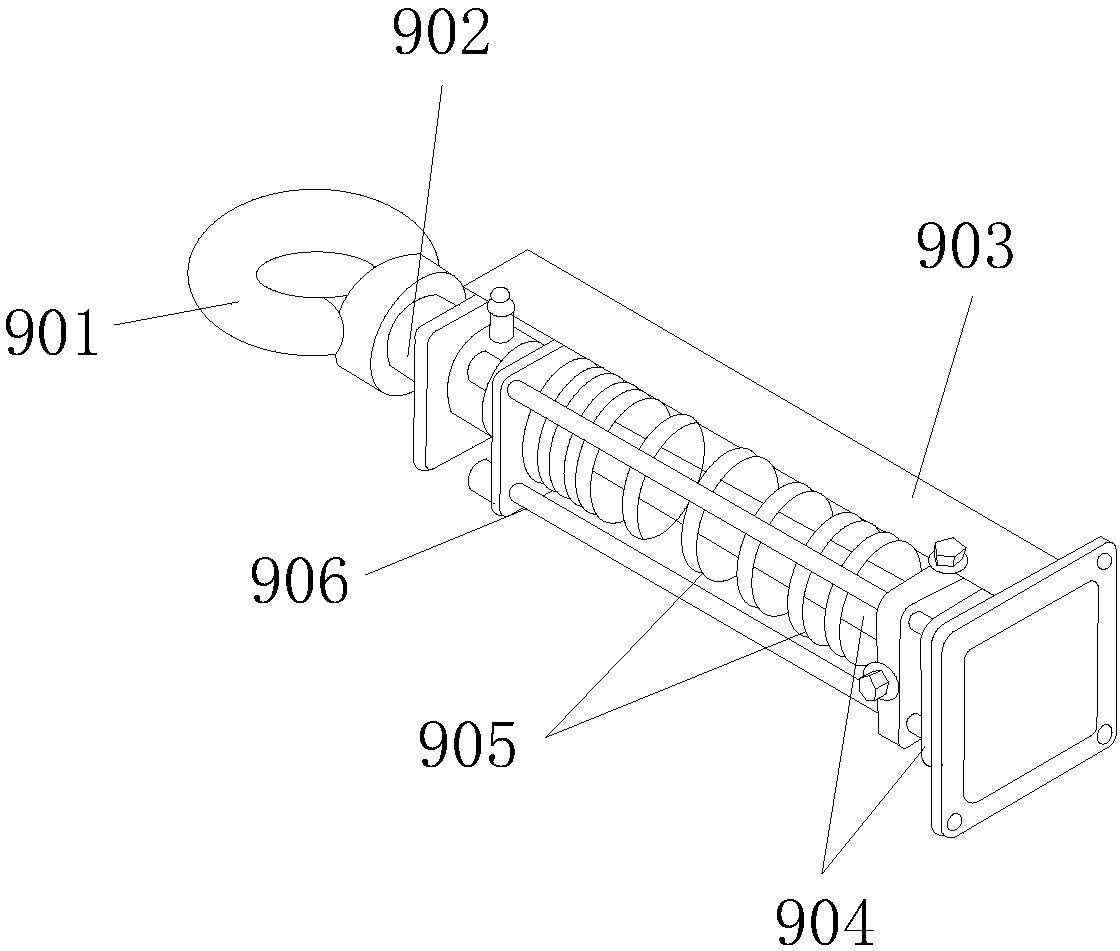

Anti-surge ring for axial flow fan

InactiveCN104088820ASolve technical problems prone to surge phenomenonAvoid surge phenomenonPump componentsPumpsEngineeringFlange

The invention belongs to the technical field of metro fan devices, and particularly relates to an anti-surge ring for an axial flow fan. The anti-surge ring aims to prevent the surge phenomenon occurring in the axial flow fan. According to the technical scheme, a connecting flange, a small cylinder, two surge flanges, an outer ring, a plurality of spoilers, an inner flow guide ring, a quick connector flange and a quick connector. The outer edges of the surge flanges are connected with the two ends of the outer ring to form an anti-surge ring cavity, the right end of the small cylinder is connected with the inner edge of the surge flange on the left side, the left end of the small cylinder is connected with the inner edge of the connecting flange, the left end of the quick connector is connected with the inner edge of the surge flange on the right side, the quick connector flange is arranged in the middle of the outer surface of the quick connector, and the inner flow guide ring is arranged on the left edges of the spoilers. The anti-surge ring for the axial flow fan has the advantages of being convenient and fast to install and reducing vibration friction among all components.

