Front plate for semitrailer carriage body

A technology for the bottom plate and front plate of the carriage, which is applied in the direction of tractor-trailer combination, motor vehicles, vehicle parts, etc., and can solve the problems of unfavorable mechanical properties, local strengthening design, unstable structural strength and rigidity, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

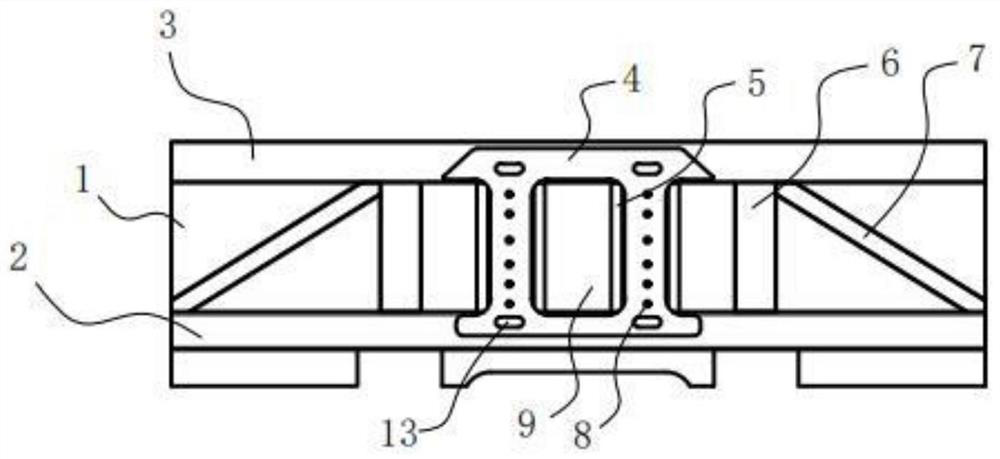

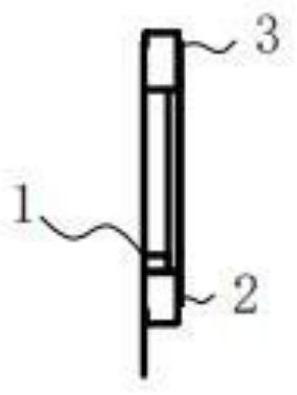

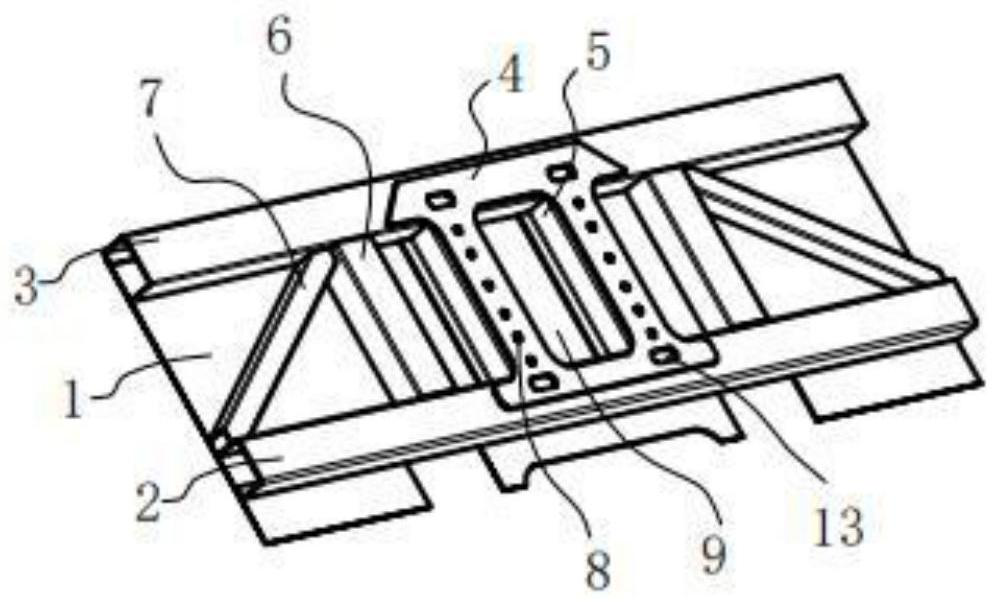

[0021] See attached Figures 1 to 7 , a front panel for a semi-trailer body, comprising a front panel body 1, an upper beam 3 fixed on the upper part of the outer panel surface of the front panel body 1, and a lower beam 2 fixed on the lower part of the outer panel surface of the front panel body 1 , a vertical beam 5 between the upper beam 3 and the lower beam 2; it is characterized in that: the vertical beam 5 is two, and the back surface of the vertical beam 5 is fixed on the outer surface of the reinforcing pad 4;

[0022] The cross-section of the upper beam 3 is groove-shaped, or / and the cross-section of the lower beam 2 is groove-shaped, or / and the cross-section of the vertical beam 5 is groove-shaped; a reinforcing backing plate is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com