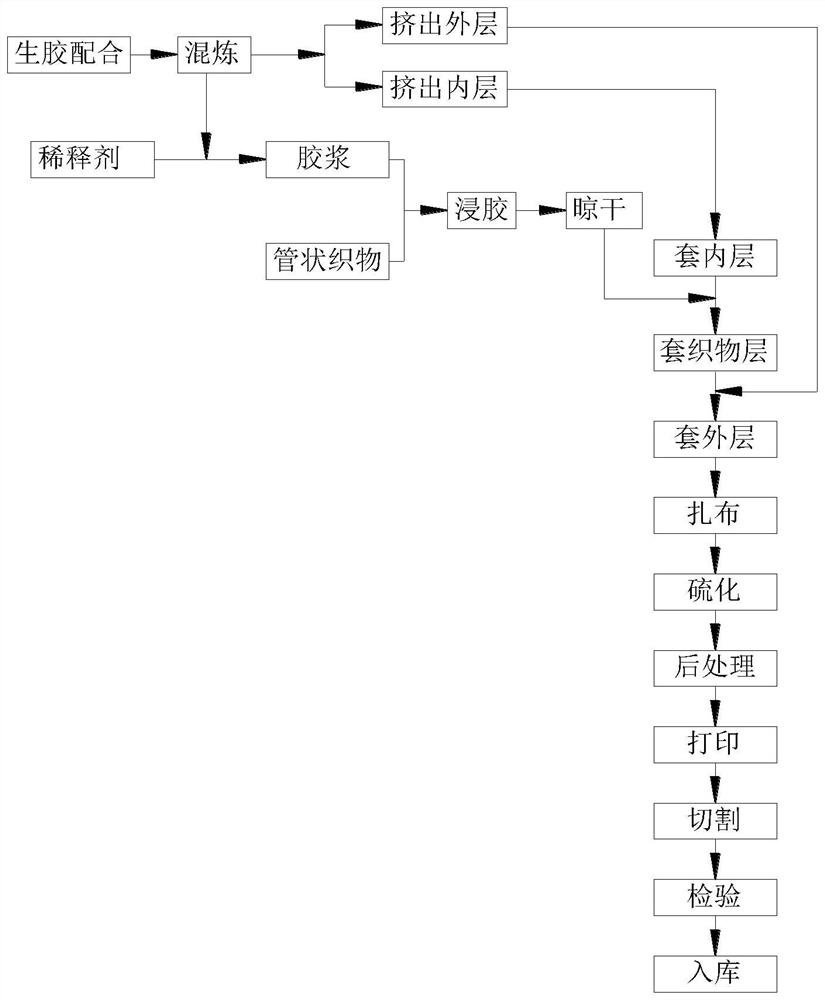

Spinning rubber ring produced by tubular fabric impregnation sleeving process

A tubular fabric and spinning apron technology, applied in the field of spinning apron production, can solve the problems of poor consistency of spinning aprons and easy unraveling of fabric threads, and achieve reduced vibration friction, high bonding strength, and improved use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