Owner:SHANXI ANRUI FAN ELECTRIC

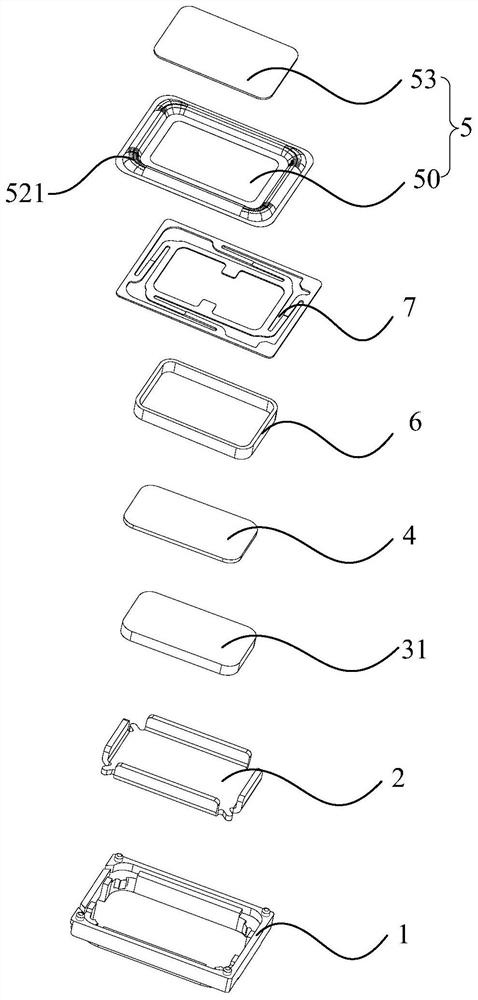

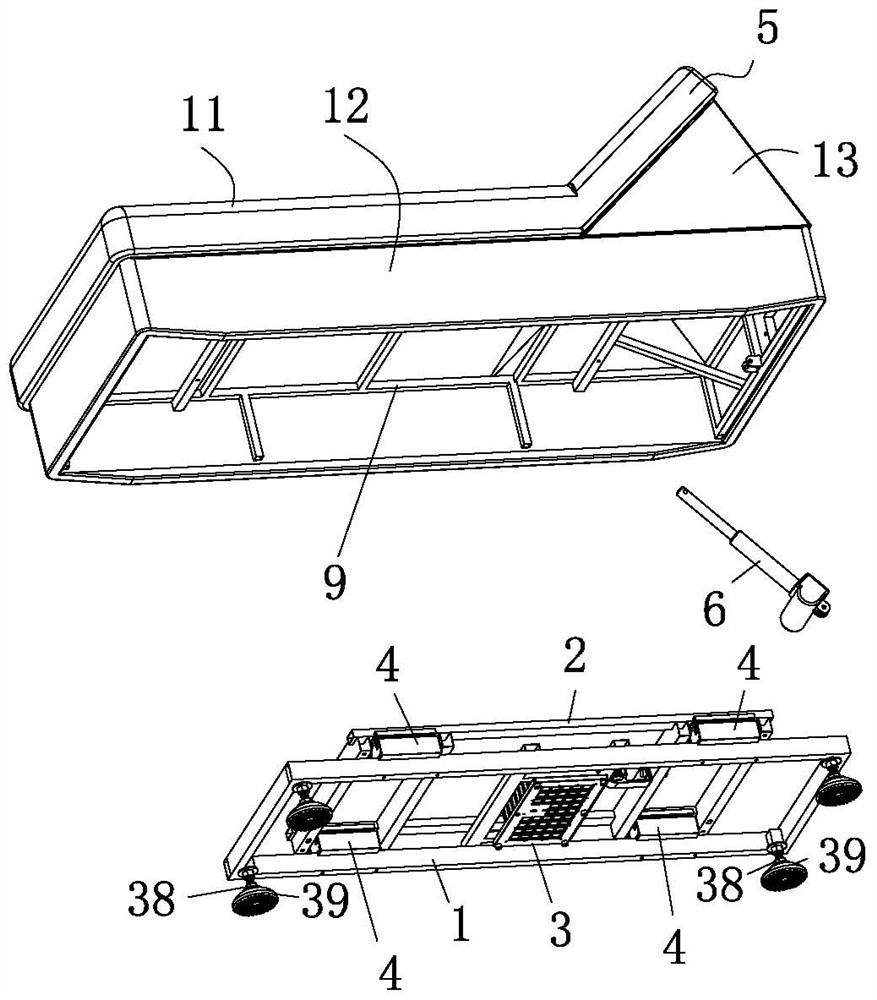

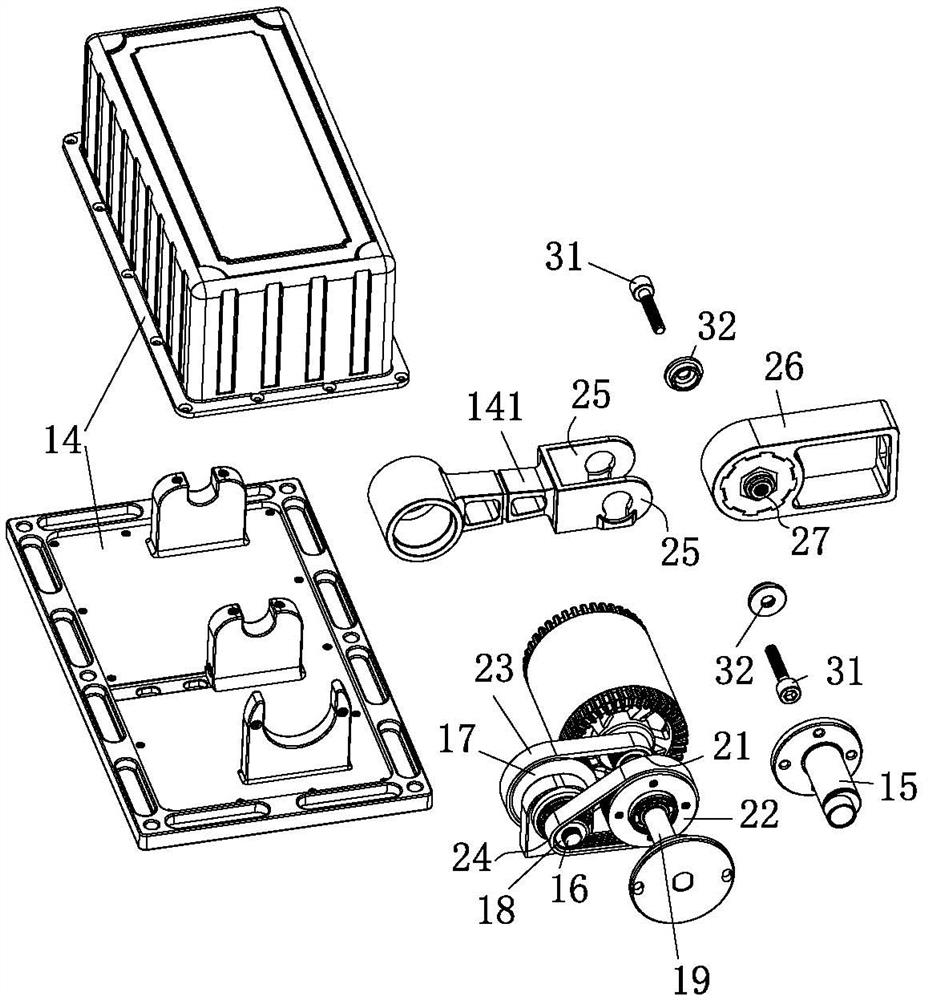

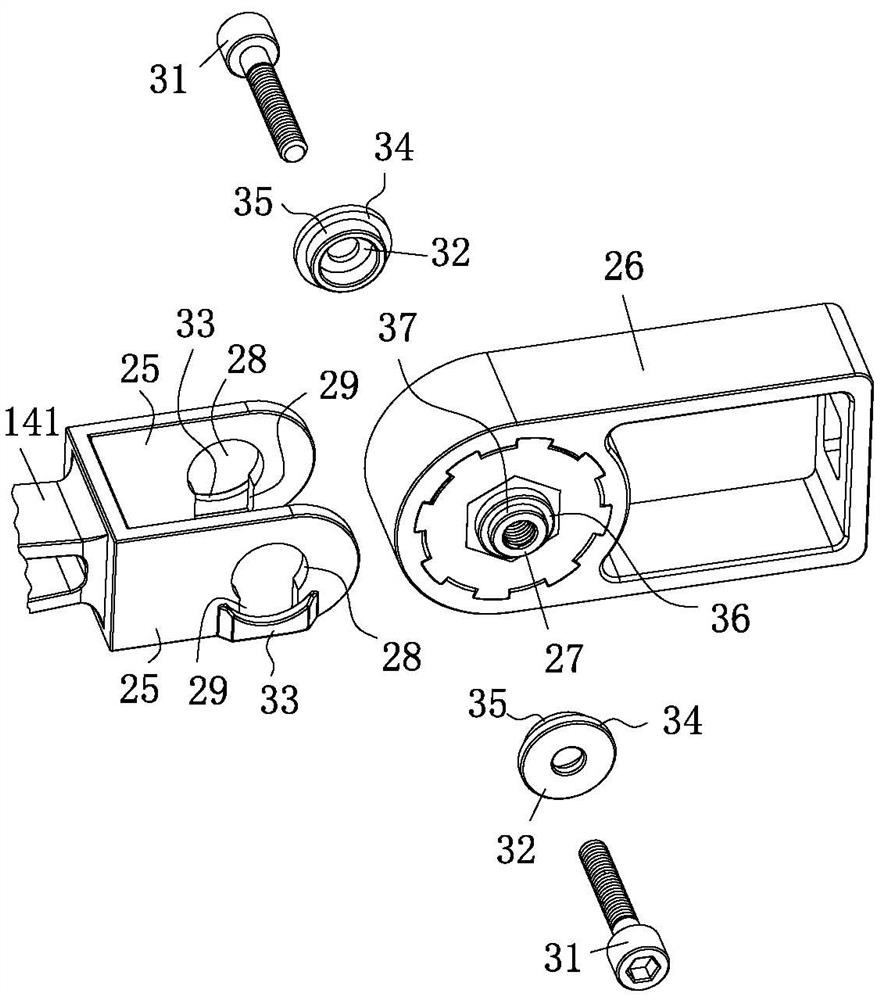

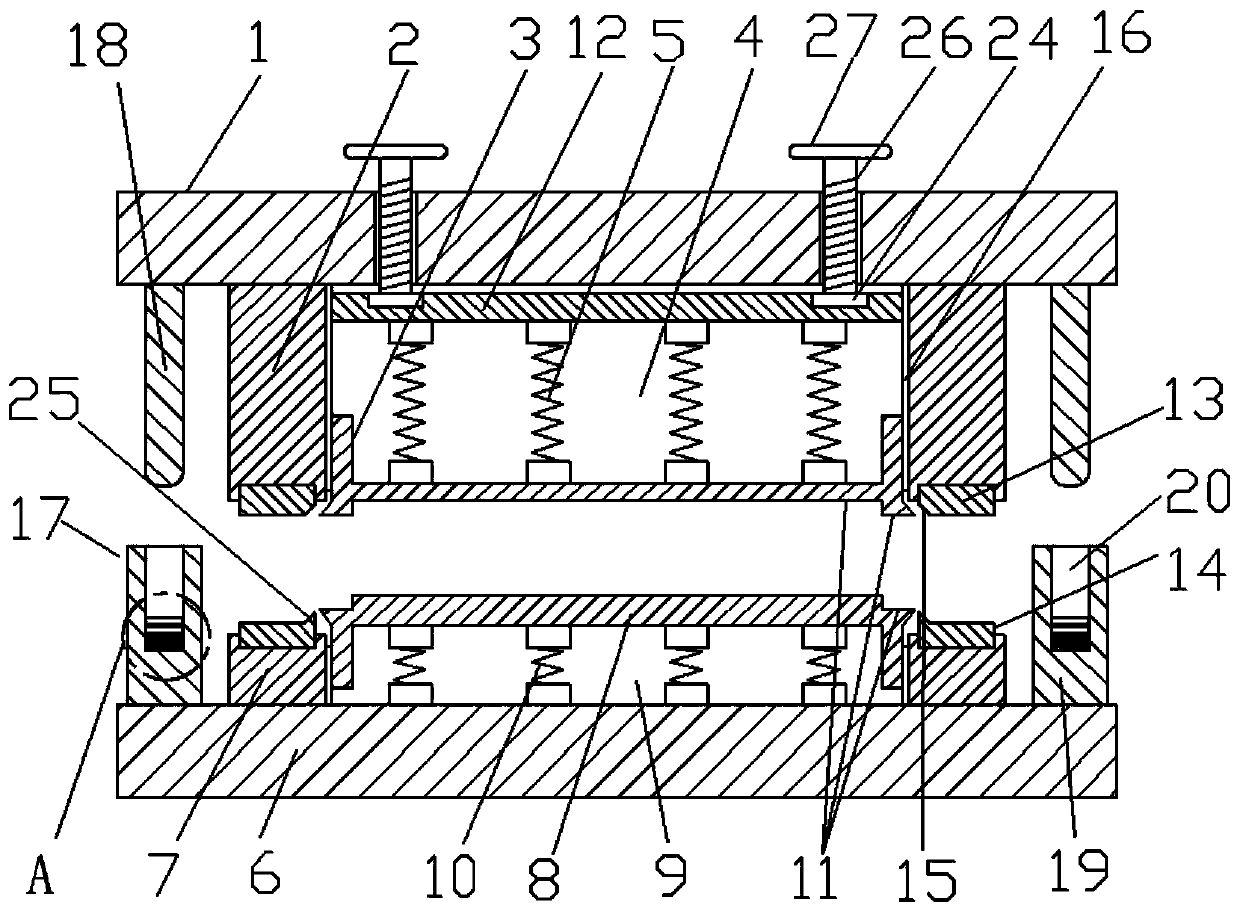

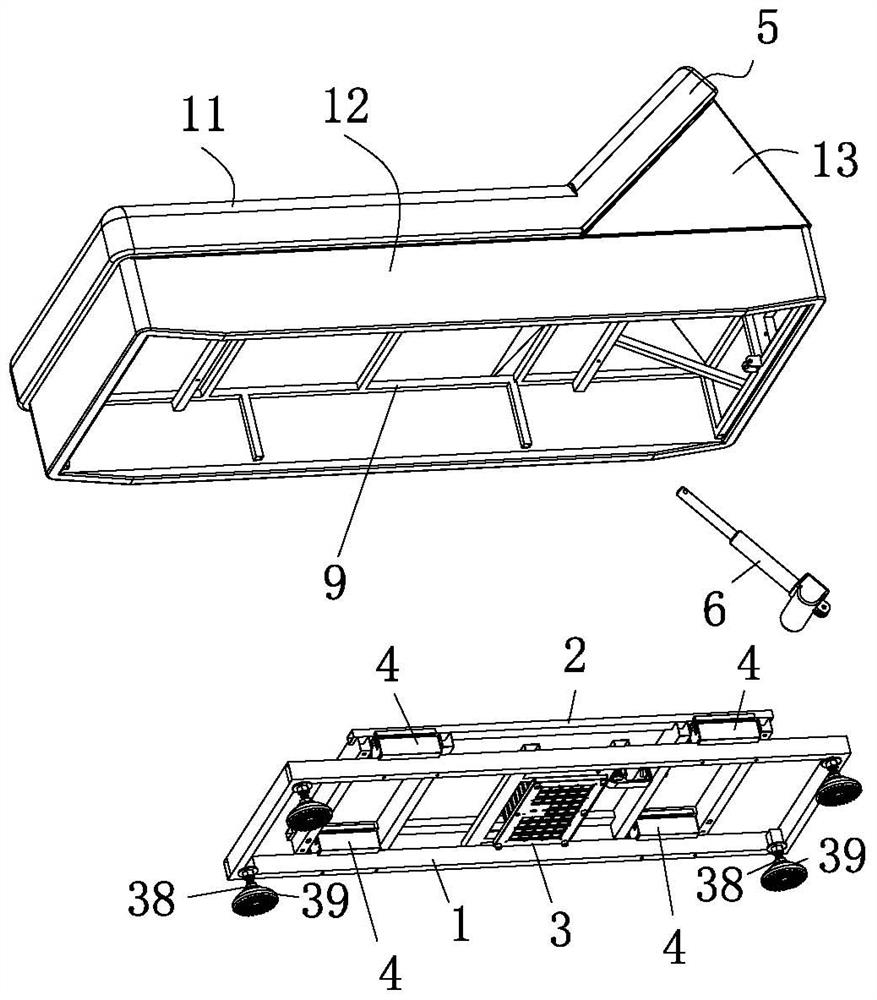

A multifunctional low noise vibration structure

ActiveCN112603798BReduce frictionReduce vibration frictionChiropractic devicesSofasLow noiseClassical mechanics

The invention relates to the technical field of vibration structures, and in particular discloses a multifunctional low-noise vibration structure, comprising a fixed frame, a moving frame, and a first driving member. The first driving member drives the moving frame to move back and forth relative to the fixed frame; the second driving member drives The lifting frame moves relative to the movable frame; the rolling guide rail unit includes a fixed seat, a movable seat, and a roller member rollingly arranged between the fixed seat and the movable seat, the fixed seat is arranged on the fixed frame, and the movable frame is arranged on the movable seat; the fixed seat It has a first groove body, the moving base is provided with a second groove body, and the two ends of the roller part are respectively accommodated in the two groove bodies; the user can place the head or legs on the lifting frame after the second driving part moves On; with the help of the structure of the roller parts of the rolling guide unit, the friction between the fixed frame and the moving frame is reduced, the wear between the two is delayed, the vibration friction of the vibration structure is reduced, the service life is prolonged, and the operation of the vibration structure is improved. stability.

Owner:GUANGDONG NUOJIANG HEATH TECH CO LTD

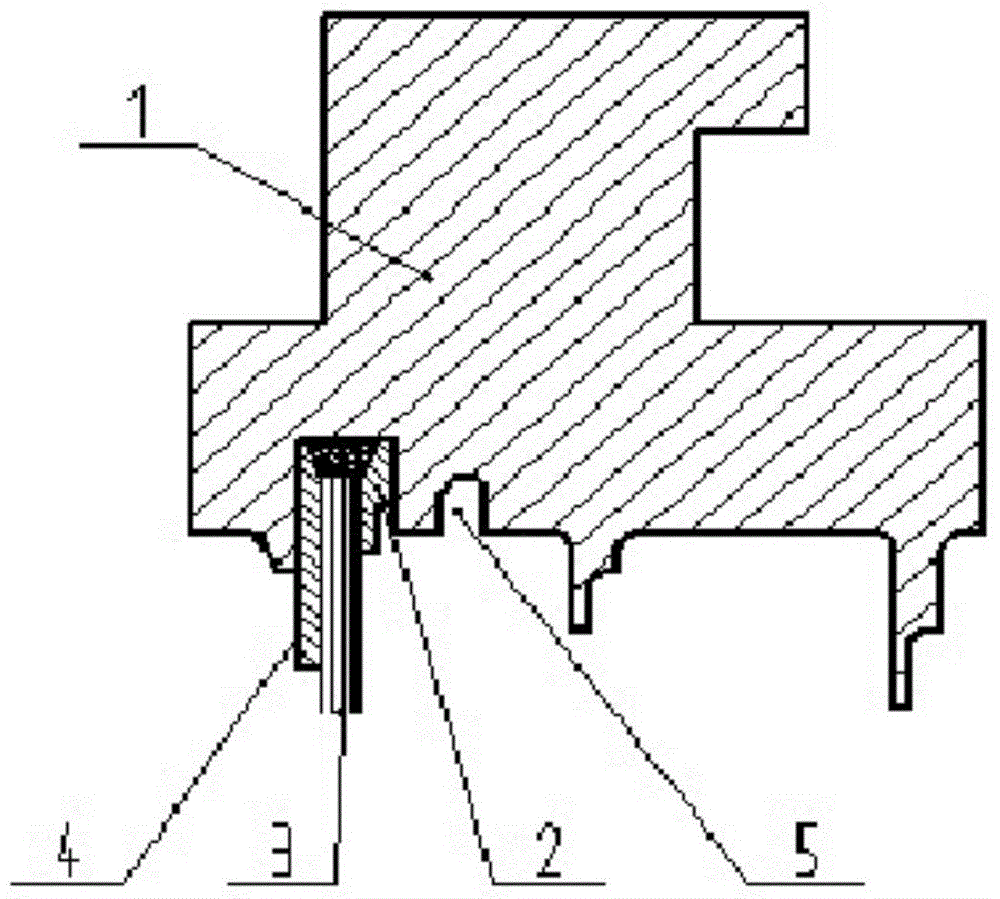

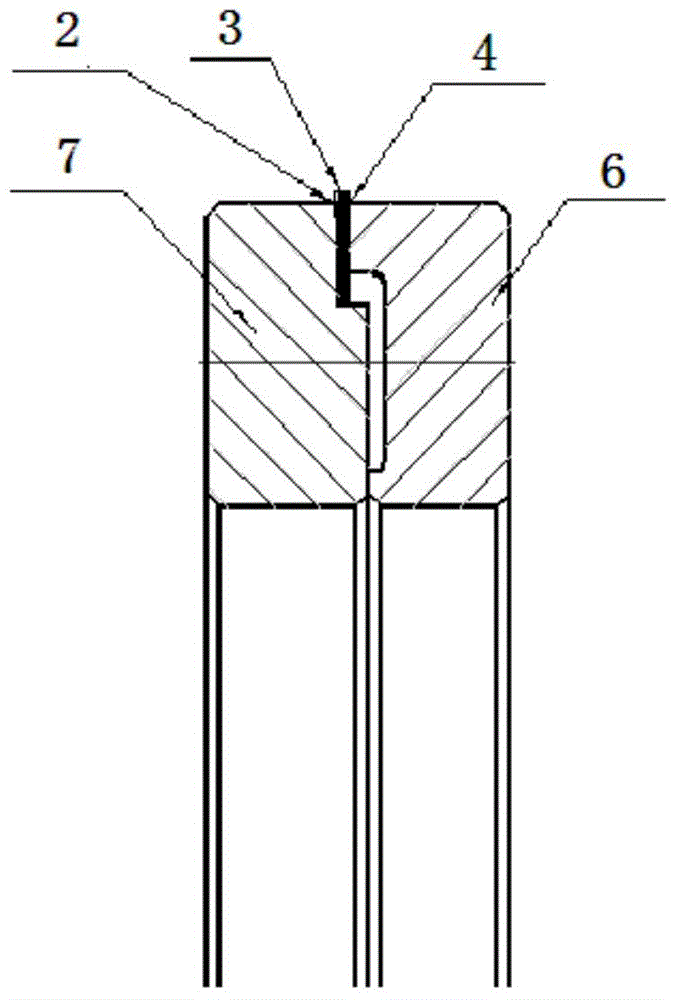

Plate trimming and forming mould

InactiveCN110899509AReduce vibration frictionLow costShaping toolsUltimate tensile strengthFriction force

The invention discloses a plate trimming and forming mould and belongs to the technical field of moulds. According to the technical scheme, the plate trimming and forming mould is characterized in that flanging forming surfaces are arranged on a material pressing core and a material supporting core separately, meanwhile, cutting blocks are arranged on the edges of the flanging forming surfaces, two processes of flanging and cutting can be completed in the process that an upper mould part moves towards a lower mould part and finally is in contact with the lower mould part, the rebounding forceof the material pressing core can be adjusted by adjusting the position of a movable positioning plate, and adjustment is performed according to different materials and plate thicknesses, so that thevibration strength during stamping is reduced, the vibration friction force generated when an upper mould knife and a lower mould knife are in contact is reduced, and the service life of a cutter is prolonged. According to the plate trimming and forming mould, the number of workpiece moulds is reduced, the cost of the mould is reduced, the production efficiency is improved, and the mould has the advantages of simple structure and low cost.

