Dyeing process of antibacterial magnetic knitted fabric

A knitted fabric and process technology, which is applied in the field of antibacterial magnetic knitted fabric dyeing process, can solve the problems of creases easily, dyeing is not firm, and knitted fabrics cannot be dried and stabilized, so as to prevent color from falling off, creases, and color the shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

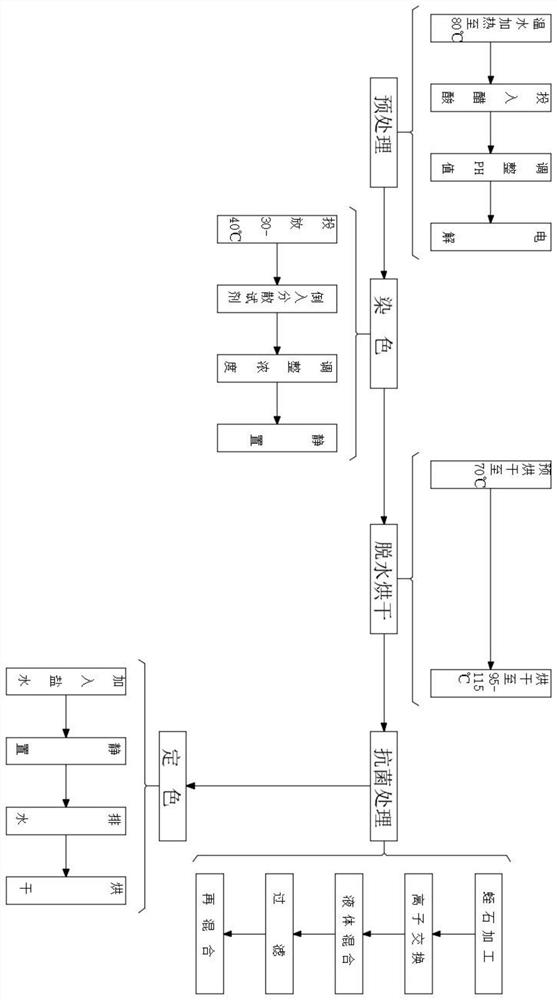

Image

Examples

Embodiment Construction

[0023] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0024] The invention provides a technical solution: an antibacterial magnetic knitted fabric dyeing process, comprising the following steps:

[0025] Step 1: Pretreatment, heating the warm water to 80°C, putting the knitted fabric into the hot water, putting acetic acid into the hot water, adjusting the pH value of the hot water to 6-7, electrolyzing the hot water, and Put 0.1g / L magnet particles into the hot water. The magnet particles are crushed and then ground. After the magnet particles are poured into the treatment liquid, they need to be stirred slowly. When stirring, the magnet particles can move with the movement of the water. To the knitted fabric, so that the knitted fabric can be magnetic, and the magnet particles are tiny. When the water is dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com