AGV docking system

A technology of traction mechanism and traction head, which is applied in traction connectors, elastic suspensions, suspensions, etc., can solve the problems of not being suitable for heavy load occasions, and achieve the effect of ensuring stability and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

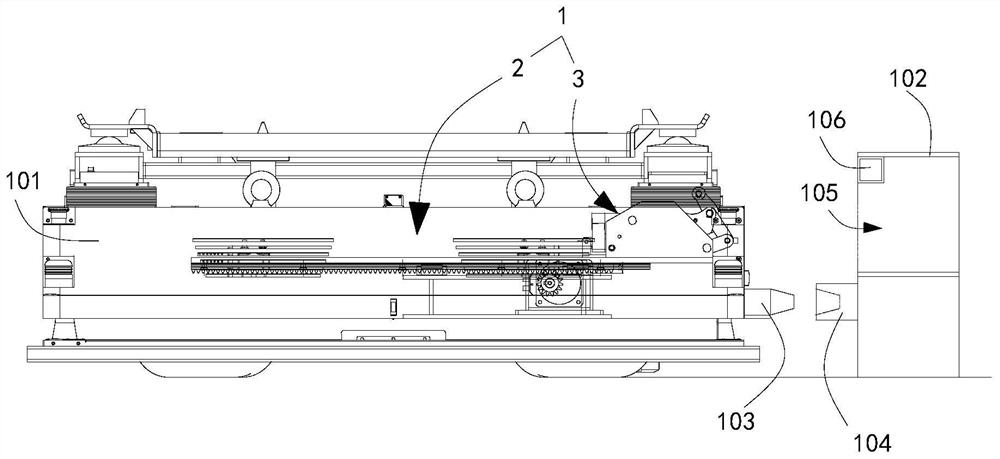

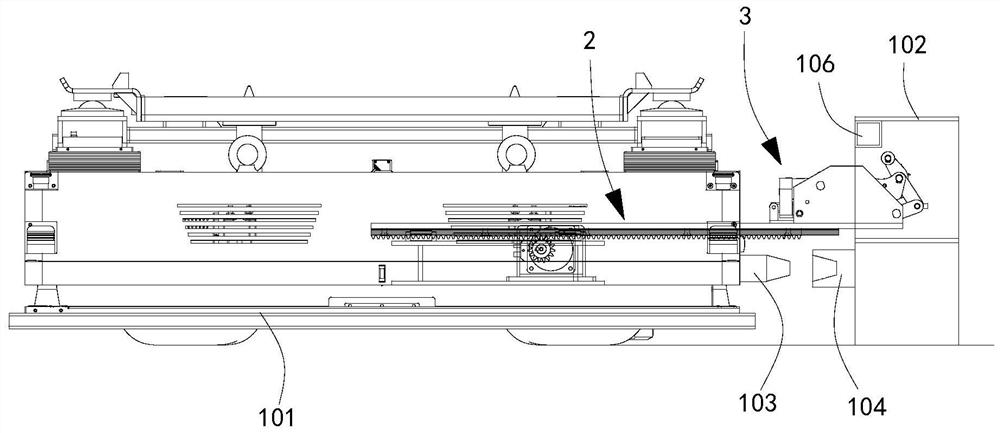

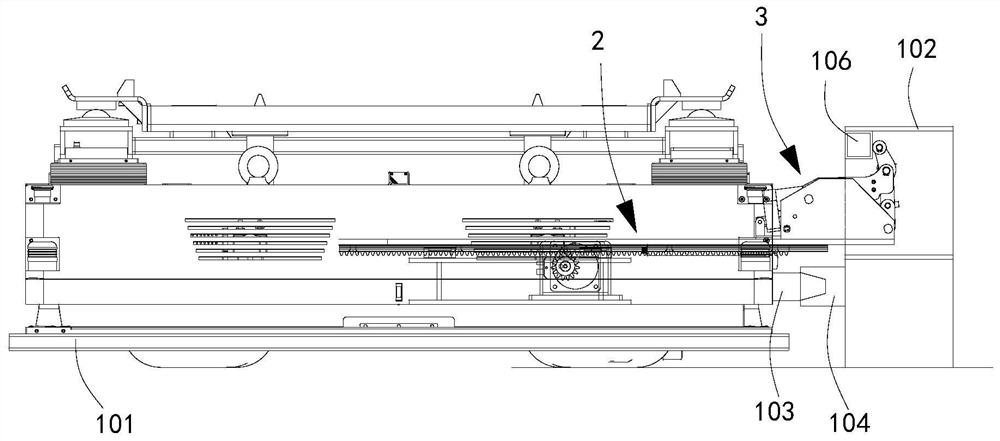

[0030] see Figure 1 to Figure 12, an AGV docking system, which includes a traction mechanism 1 and an adjustable drive device arranged on the AGV 101, and a traction and positioning workpiece 106 arranged on the line-side docking device 102, and the traction mechanism 1 can be extended or contracted to the outside of the AGV , the adjustable driving device can adjust the ground pressure of the driving wheel 52, the traction mechanism 1 includes a translation assembly 2 and a tractor 3, and the tractor 3 moves back and forth relative to the AGV101 through the translation assembly 2; the traction positioning workpiece 106 is used for It is docked with the tractor 3; wherein, it also includes a first plug-in guide 103 arranged on the AGV; and a second plug-in guide 104 arranged on the line edge docking device 102. When docking, the traction mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com