Owner:洪明祈

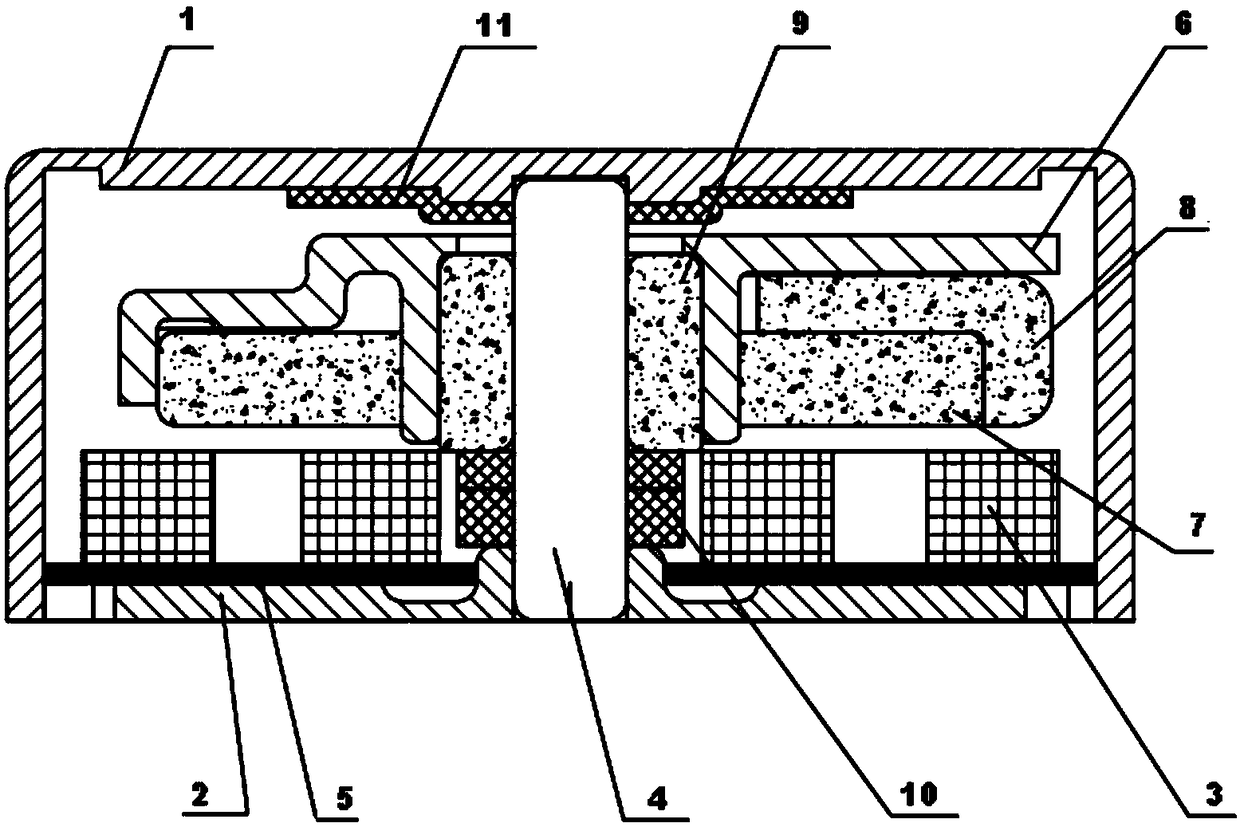

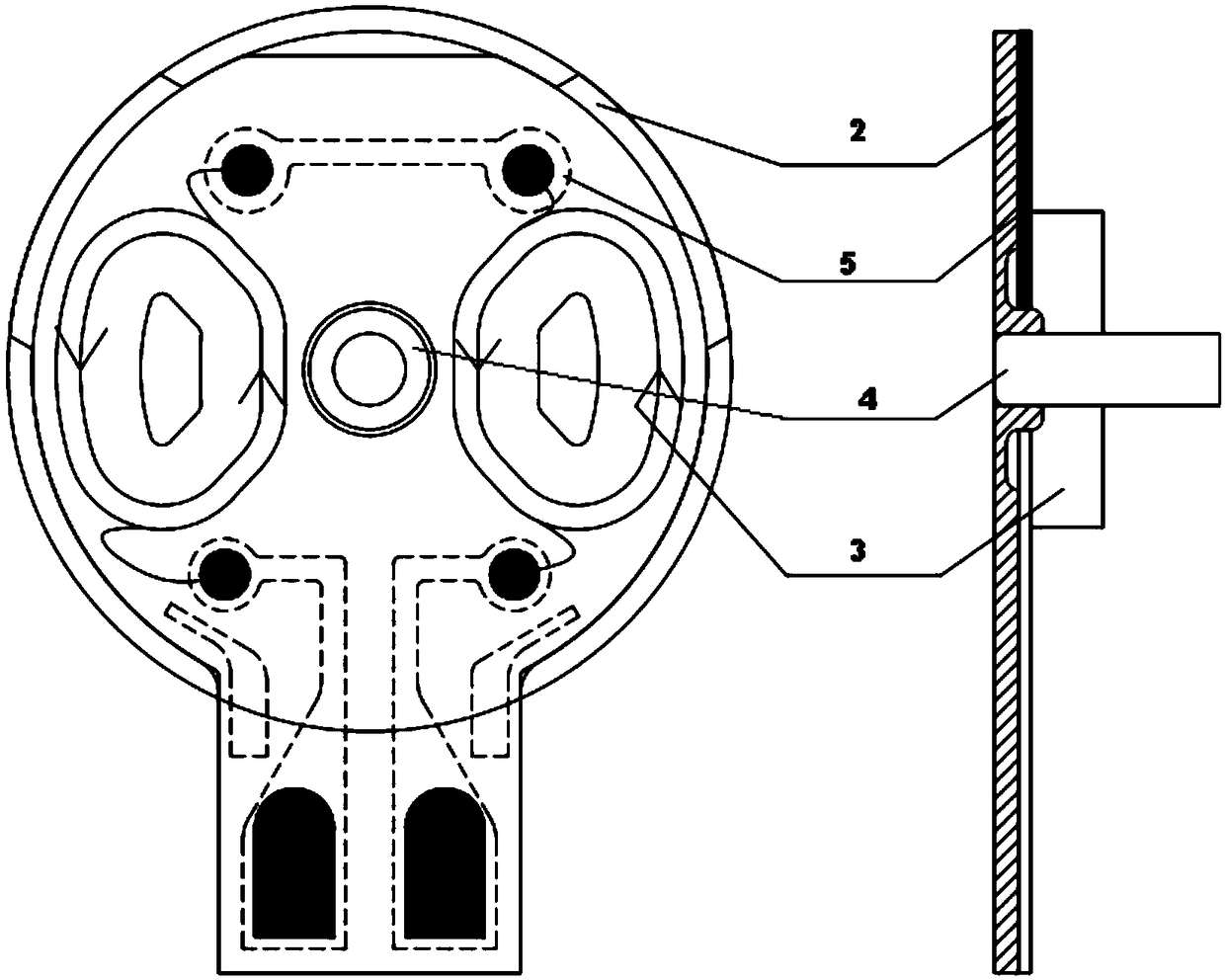

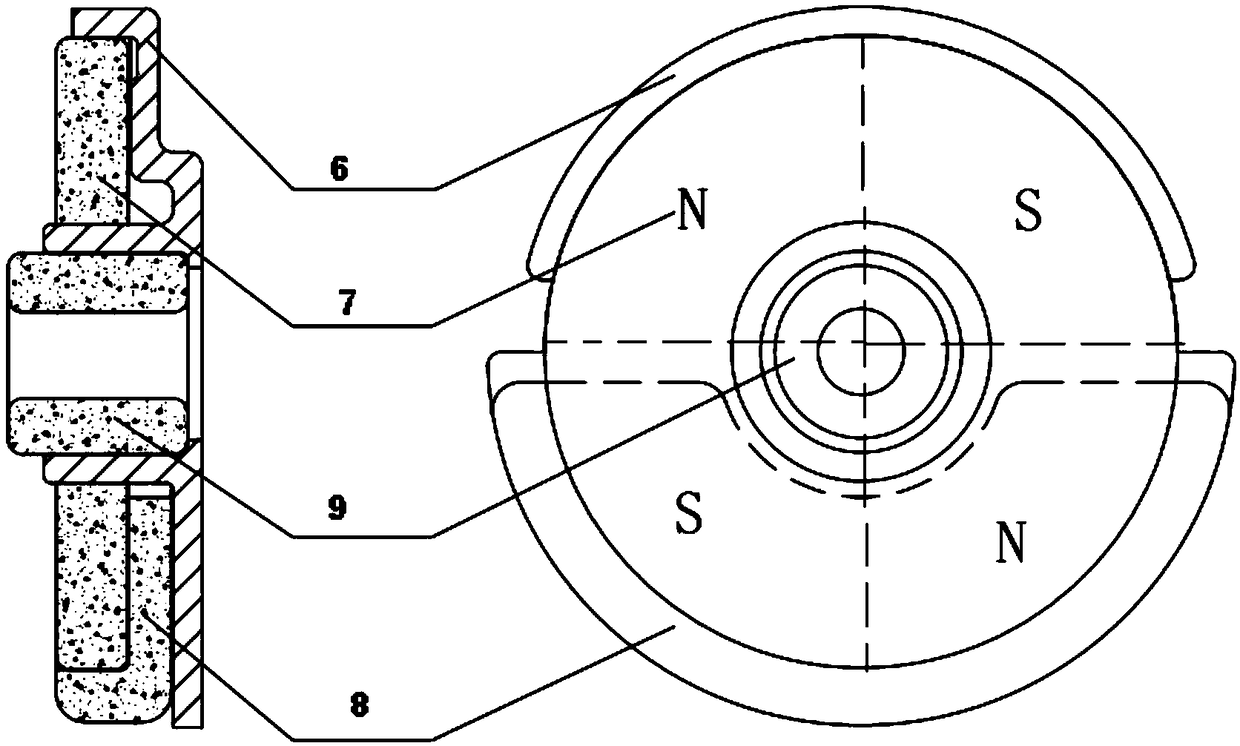

Novel permanent magnet alternating current flat vibration motor and use method thereof

ActiveCN109038939AAchieve the purpose of vibratingSimple structureMechanical energy handlingSupports/enclosures/casingsEngineeringAlternating current

The invention discloses a use method of a novel permanent magnet alternating current flat vibration motor, comprising a cylindrical shell with an opening at a lower end, and a rotor and a stator arranged inside the shell; the stator comprises a chassis arranged on the lower part of the shell, two coils arranged on the chassis, a rotating shaft arranged on the chassis and connected with the chassis, and a plurality of FPC wires arranged on the chassis. The rotor comprises a bracket arranged on a rotating shaft, magnet steel arranged on the bracket and connected with the bracket, an eccentric hammer arranged on one side of the bracket and connected with the bracket, and an oil bearing arranged on the rotating shaft. The two coils are electrically connected to the corresponding FPC wires. Theinvention has the characteristics of effectively prolonging the service life of the motor, reducing the noise and reducing the production cost.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

