Composite non-woven fabric structure with imitation turf layer laid on surface

A technology of turf layer and non-woven fabric is applied in the field of composite non-woven fabric structure, which can solve the problems of poor buffering effect, easy to cause slippage, and inconvenient discharge of water on steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

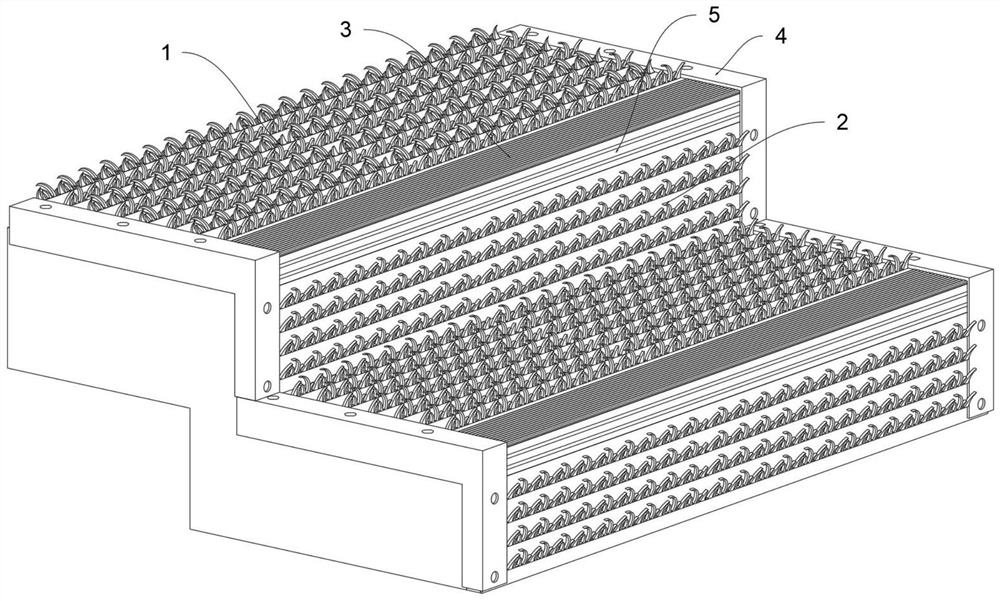

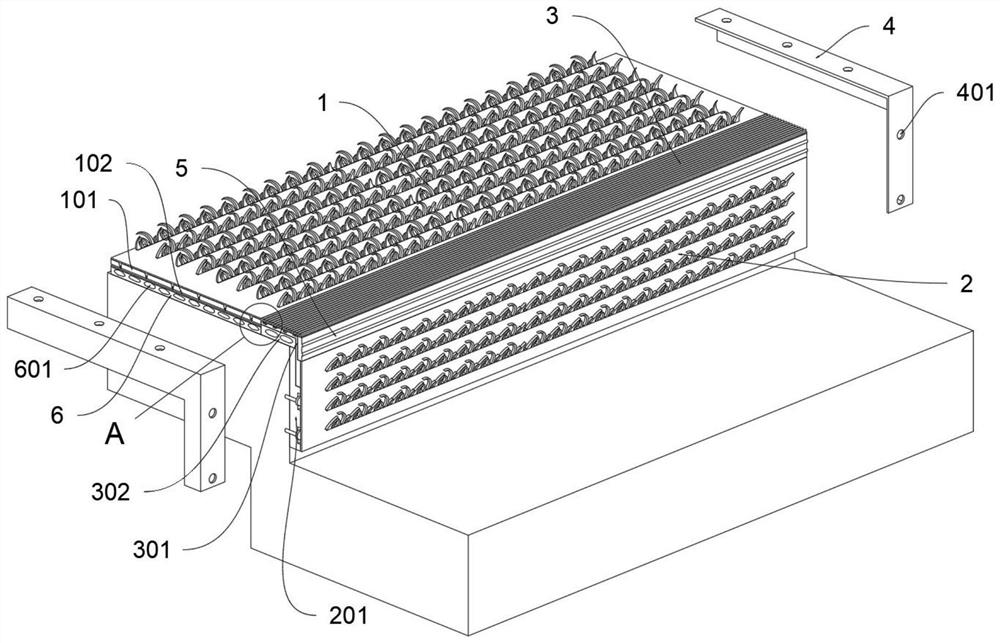

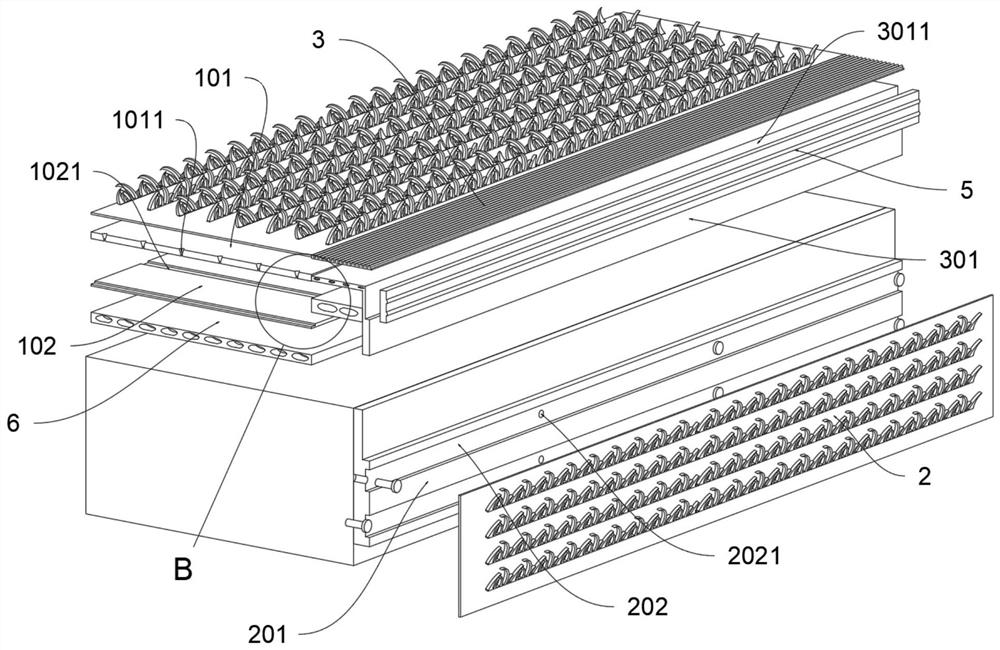

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a composite non-woven fabric structure with an imitation turf layer laid on the surface, comprising an outer imitation turf layer 1, a side imitation turf layer 2, a side reinforcement strip 4, a fluorescent strip 5, and a shock-absorbing layer 6; the outer imitation turf layer 1 The outer end is fixedly connected with an outer anti-skid cushion layer 3, and the lower surface of the outer imitation turf layer 1 is fixedly connected with a water seepage layer 101, and the surface of the water seepage layer 101 is provided with a water seepage hole 1011, and the upper half of the water seepage hole 1011 is a tapered end. Downward tapered holes, the underside of the water seepage hole 1011 is a cylindrical hole, the lower surface of the water seepage layer 101 is fixedly connected with the overflow layer 102, the outer imitation turf layer 1 of this structure is as figure 1 As shown, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com