Compact rising stem gate valve

A compact, open-rod technology, which is applied to sliding valves, valve devices, engine components, etc., can solve the problems of complex assembly relationship between the valve stem nut and the handwheel, the valve stem nut is bulky, and the assembly steps are cumbersome, etc., and achieve a simple structure. , long service life, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

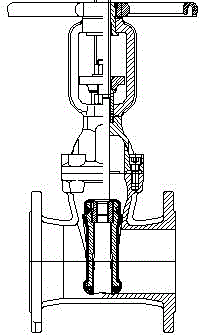

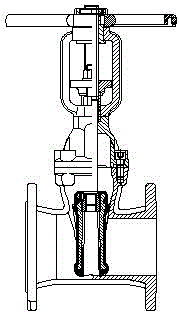

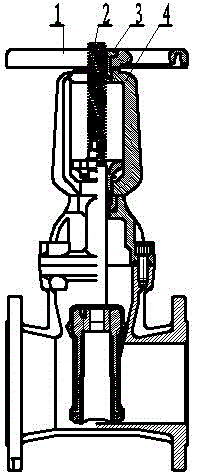

[0016] The present invention will be further described below with reference to the accompanying drawings.

[0017] like Figure 3-5 As shown, the present invention includes a handwheel 1, a screw rod 2, a valve stem nut 3 and a bracket 4. The cross section of the nut of the valve stem nut is polygonal, and the longitudinal section is wedge-shaped. There is a concave platform that matches the shape of the nut of the valve stem nut, the bottom edge of the valve stem nut is provided with a triangular convex platform that protrudes outward, and the bracket and the valve stem nut are provided with a triangular convex platform. Triangular grooves that match the shape of the table.

[0018] Specifically, the cross-section of the nut of the valve stem nut can be quadrilateral, pentagon, hexagonal, heptagonal, octagonal, and the more the number of sides, the greater the torque can be transmitted on the one hand, and the lower the torque on the other hand. The volume of the stem nut s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com