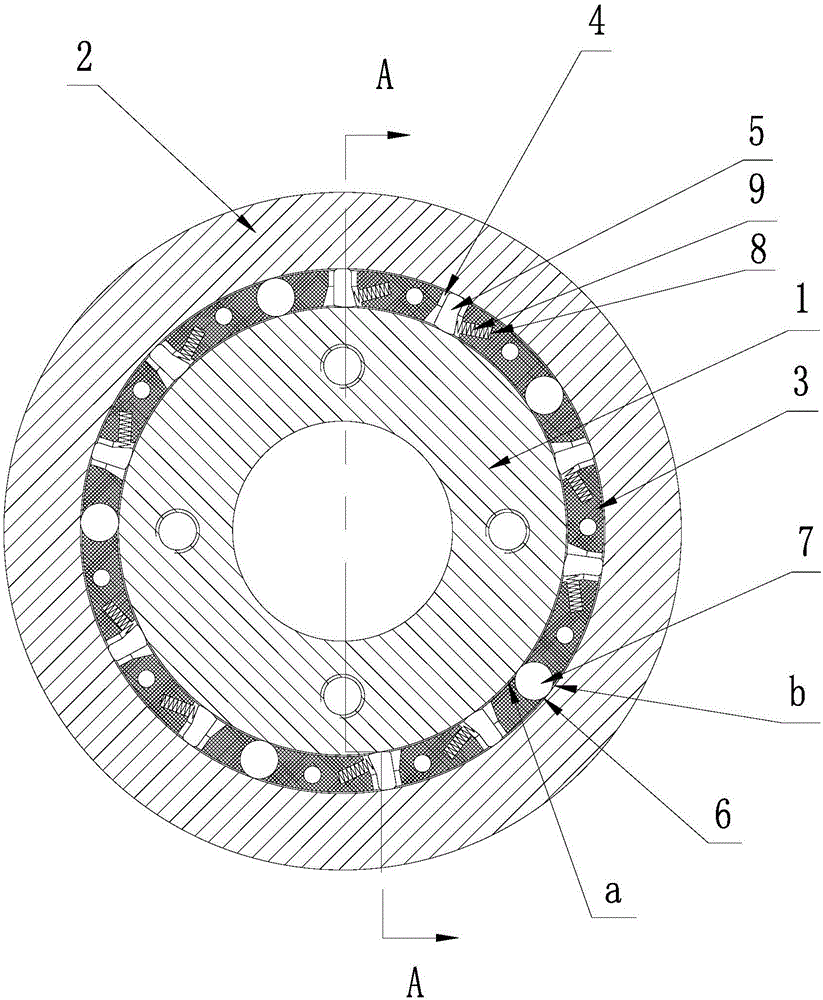

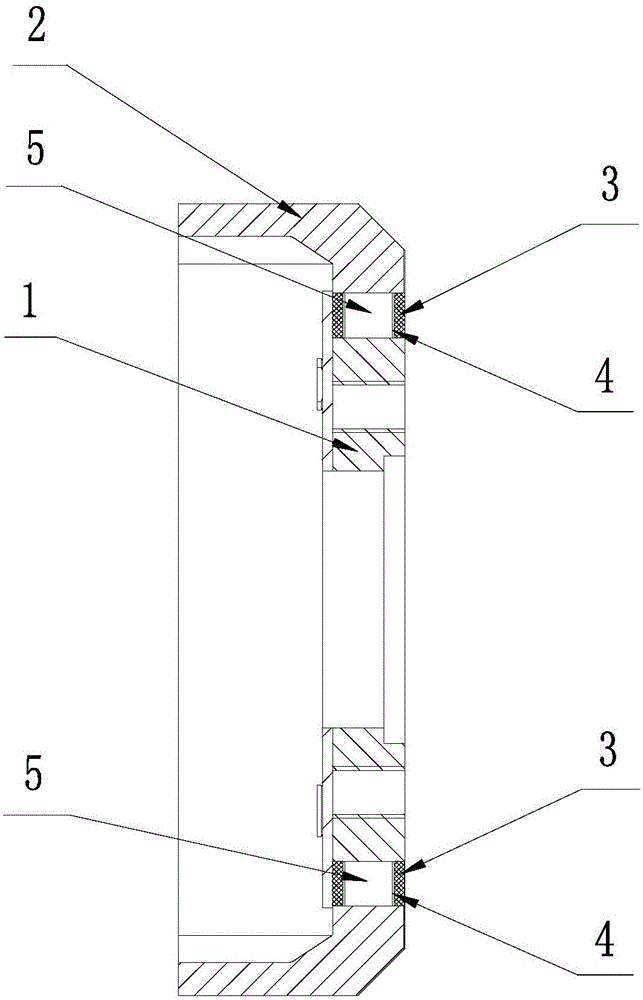

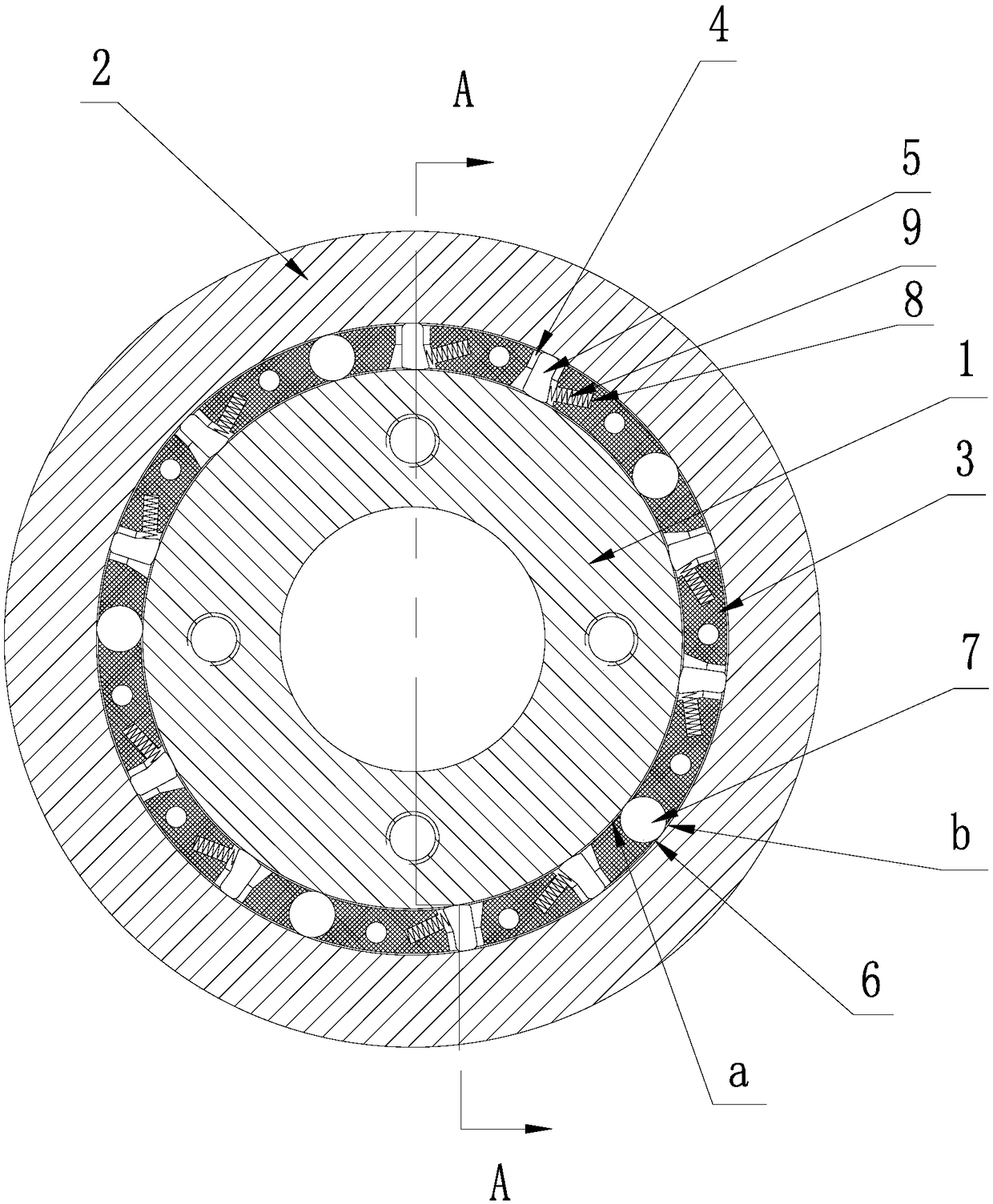

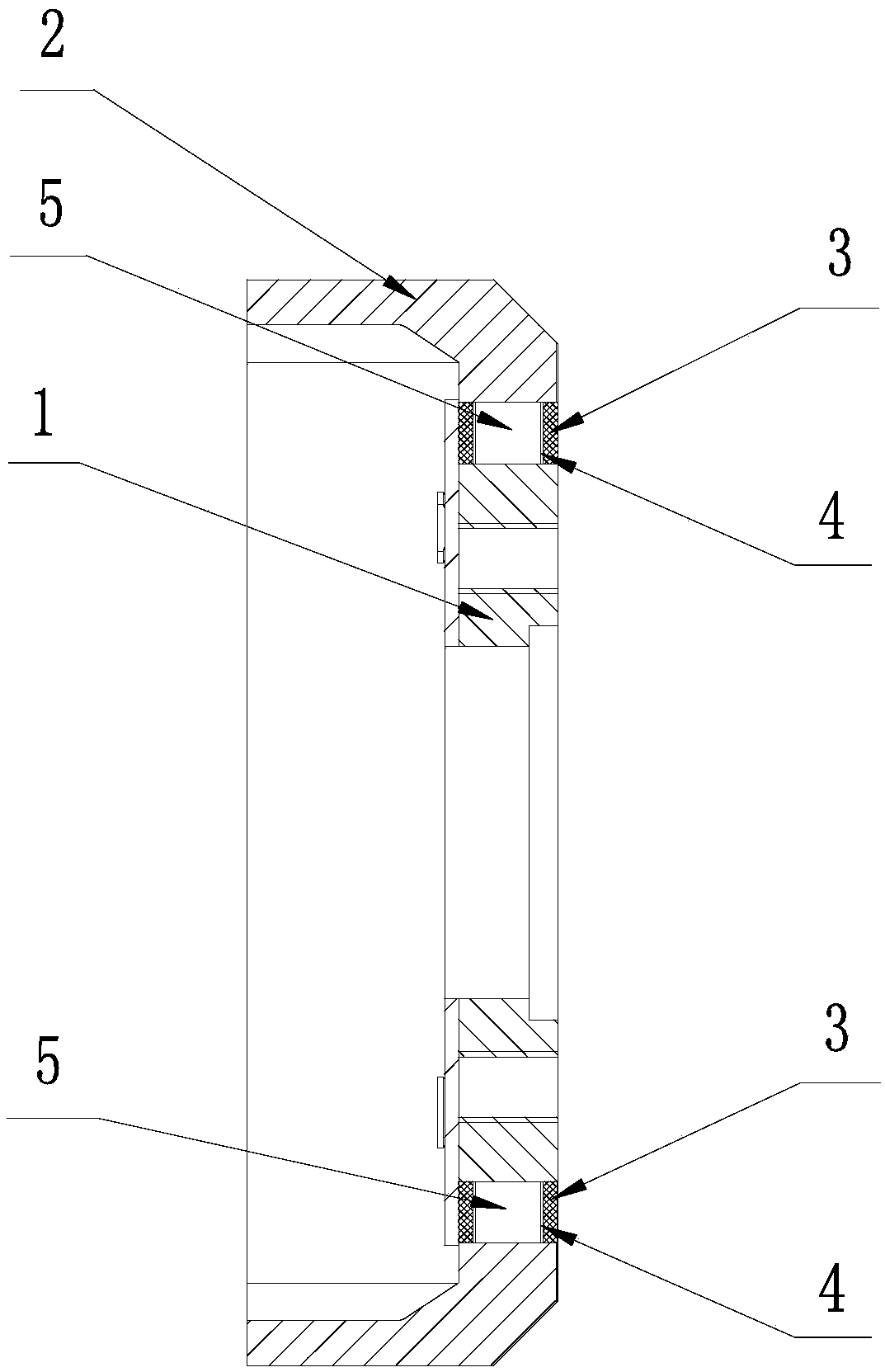

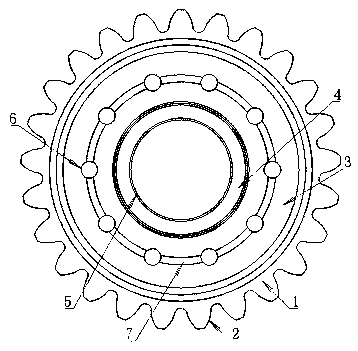

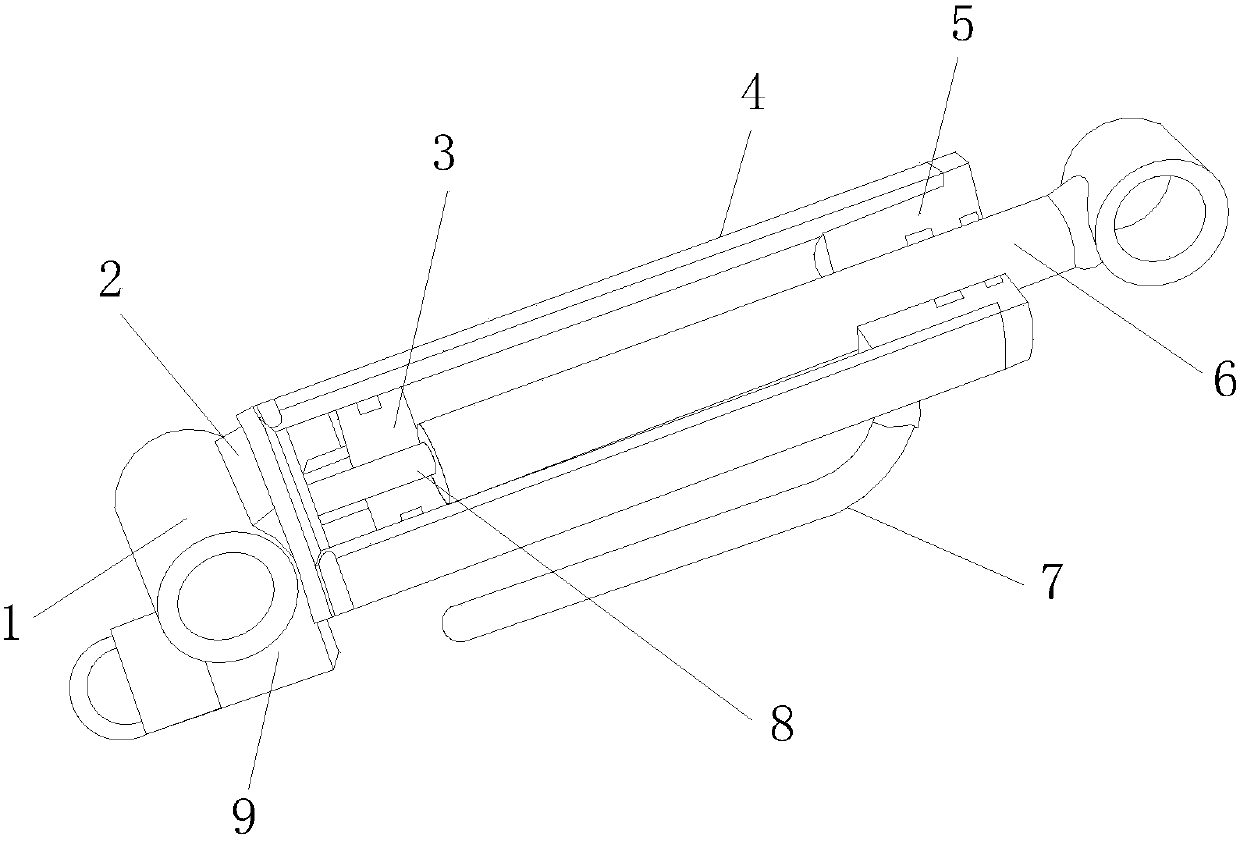

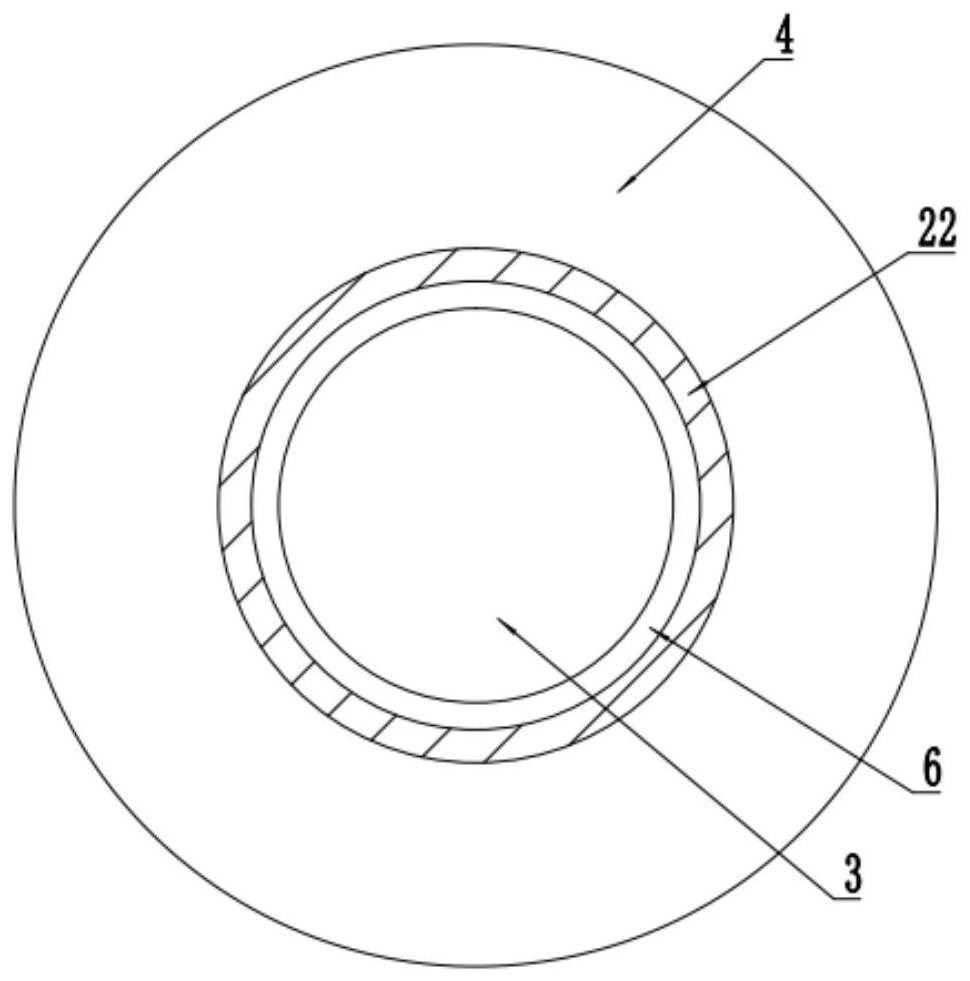

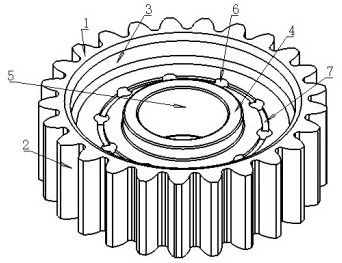

High-stability overrun clutch of electric bicycle

The invention discloses a high-stability overrun clutch of an electric bicycle. The high-stability overrun clutch of the electric bicycle comprises an inner ring, an outer ring and a retaining frame arranged between the inner ring and the outer ring. A plurality of operation grooves are formed in the retaining frame in the circumferential direction. Special-shaped rollers are arranged in the operation grooves. The high-stability overrun clutch of the electric bicycle is characterized in that a plurality of pin roller assembly holes are also formed in the retaining frame in the circumferential direction, pin rollers are embedded in the pin roller assembly holes, and circular arc rolling planes on each pin roller abut against the outer surface of the inner ring and the inner surface of the outer ring correspondingly through opening protrusions arranged on the two side walls of the corresponding pin roller assembly hole. Due to the fact that the pin rollers are arranged on the retaining frame between the inner ring and the outer ring, it is ensured that the inner ring and the outer ring make contact rolling through the pin rollers in the disengagement process of the inner ring and the outer ring, the prior face contact is changed into point contact, the contact area is reduced, friction is reduced, vibration and noise are reduced, and the inner ring and the outer ring are made to rotate more smoothly; and accordingly, it is ensured that a clutch and a whole transmission system of the electric bicycle operate more stably and reliably.

Owner:SUZHOU SHENGYI MOTOR

High Stability Overrunning Clutch for Electric Bicycle

Owner:SUZHOU SHENGYI MOTOR

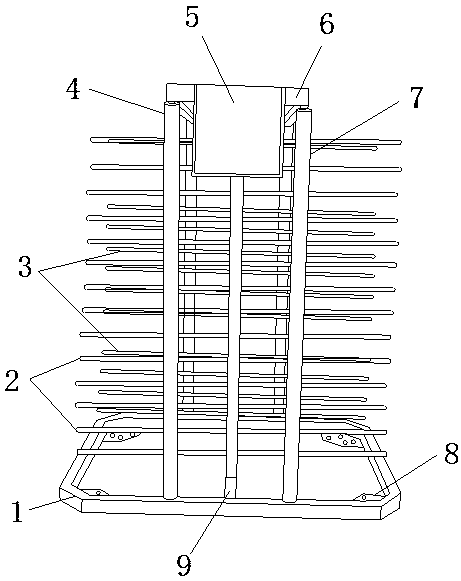

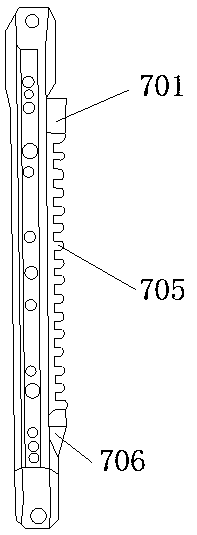

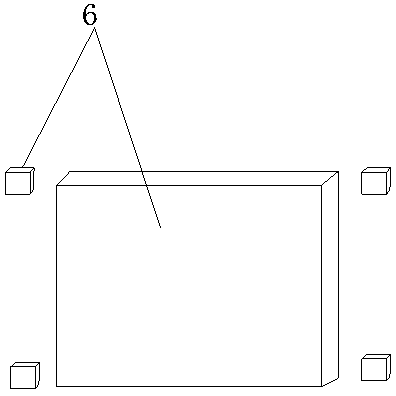

Glass packing assembling frame applicable to industrial production

InactiveCN109775127AImprove fastnessIncrease limit tightnessExternal framesDamagable goods packagingEngineeringInverted u

The invention discloses a glass packing assembling frame applicable to industrial production. The glass packing assembling frame applicable to industrial production structurally comprises a base, first cross bars, second cross bars, supports, a column body, a resisting plate, fixing columns, steel parts and a vertical rod, wherein the supports are of inverted U-shaped frame structures and are correspondingly arranged at the left and right; the sections of the upper end and the lower end of each support are squared and have the same diameter; the vertical rod is arranged between two sides of the supports; the resisting plate is arranged on the surface of the column body in an embedding mounting manner; a side corner of the bottom part of the resisting plate is connected to the correspondingupper end of each support; the lower ends of the supports are vertically mounted on the base; the steel parts are positioned at the outer sides of the lower ends of the supports; first cross bars which are distributed at equal intervals are arranged on the inner walls of the supports. According to the glass packing assembling frame applicable to industrial production, the fixing columns are arranged; arranging grooves are formed at glass intervals; moving parts are clamped into groove ports of a lock; the lock and a fixing plate form an integrated fixed part, so that the fastening performanceof the topmost end of the assembling frame can be effectively improved, and the vibration friction can be reduced.

