A fire-resistant, moisture-resistant and high-toughness gel paper and its preparation method

A high-toughness, gel technology, applied in printing, papermaking, and polymer material packaging, can solve the problems of restricting the production and use of polymer paper, poor flexibility of plant fiber paper, poor rigidity of polymer paper, etc., and achieve excellent water storage ability, excellent recovery, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

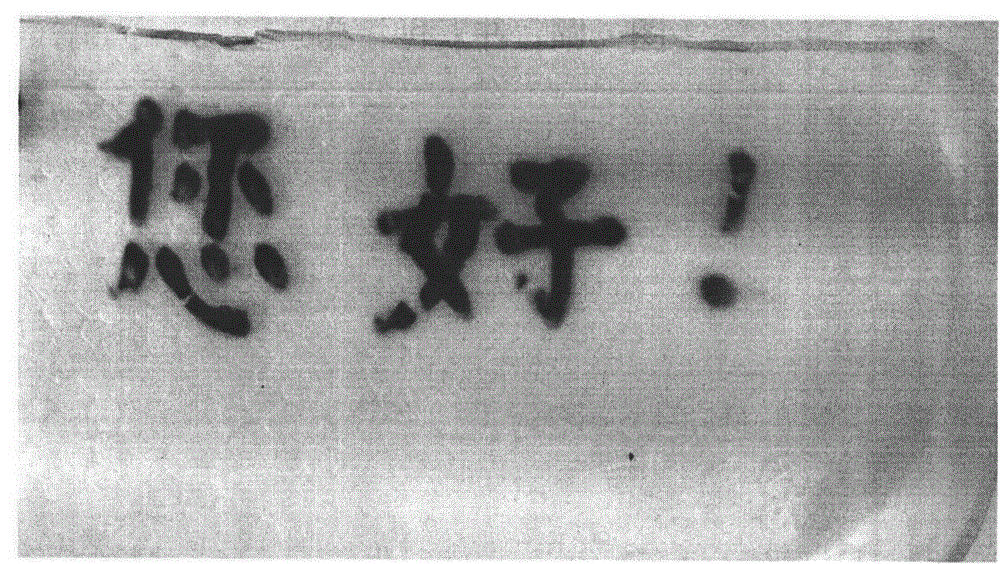

Image

Examples

Embodiment 1

[0039] 1) Preparation of gel pulp prepolymerization solution: Add 3g of acrylamide and 0.3g of sodium alginate into deionized water in sequence at 20°C to prepare a solution with a mass concentration of 11%, and mix and stir for 50 minutes; until a uniform and transparent solution is obtained After the polymer solution, add 0.3g lithium magnesium silicate, 0.05g N, N'-methylenebisacrylamide and 0.03g ammonium persulfate to the system, adjust the temperature to 20°C, and add 0.06g lavender and 0.1 g of calcium sulfate to slowly polymerize the system; when the solution reaches a homogeneous state again, the reaction system is statically defoamed for 30 min; Obtain gel pulp prepolymerization liquid.

[0040] 2) Forming of gel paper: inject the gel pulp pre-polymerized liquid prepared in step 1) into a molding mold with a thickness of 2 mm, a length of 10 cm, and a width of 10 cm at a tangential velocity of 1.4 cm / s. Heat treatment at 45°C for 8 hours to prepare a fire-resistant,...

Embodiment 2

[0043] 1) Preparation of gel pulp pre-polymerization solution: Add 4.5 g of methacrylamide and 0.3 g of polystyrene into deionized water in sequence at 25° C. to prepare a solution with a mass concentration of 13%, and mix and stir for 45 minutes; After obtaining a uniform and transparent polymer solution, add 0.25g hectorite, N,N'-methylenebisacrylamide and 0.045g ammonium persulfate to the system, adjust the temperature to 10°C, and add 0.1g crystal Violet, 0.05g rosemary essential oil and 0.1g glass fiber, make the system slowly polymerize; when the solution reaches a homogeneous state again, degas the reaction system for 20min; Accelerate the polymerization of the system, mix and stir for 8 minutes, and prepare the gel pulp prepolymerization liquid.

[0044] 2) Forming of gel paper: inject the gel pulp pre-polymerized solution prepared in step 1) into a molding mold with a thickness of 1 mm, a length of 25 cm, and a width of 20 cm at a tangential velocity of 1.1 cm / s. Hea...

Embodiment 3

[0047] 1) Preparation of gel pulp pre-polymerization solution: Add 2.4g N-isopropylacrylamide and 0.3g sodium alginate to deionized water in turn at 30°C to prepare a solution with a mass concentration of 12%, and mix and stir for 40min ; After obtaining a uniform and transparent polymer solution, add 0.2g hectorite, 0.1g epichlorohydrin, 0.005g calcium hydrogen sulfate and 0.072g potassium persulfate to the system, adjust the temperature to 5°C, and add 0.1 g amaranth, 0.08g rosemary essential oil and 0.1g calcium sulfate, make the system polymerize slowly; when the solution reaches a homogeneous state again, degas the reaction system for 30min; Amines were used to accelerate the polymerization of the system, and the mixture was mixed and stirred for 15 minutes to obtain a gel pulp prepolymer liquid.

[0048] 2) Forming of gel paper: inject the gel pulp pre-polymerization solution prepared in step 1) into a molding mold with a thickness of 0.5 mm, a length of 20 cm, and a wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com