Ball milling machine used for machining building material and using method thereof

A technology of building materials and ball mills, applied in grain processing, etc., can solve problems such as lowering production efficiency, manpower eradication, and noise generation, and achieve the effects of improving reliability, increasing production efficiency, and reducing vibration, friction, and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

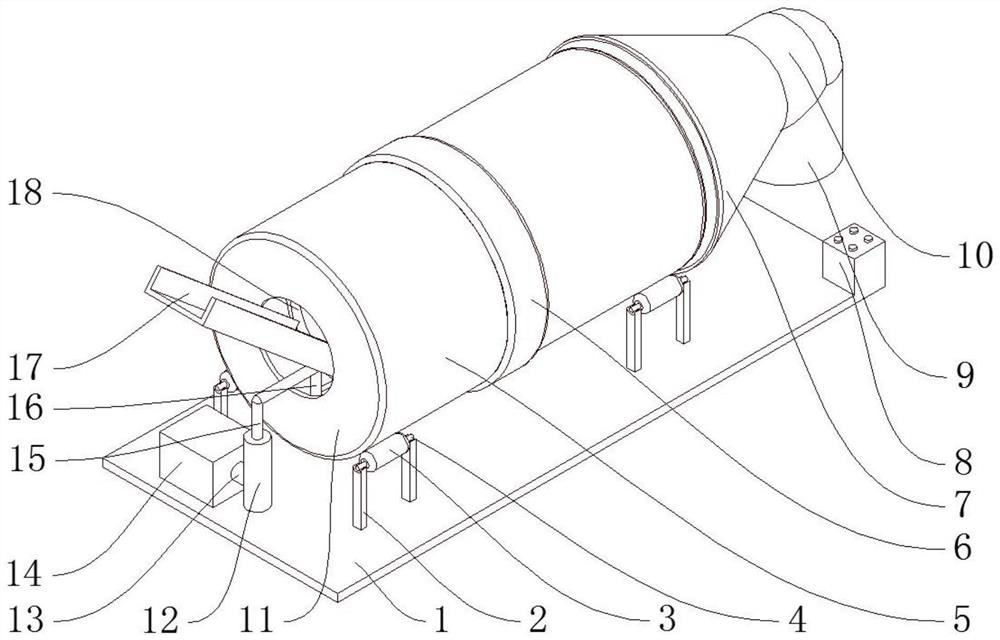

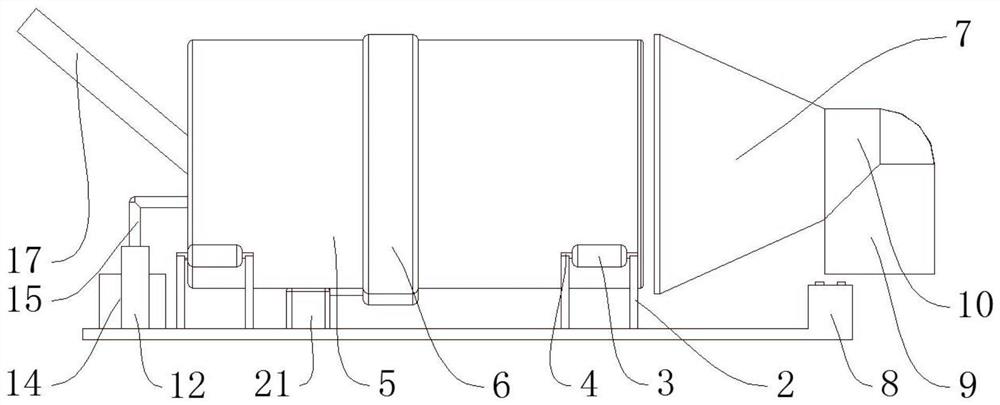

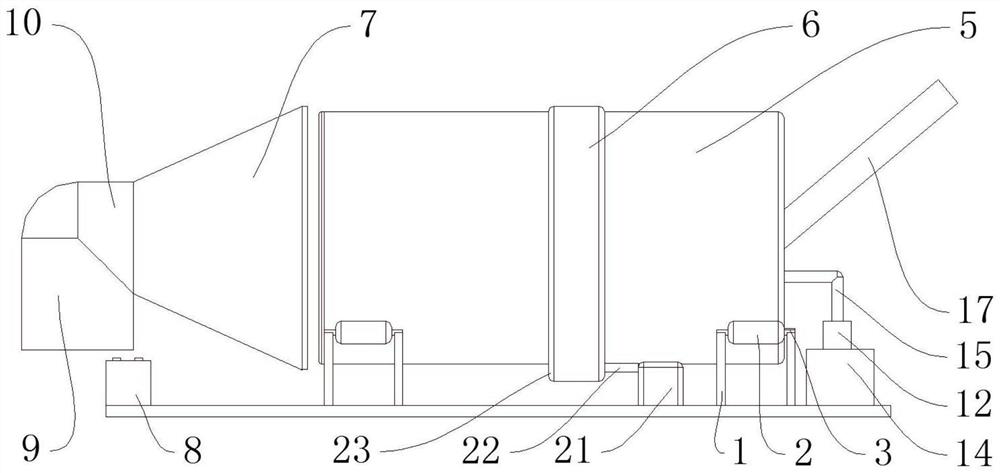

[0039] Such as Figure 1-Figure 6 As shown, the ball mill used for processing building materials includes a base plate 1, bearing components, an air compressor 14 is arranged on the upper part of the base plate 1 to generate compressed air, and a first air pipe 13 is arranged on the front of the air compressor 14 to transmit compressed air. The front part of the first air pipe 13 is provided with an air pipe support 12, carrying the second air pipe 15, the upper part of the air pipe support 12 is provided with a second air pipe 15, which transmits compressed air, and one side of the second air pipe 15 is provided with a third air pipe 16, which transmits compressed air, One side of the third air pipe 16 is provided with a supporting disc 18, which carries an air jet port 19, and one side of the supporting disc 18 is provided with an air jet port 19, which ejects compressed air. 4. The load-bearing gear shaft bracket 2 is provided with a load-bearing gear shaft 4 on the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com