Owner:宿迁金口工贸有限公司

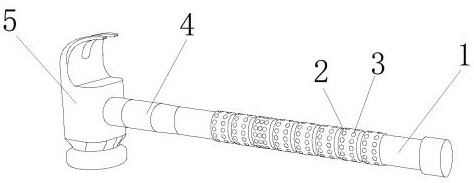

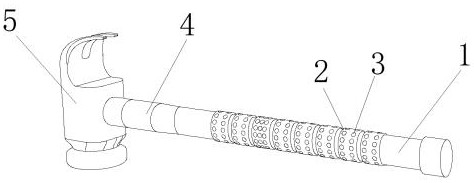

A new type of shock-absorbing high-efficiency hardware tool hammer

ActiveCN113618680BWeakening rangeReduce frequencyHand hammersMetal-working hand toolsComputer hardwareVibration amplitude

The invention discloses a novel high-efficiency hardware tool hammer for shock absorption, and relates to the technical field of hardware. The shock-absorbing new high-efficiency hardware tool hammer includes a hammer shaft. An end sleeve is sleeved on the right side of the hammer shaft. An anti-vibration ring is sleeved on the middle part of the hammer shaft. Connectors are uniformly arranged on the inner side of the anti-vibration ring. The inner side of the connecting body is uniformly provided with a hemispherical groove, and the inner side of the connecting body is uniformly provided with a first anti-vibration mechanism through the hemispherical groove. Attached with hammer head. This shock-absorbing new high-efficiency hardware tool hammer is equipped with a first anti-vibration mechanism. When receiving the vibration transmitted by the hammer shaft, multiple first anti-vibration mechanisms reduce the vibration frequency by moving sideways and lowering the contact surface, so as to suppress the vibration. Conduction reduces the vibration amplitude and frequency of the hand, thereby reducing the vibration friction of the hand and protecting the hand.

Owner:如东恒发五金制品有限公司

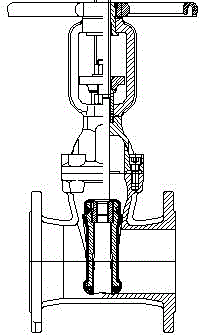

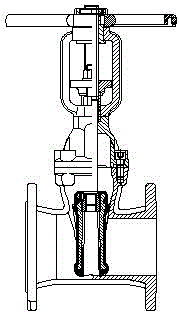

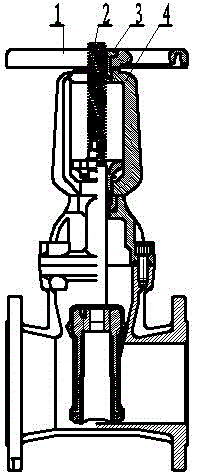

Compact rising stem gate valve

The invention discloses a compact-type rising-stem gate valve which comprises a hand wheel, a screw rod, a valve-stem nut and a support. The cross section of a screw cap of the valve-stem nut is polygonal and the longitudinal section of the same is wedged, a sunken platform matched with the screw cap of the valve-stem nut in shape is arranged at the position where the hand wheel is matched with the valve-stem nut, a triangular boss protruding outwards is arranged at the bottom edge of the valve-stem nut, and a triangular groove matched with the triangular boss in shape is arranged at the position where the support is matched with the valve-stem nut. The compact-type rising-stem gate valve has the advantages that torque the hand wheel passes to the valve-stem nut is increased since the screw nut of the valve-stem nut is polygonal, and the triangular boss structure arranged at the bottom edge and protruding outwards get rid of connecting pieces of check head screws, fine threads and the like, therefore the compact-type rising-stem gate valve is low in cost, simple in structure, easy to assemble, reliable in work and long in service life; friction vibration between the hand wheel and the support can be alleviated through a gasket, and abrasion between the hand wheel and the support is avoided; made of aluminum bronze, the valve-stem nut is high in strength and good in abrasion performance and corrosion resistance.

Owner:ANHUI TONGDU FLOW TECH

A kind of graphite/aluminum base self-lubricating sliding bearing containing graphene and preparation method thereof

ActiveCN107269704BImprove shock absorptionGood self-lubricating performanceBearing componentsSelective laser sinteringGraphite

Owner:CHINA THREE GORGES UNIV

Self-adaptive material internal and external friction device for high-speed cutting