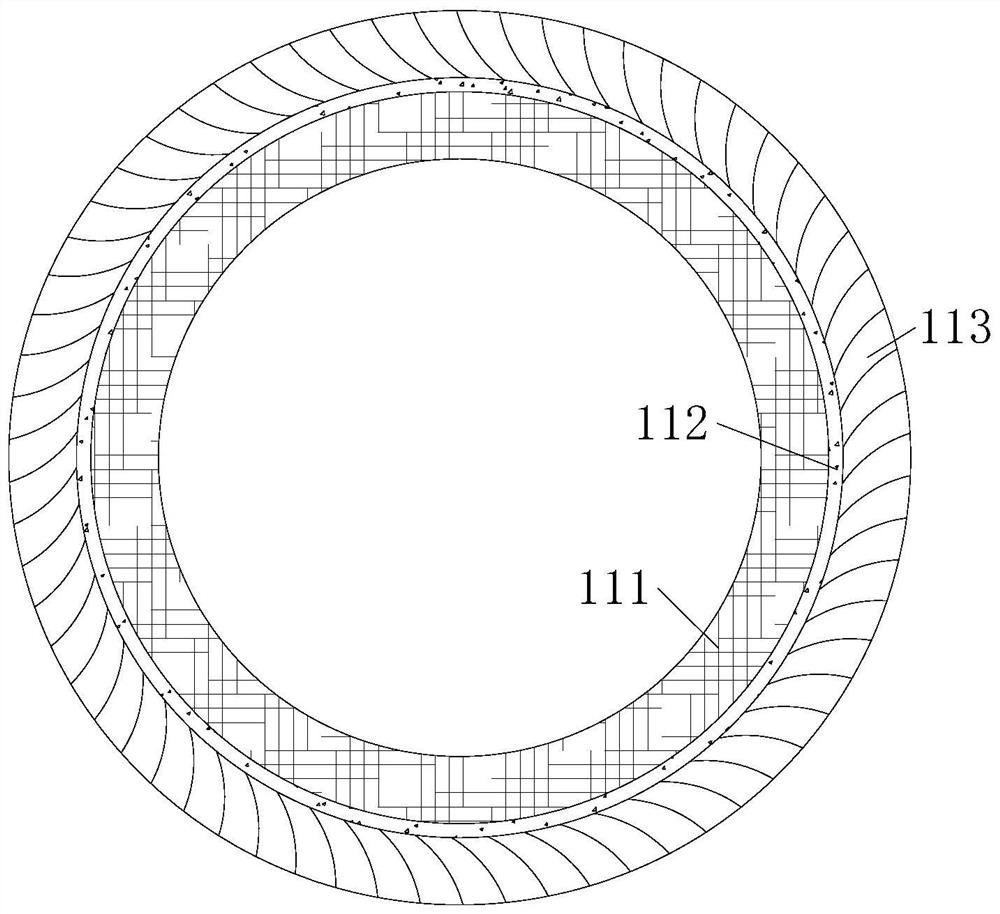

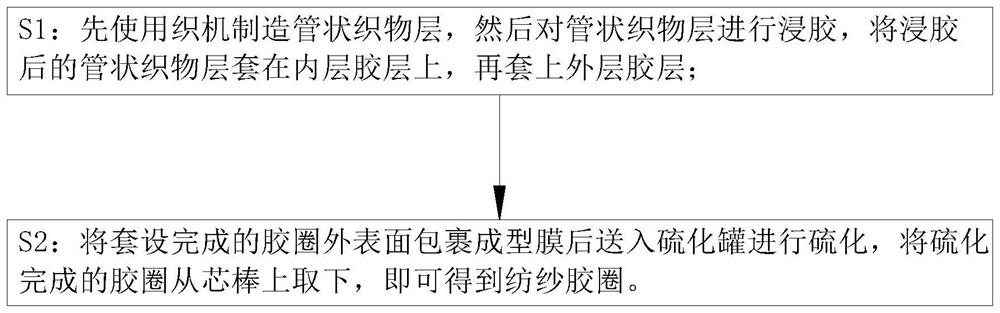

[0037] A spinning apron produced by a tubular fabric dipping and sheathing process, this embodiment is the skeleton structure of the product of the present invention, wherein the structure type is tubular fabric, and the molding method is direct sheathing.

Embodiment 2

[0039] A spinning apron produced by a tubular fabric dipping and sheathing process, this embodiment is a product skeleton structure in the prior art, wherein the structure type is a winding type, and the molding method needs to be formed on a machine.

Embodiment 3

[0041] A spinning apron produced by a tubular fabric dipping and sheathing process, this embodiment is a product skeleton structure of a fabric for an automobile hose, wherein the structure type is a braided type, and the molding method needs to be formed on a machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com