High-stability overrun clutch of electric bicycle

A technology for electric bicycles and overrunning clutches, applied to clutches, one-way clutches, mechanical equipment, etc., can solve problems such as clutch vibration, inflexible disengagement of special-shaped rollers, and reduced operating stability and reliability of electric bicycle drive trains, etc., to achieve Increase sliding resistance, improve running stability and reliability, and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

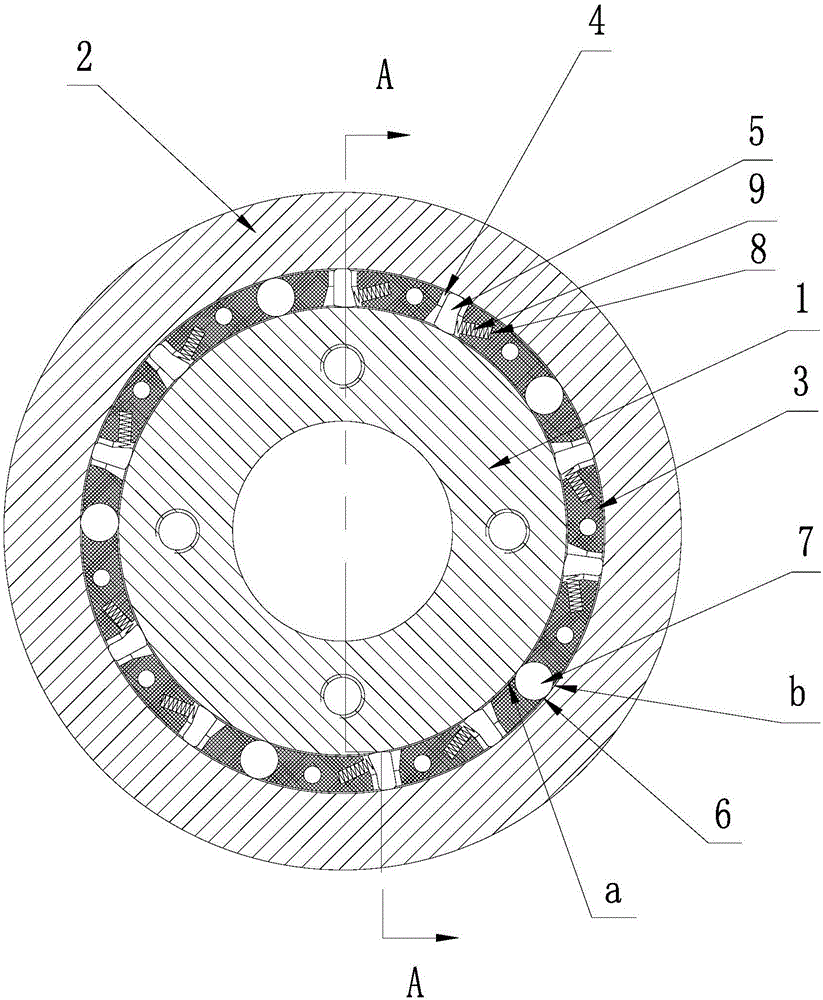

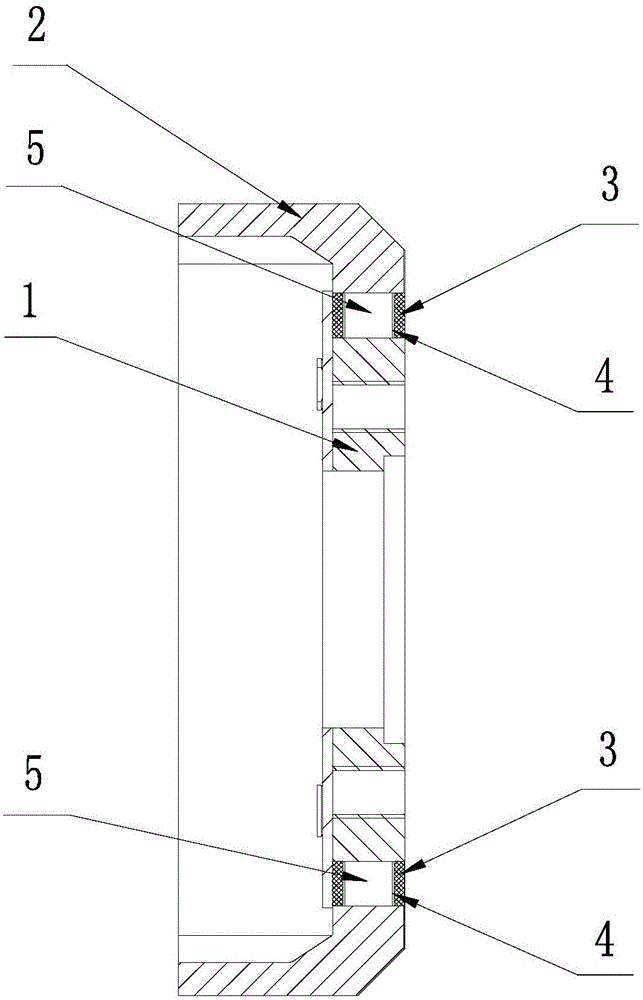

[0025] Example: Combine figure 1 and figure 2 Shown is a specific embodiment of the high-stability overrunning clutch for electric bicycles of the present invention. Like the conventional technology, it has an inner ring 1, an outer ring 2 and a cage 3 arranged between the inner and outer rings 1 and 2. The upper ring of the cage 3 is provided with several working grooves 4 in the circumferential direction, and special-shaped rollers 5 are arranged in the working grooves 4 . The side wall of each working groove 4 is provided with a spring clamping groove 8, and an auxiliary positioning spring 9 is provided in the spring clamping groove 8 which is in contact with the corresponding special-shaped roller 5, so as to enhance the locking of the special-shaped roller 5 force.

[0026] The main improvement of the present invention is that it is provided with several roller assembly holes 6 in the circumferential direction on the upper ring of the cage 3, and the roller assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com