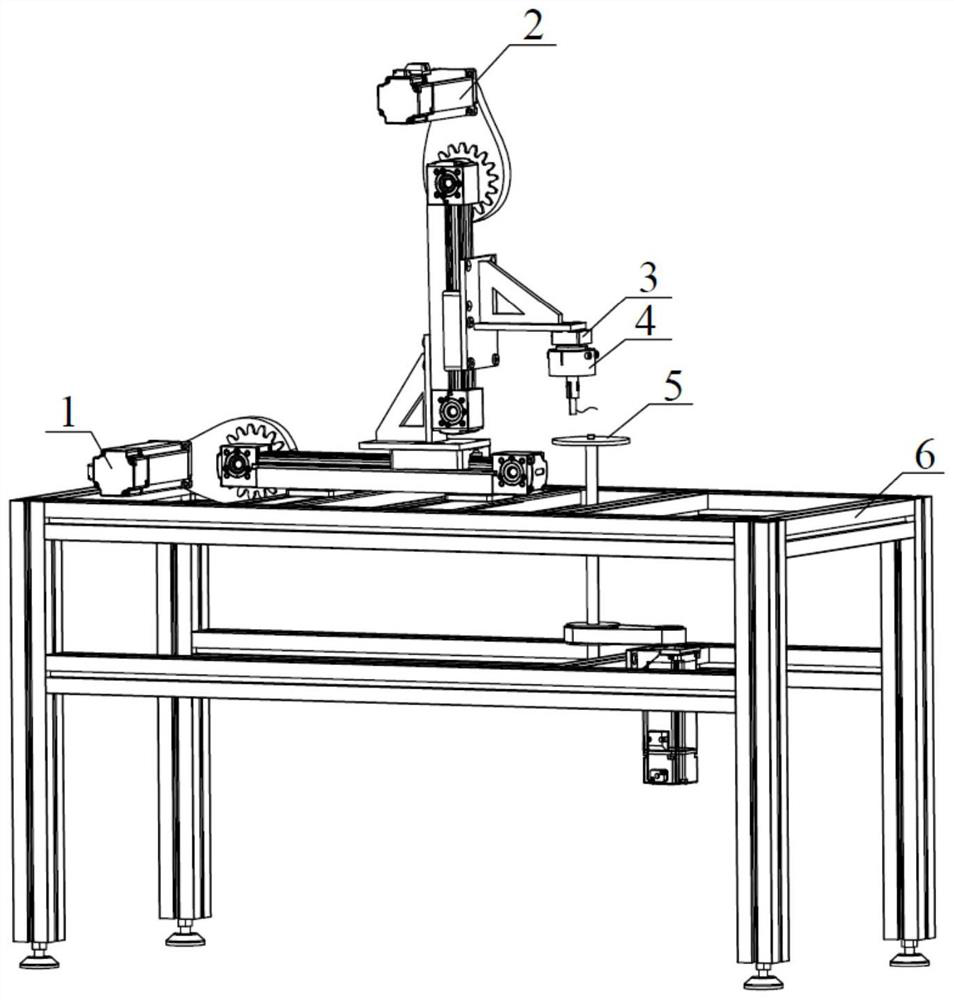

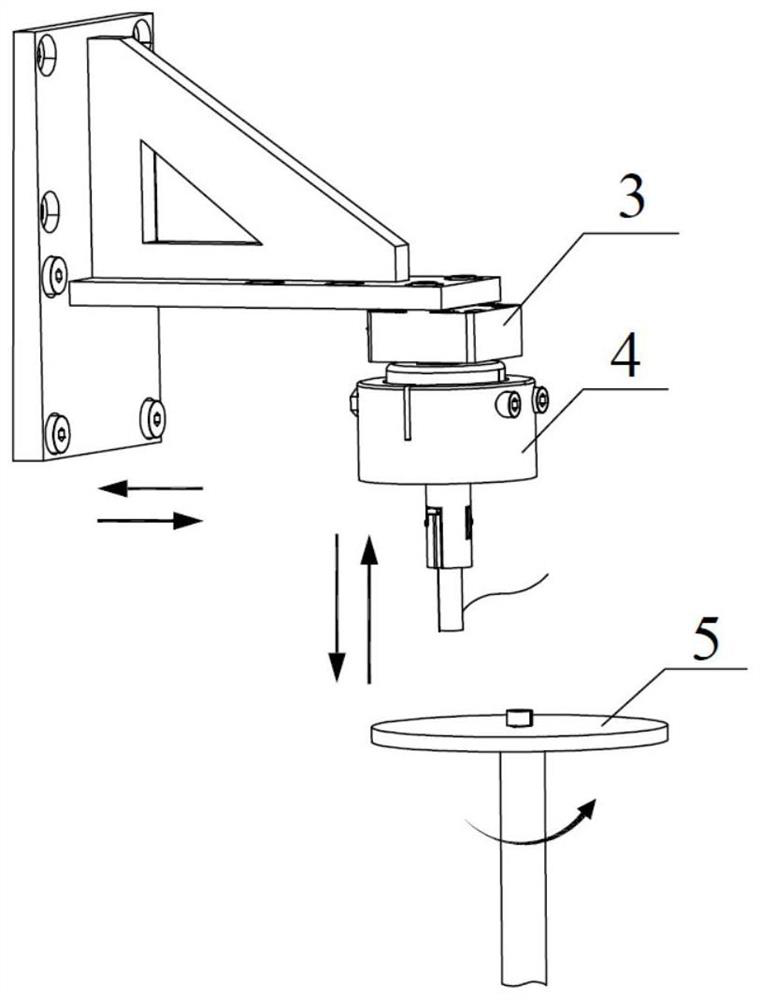

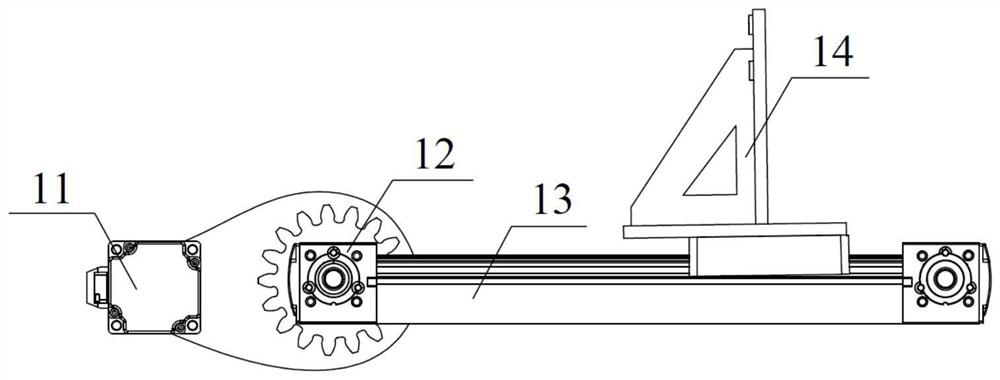

PendingCN114705577AGuaranteed accuracyReduce vibration frictionUsing mechanical meansInvestigating abrasion/wear resistanceEngineeringSelf adaptive

The invention relates to the technical field of high-speed cutting, and discloses a self-adaptive material internal and external friction device for high-speed cutting. Comprising a rack, a horizontal driving transmission mechanism and a lower friction pair which are arranged on the rack, a vertical driving transmission mechanism which is in sliding fit with the horizontal driving transmission mechanism, a force and temperature measurement acquisition mechanism and an upper friction pair which are arranged on the vertical driving transmission mechanism, and a main control board, the horizontal driving transmission mechanism drives the vertical driving transmission mechanism and the upper friction pair to translate in the horizontal direction; the vertical driving transmission mechanism drives the upper friction pair to translate in the vertical direction, so that the upper friction pair and the lower friction pair perform friction motion; the force and temperature measurement acquisition mechanism acquires loading force and temperature information of an upper friction pair in friction motion; and the main control board adjusts the friction position according to the received loading force information. The friction test can be reliably carried out, the position of a friction point can be adaptively adjusted, and the device is simple in overall structure, reliable and easy to implement.

Owner:BEIJING FORESTRY UNIVERSITY

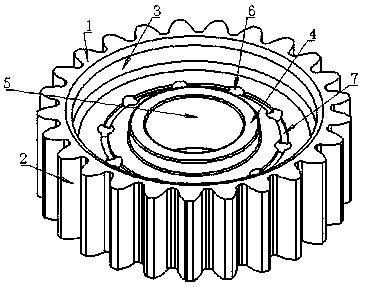

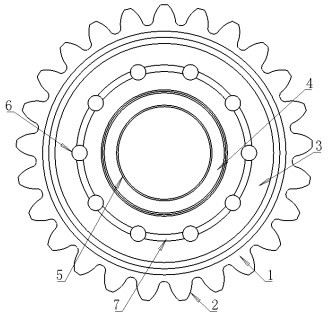

Special high-leakproofness connecting gear

InactiveCN108953553AImprove stabilityImprove shock absorptionPortable liftingGearing elementsEngineeringMechanical engineering

Owner:TAIZHOU LIHUA GEAR MFG

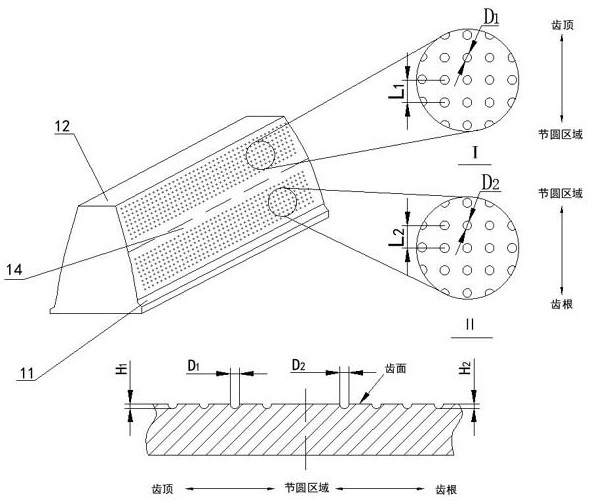

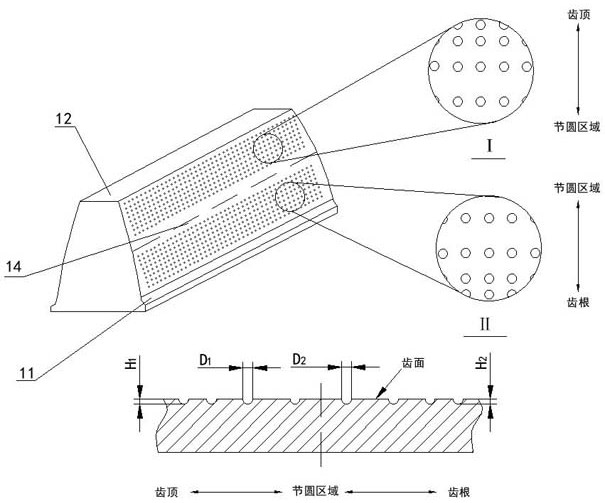

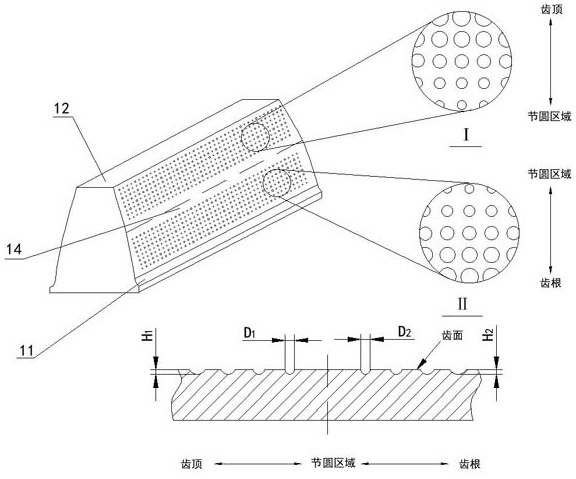

Heavy-duty gear capable of improving bearing capacity of lubricating oil film

PendingCN114352700AAvoid pittingAvoid wear and tearGear vibration/noise dampingPortable liftingRooted toothGear wheel

The invention discloses a heavy-duty gear capable of improving the bearing capacity of a lubricating oil film. The heavy-duty gear comprises a gear tooth body, the gear tooth body comprises a tooth root, a tooth crest and a tooth surface, the intersecting line of the tooth surface and an indexing cylindrical surface is a tooth line, the intersecting line area of a pitch circle and the tooth surface during gear meshing is a pitch circle area, and the tooth line is located in the pitch circle area; and pits are formed in the surface of the tooth surface. The gear with the pit structures on the tooth surface has the beneficial effects that the gear with the pit structures on the tooth surface is provided according to the performance requirements of comprehensively optimizing surface friction wear and vibration noise in the gear tooth meshing process. The non-pitch circle area of the tooth surface is provided with the circular pit structure, on one hand, more lubricating media can be stored, the oil film thickness is effectively increased, the oil film temperature rise is reduced, the tooth surface friction and wear performance is improved, and the service life is prolonged; and on the other hand, in the gear tooth meshing process, due to the existence of the pit structures, the tooth surface meshing contact state changes, the stress concentration phenomenon is relieved, and tooth surface energy accumulation and friction vibration are effectively reduced.

Owner:JIANGSU UNIV

Novel efficient damping hardware tool hammer

ActiveCN113618680AWeakening rangeReduce frequencyHand hammersMetal-working hand toolsComputer hardwareVibration amplitude

The invention discloses a novel efficient damping hardware tool hammer, and relates to the technical field of hardware. The novel efficient damping hardware tool hammer comprises a hammer rod, the right side of the hammer rod is sleeved with an end sleeve, the middle of the hammer rod is sleeved with an anti-vibration ring, connecting bodies are evenly arranged on the inner side of the anti-vibration ring, hemispherical grooves are evenly formed in the inner sides of the connecting bodies, first anti-vibration mechanisms are evenly arranged on the inner sides of the connecting bodies through the hemispherical grooves, the left side of the hammer rod is in threaded connection with an anti-vibration rod, and the left side of the anti-vibration rod is in threaded connection with a hammer head. According to the novel efficient damping hardware tool hammer, first anti-vibration mechanisms are arranged, and when vibration conducted by the hammer rod is received, the multiple first anti-vibration mechanisms reduce the vibration frequency in the mode of lateral movement and contact surface reduction, so that vibration conduction is restrained, the vibration amplitude and frequency of a hand are reduced, and therefore vibration friction of the hand is reduced, and the hand is protected.

Owner:如东恒发五金制品有限公司

Split type grinder, wheel tread cleaning device of railway vehicle, and railway vehicle

The invention relates to a split type grinder, a wheel tread cleaning device for a railway vehicle, and the railway vehicle. The split type grinder comprises: a connecting piece, wherein the connecting piece is detachably mounted on a brake head of the railway vehicle; and at least two grinding sub-assemblies, wherein each grinding sub-assembly has a friction body and a support body, the friction body is arranged to provide a surface for frictional contact with a wheel tread of a rail vehicle and is connected to the connecting piece by the support body, and a gap is provided between at least two of the grinding sub-assemblies. The split type grinder is easy to manufacture, install and maintain, the temperature of the friction surface of the grinder in the using process can be effectively reduced, the probability that a wheel is scratched due to metal inlaying of the grinder is reduced, the influences of friction vibration, impact and noise are reduced, and the whole system is more stable and reliable.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Energy-saving and environment-friendly lubricating oil for internal combustion engine capable of self-repairing wear and preparation method thereof

ActiveCN107488491BWon't fall offWork effectively for a long timeLubricant compositionFuel oilFriction modifier

The invention discloses energy-saving and environment-friendly lubricating oil capable of self-repairing wear for an internal combustion engine and a preparation method of the energy-saving and environment-friendly lubricating oil, and belongs to the field of lubricating materials. The energy-saving and environment-friendly lubricating oil is prepared from the following components in percentage by weight: 87 to 90 percent of base oil and 10 to 13 percent of additive, wherein the additive is prepared from the following components in percentage by weight: 1.2 to 2.5 percent of a calcium-containing clearing agent, 1.3 to 2 percent of a dispersing agent, 0.5 to 1.4 percent of an anti-wear agent, 1.5 to 2.5 percent of an antioxidant, 0.5 to 0.8 percent of a corrosion inhibitor, 1.5 to 2 percent of a viscosity index improver and 1.1 to 3.5 percent of a friction improver; the friction improver is polytetrafluoroethylen high-molecular compound ultramicro nano-powder and the particle size of the powder is 2 to 12 nm. According to the energy-saving and environment-friendly lubricating oil disclosed by the invention, the problem that existing lubricating oil for the internal combustion engine cannot repair friction and wear of internal parts in the engine is solved; in addition, the design tolerance gap can be automatically compensated and non-disassembly in-situ repair can be carried out, thereby improving the sealing property of a cylinder, a piston and other parts; in addition, a compression ratio and an air-fuel ratio of the engine are improved, fuel oil is combusted more sufficiently, the discharge of exhaust pollutants is reduced and the frictional resistance is reduced.

Owner:安徽游能润滑新技术有限公司

Ball milling machine used for machining building material and using method thereof

The invention discloses a ball milling machine used for machining a building material and a using method thereof. The ball milling machine comprises a bottom plate. An air compressor is arranged on the upper portion of the bottom plate. A first air pipe is arranged on the front portion of the air compressor. An air pipe support is arranged on the front portion of the first air pipe. A second air pipe is arranged on the upper portion of the air pipe support. A third air pipe is arranged on one side of the second air pipe. A supporting disc is arranged on one side of the third air pipe. An air spray opening is formed in one side of the supporting disc. Bearing gear shaft supports are arranged on the upper portion of the bottom plate. Bearing gear shafts are arranged on the upper portions ofthe bearing gear shaft supports. Bearing gears are arranged on the bearing gear shafts. A motor is arranged on the rear sides of the bearing gears. According to the ball milling machine, the four bearing gears and the bearing gear supports are arranged, a grinding drum can be elevated, and vibrating friction and noise are reduced. A screen and an air compressor are arranged, and therefore workersdo not need to take out finished products manually. A first transmission gear and a second transmission gear are arranged, welding connection and gear transmission are adopted, reliability of equipment is improved, and the production efficiency is improved.

Owner:长兴坤泓环保材料有限公司

Mechanical, electronic and hydraulic brake equipment

InactiveCN107640145AReduce vibration frictionPlay a buffer roleBraking action transmissionBraking componentsEngineeringPulp and paper industry

The invention discloses mechanical, electronic and hydraulic brake equipment. The mechanical, electronic and hydraulic brake equipment structurally comprises a main cylinder connecting pipe, a communicating part, a first gasket, a cylinder body, a second gasket, an oil pipe, a shunting pipeline, a hydraulic guide pipe and a buffer and is characterized in that the cylinder body is of a circular cylinder structure, the cylinder body is transversely cut into two parts, the surface connecting line section of the cylinder body is rectangular, the left-right section of the cylinder body is semicircular, the left-right radial through hole of the cylinder body is integrally formed, the main cylinder connecting pipe is arranged on the left side of the cylinder body, the communicating part is arranged in the radial inner cavity of the cylinder body, the first gasket is arranged on the left side of the inner cavity of the cylinder body, the left end of the hydraulic guide pipe penetrates the cylinder body and is connected with the main cylinder connecting pipe, and the oil pipe is arranged in the inner cavity of the cylinder body and extends out. The mechanical, electronic and hydraulic brakeequipment has the advantages that the equipment is provided with the buffer, the hydraulic damping principle is used, the main cylinder and a wheel cylinder body vibrate during equipment operation, alarge amount of kinetic energy is consumed in the compressing process of a damper, a buffering effect is achieved, cylinder body vibration and friction are reduced, noise is lowered effectively, andequipment service life is prolonged.

Owner:喜读(上海)物联网科技有限公司

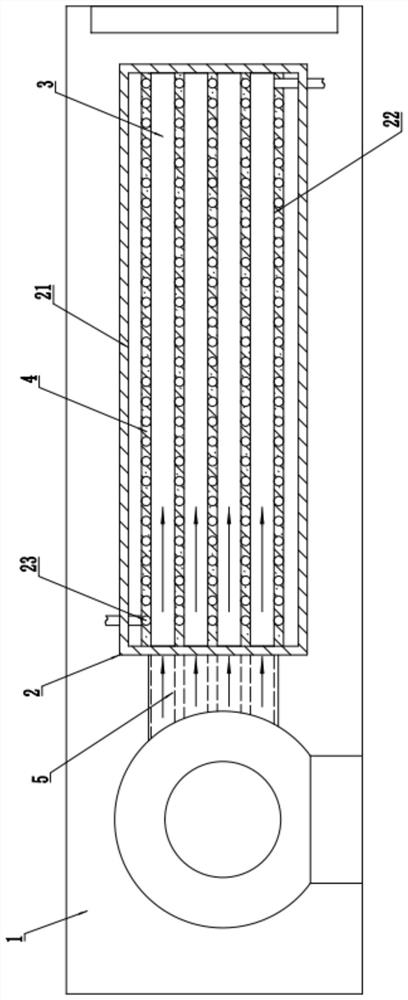

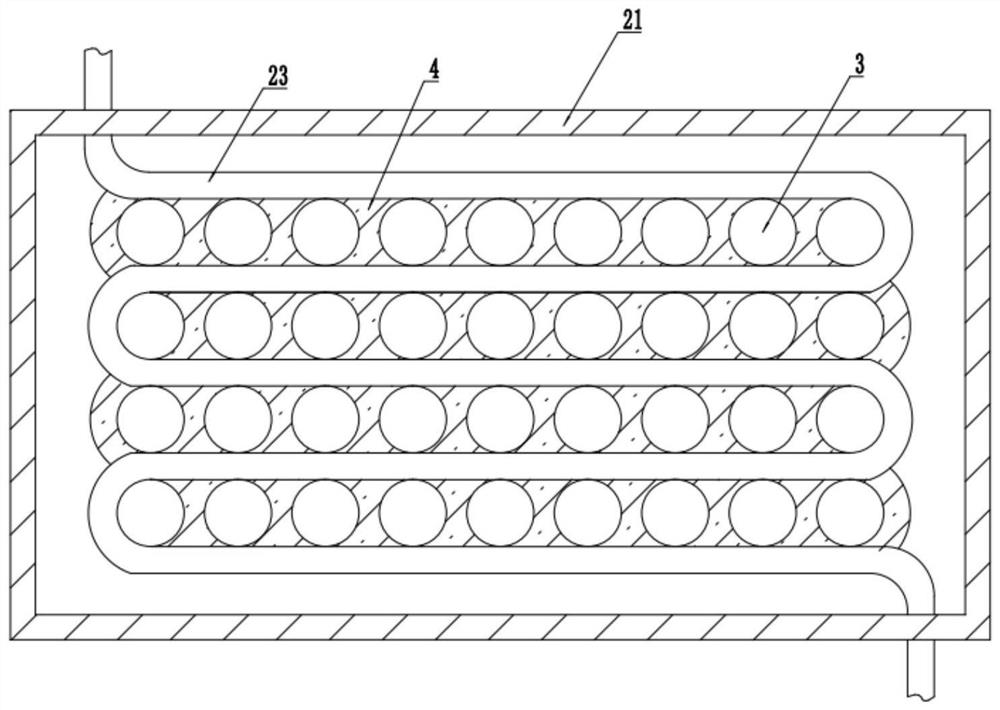

Noise reduction structure of ceiling type air conditioner

PendingCN114459140AReduce vibration frictionReduce wind resistanceLighting and heating apparatusNoise suppressionEngineeringMechanical engineering

One or more embodiments of the specification provide a ceiling type air conditioner noise reduction structure which is arranged in an air conditioner indoor unit body and comprises a surface air cooler arranged in the indoor unit body, one end of the surface air cooler is correspondingly provided with an air inlet, the other end of the surface air cooler is correspondingly provided with an air outlet, and a plurality of through air channels are formed in the surface air cooler in the direction parallel to airflow. Therefore, inlet air is directly blown into all the through air channels for air outlet and heat exchange, air resistance, namely friction vibration between airflow and the surface air cooler, is greatly reduced, meanwhile, the outer sides of all the through air channels are wrapped with the silencing parts in a surrounding mode, the divided air channels are subjected to silencing and noise reduction one by one, silencing and noise reduction treatment is more sufficient and effective, and the service life of the surface air cooler is prolonged. And the occupied space in the air conditioner is not additionally increased.

Owner:安徽美博智能电器集团有限公司

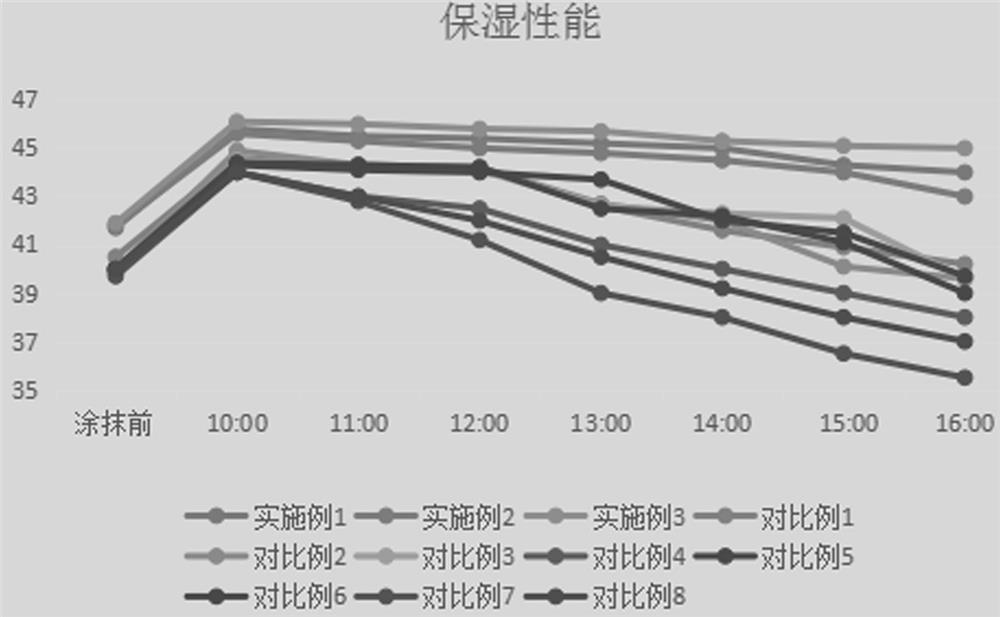

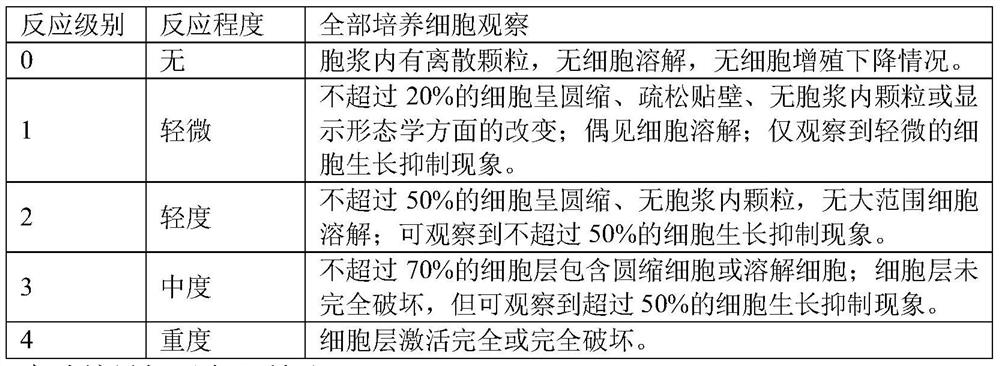

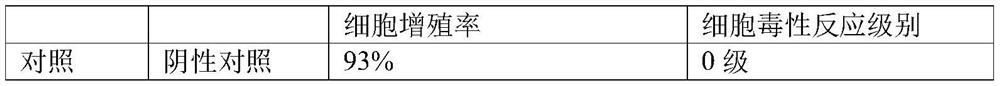

Snore stopping composition

PendingCN112220751AReduce foreign body sensationGood moisturizing effectInorganic non-active ingredientsSolution deliveryGlycerol dioleateGlycerol

The invention provides a snore stopping composition. The snore stopping composition comprises an emulsifier, a humectant, a stabilizer, a corrigent, a pH regulator, a preservative and water, wherein the emulsifier is selected from one or more of polysorbate-60, polysorbate-80, polysorbate-85, polyglycerol-3 methyl glucose distearate, polyglycerol-10 stearate, polyglycerol-10 myristate, polyglycerol-10 dioleate, polyglycerol-10 laurate, polyglycerol-10 isostearate, polyglycerol-10 oleate, polyglycerol-10 di-isostearate, polyglycerol-6 laurate and polyglycerol-6 myristate. The snore stopping composition is refreshing in use, free of foreign matter residues, lasting in moisturizing effect and high in safety.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

Composite non-woven fabric structure with imitation turf layer laid on surface

InactiveCN112982077AReduce concentrationImprove use comfort performanceGround pavingsEngineeringStructural engineering

The invention provides a composite non-woven fabric structure with an imitated turf layer laid on the surface. The composite non-woven fabric structure comprises an outer imitated turf layer, side imitated turf layers, side reinforcing strips, fluorescent strips and a damping layer. The outer end of the outer imitation turf layer is fixedly connected with an outer non-slip mat layer; the side imitation turf layer is positioned below the outer non-slip mat layer; the side reinforcing strips are fixedly connected to the side ends of the outer imitation turf layer and the side imitation turf layers through screws; the fluorescent strip is fixedly connected to the front side of the connecting folded plate of the outer non-slip mat layer; the damping layer is fixedly connected to the lower surface of the outer imitation turf layer; a water seepage layer is fixedly connected to the lower surface of the outer imitation turf layer, water seepage holes are formed in the surface of the water seepage layer, the upper half portions of the water seepage holes are conical holes with the conical ends facing downwards, and the lower sides of the water seepage holes are cylindrical holes, so that the use comfort of the outer imitation turf layer is improved, and vibration friction to joints during step descending is relieved; the connection firmness of the side imitation turf layer, the outer non-slip mat layer and the outer imitation turf layer is improved, and the edge warping probability is reduced.

Owner:王介文

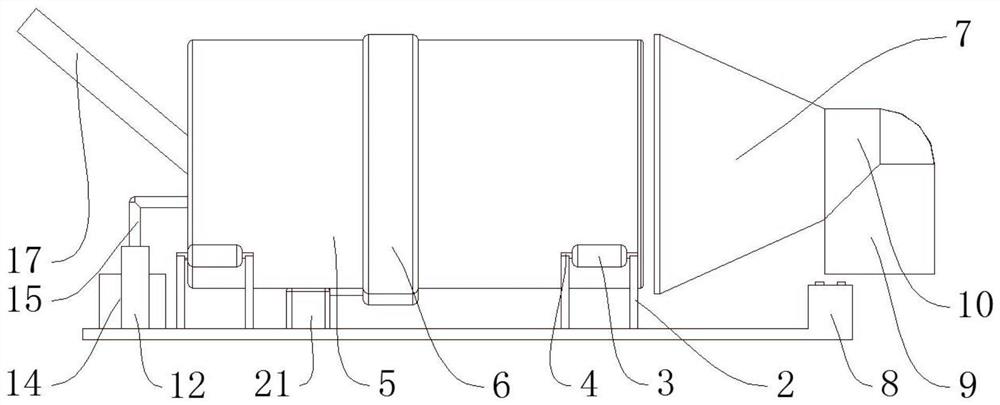

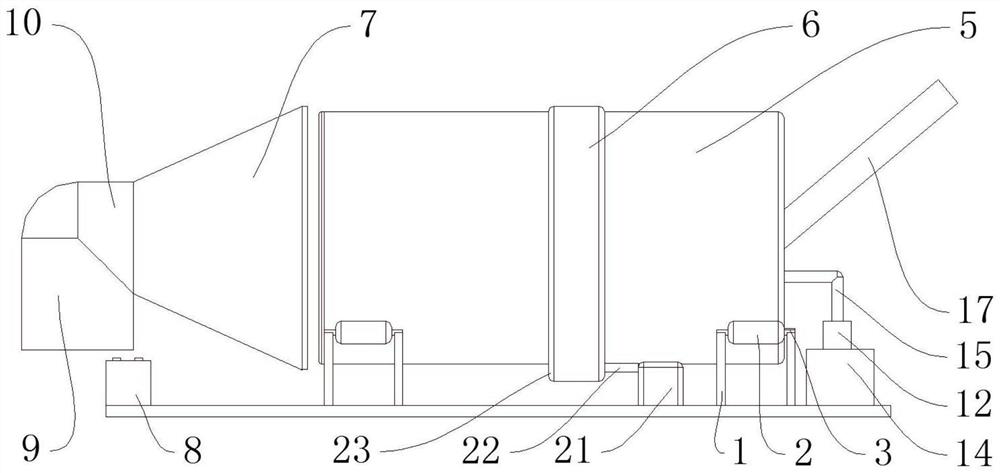

Multifunctional low-noise vibration structure

ActiveCN112603798AReduce frictionReduce vibration frictionChiropractic devicesSofasStructural engineeringControl theory

The invention relates to the technical field of vibration structures, and particularly discloses a multifunctional low-noise vibration structure which comprises a fixed frame, a movable frame and a first driving piece, and the first driving piece drives the movable frame to move back and forth relative to the fixed frame; a second driving piece drives a lifting frame to move relative to the movable frame; a rolling guide rail unit comprises a fixed seat, a movable seat and a roller part arranged between the fixed seat and the movable seat in a rolling manner, the fixed seat is arranged on a fixed frame, and the movable frame is arranged on the movable seat; the fixed seat is provided with a first groove body, the movable seat is provided with a second groove body, and the two ends of the roller part are contained in the two groove bodies respectively. A user can place the head or the legs on the lifting frame after the second driving piece moves; by means of the structural arrangement of the roller part of the rolling guide rail unit, the friction force between the fixed frame and the movable frame is reduced, abrasion between the fixed frame and the movable frame is delayed, vibration friction of the vibration structure is reduced, service life is prolonged, and operation stability of the vibration structure is improved.

Owner:广东诺奖健康科技有限公司

Novel high-sealing-performance connecting gear

PendingCN112728042AImprove stabilityImprove shock absorptionPortable liftingGearing detailsGear wheelIndustrial engineering

The invention relates to the technical field of gear structures, in particular to a novel high-sealing-performance connecting gear. According to the technical scheme adopted by the novel high-sealing-performance connecting gear, the novel high-sealing-performance connecting gear comprises a cylindrical gear structure main body connecting column, clamping assembly connecting grooves which are evenly distributed in a circumference mode are formed in the outer cylindrical surface of the gear structure main body connecting column, the clamping assembly connecting grooves completely penetrate through the upper end face and the lower end face of the gear structure main body connecting column, the center positions of the upper end face and the lower end face of the gear structure body connecting column are each provided with a cylindrical sealing assembly connecting groove, and the center positions of the bottom faces of the sealing assembly connecting grooves are provided with an integrally-formed cylindrical fastening assembly connecting boss. The novel high-sealing-performance connecting gear has the advantages that the connection tightness of the gear structure in the assembling process is guaranteed, when the gear structure is used, the vibration and friction in the using process can be reduced, the stability of a part in the using process is effectively improved, and the service life of the gear structure in the using process is longer.

Owner:泰州市三立管件股份有限公司

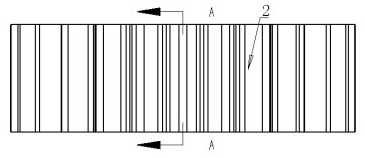

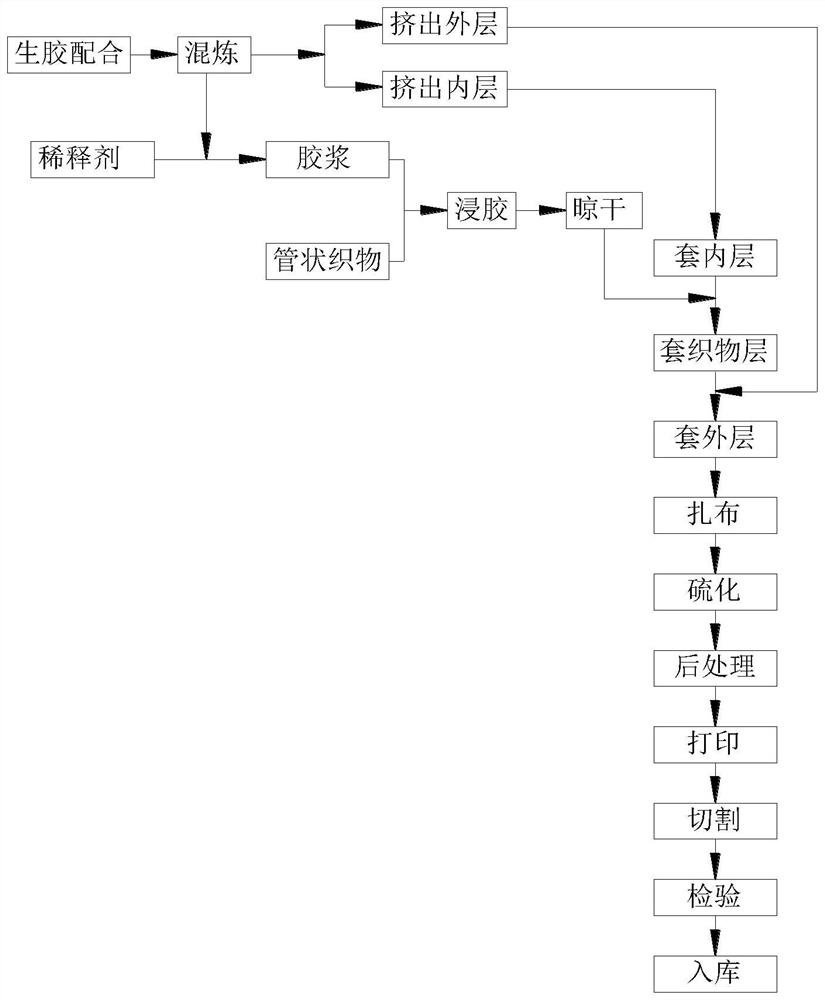

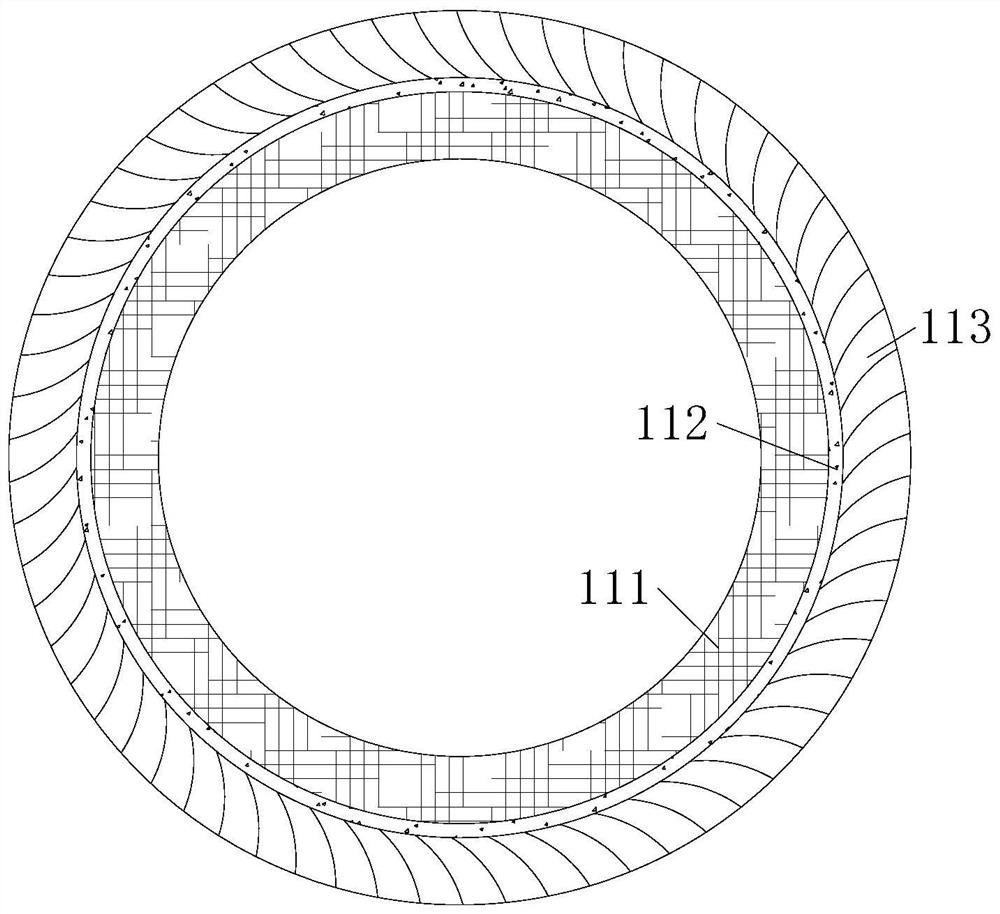

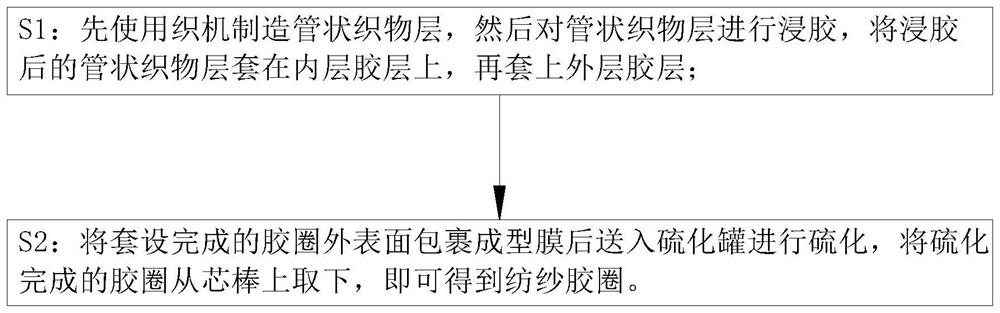

Spinning rubber ring produced by tubular fabric impregnation sleeving process

PendingCN114575004AHigh bonding strengthUniform force distributionDrafting machinesTextile/flexible product manufactureYarnRubber ring

The invention belongs to the technical field of spinning rubber ring production, and particularly relates to a spinning rubber ring produced by adopting a tubular fabric impregnation sleeving process, the production process of the spinning rubber ring comprises the following steps: S1, firstly manufacturing a tubular fabric layer by using a weaving machine, then impregnating the tubular fabric layer, sleeving the impregnated tubular fabric layer on an inner rubber layer, and forming a spinning rubber ring; sleeving an outer rubber layer; and S2, the outer surface of the sleeved rubber ring is wrapped with a forming film, then the rubber ring is fed into a vulcanizing tank to be vulcanized, the vulcanized rubber ring is taken down from the core rod, and the spinning rubber ring can be obtained. 1, the rubber ring is of a three-layer structure, the three layers are vulcanized into a whole, and the bonding strength is high; 2, the stress of the rubber ring is uniformly distributed during use; 3, the overall strength of the rubber ring is high; 4, the service life of the rubber ring is prolonged; and 5, the resultant yarn is good in dryness when spinning is used.

Owner:无锡市振华纺织橡胶器材有限公司

A non-contact brush seal and its manufacturing method

ActiveCN103883363BExtended service lifeIncreasing the thicknessLeakage preventionMachines/enginesBristleContact type

The invention discloses a non-contact type brush-type seal and a manufacturing method of the non-contact type brush-type seal. The non-contact type brush-type seal comprises a gland sealing ring, a front baffle and a rear baffle, wherein the front baffle and the rear baffle are arranged on the gland sealing ring. The front baffle, brush brittles and the rear baffle are welded into a whole. The front baffle is located on the air inlet side and is in riveting joint with an installation groove in the gland sealing ring so as to be assembled with the gland sealing ring. The non-contact type brush-type seal further comprises a U-shaped riveting groove. The U-shaped riveting groove is located on the air inlet side. A certain dip angle is formed by the brush brittles in the rotating direction of a rotor. The non-contact type brush-type seal has the remarkable advantages that the seal can be adapted to the transient bounce of the rotor, gaps are kept unchanged, the sealing effect of the seal is kept for a long time, the brush bristles are resistant to high temperature and long in service life and are arranged in the rotation direction of the rotor at a certain angle, friction vibration can be reduced, and influence on the safety of a unit is small. According to the manufacturing method of the non-contact type brush-type seal, it is guaranteed that the seal is not broken in the operation process, the high-performance welding technology is adopted to guarantee that the brush bristles do not fall off, the optimized brush bristle bunch thickness and height guarantee the high sealing performance, and the sealing effect is guaranteed.

Owner:大连保税区华鸿工业技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com