A post-finishing process for a blended alpaca wool product

A post-finishing and alpaca wool technology, which is applied in the processing of textile materials, textiles and papermaking, and spray/spraying of textile materials. The effect of slow width, easy smoothing, and increased softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

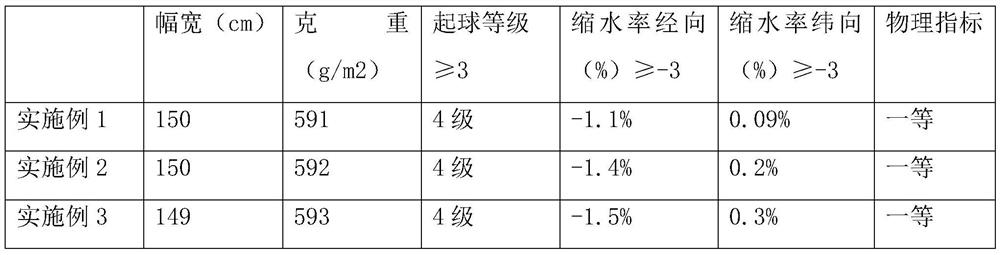

Examples

Embodiment 1

[0038] A finishing process for a blended alpaca product, comprising the steps of:

[0039] S1: The fabric is subjected to airflow adsorption washing in the finishing machine: the airflow adsorption washing is to place the fabric on the drum of the finishing machine, and use the negative pressure airflow in the drum to replace the mechanical pressure to absorb the fabric, and then pass the atomized lotion and water Spray on the surface of the fabric; wherein the water temperature is 40°C, the fabric running speed is 300m / min, the washing time is 20min, the amount of lotion is 4% of the weight of the fabric, and the amount of water added is 22 times the weight of the fabric. The fabric raw materials include 55% mercerized wool, 40% alpaca, and 5% nylon by mass percentage. The above raw materials are spun into five satin fabrics through conventional blending.

[0040] S2: Twice softening: firstly wash and soften the woolen fabric in the washing machine, and then dehydrate the woo...

Embodiment 2

[0050] A finishing process for a blended alpaca product, comprising the steps of:

[0051] S1: The fabric is subjected to airflow adsorption washing in the finishing machine: the airflow adsorption washing is to place the fabric on the drum of the finishing machine, and use the negative pressure airflow in the drum to replace the mechanical pressure to absorb the fabric, and then pass the atomized lotion and water Spray on the surface of the fabric; wherein the water temperature is 50°C, the fabric running speed is 200m / min, the washing time is 20min, the amount of lotion is 3% of the weight of the fabric, and the amount of water added is 18 times the weight of the fabric. The fabric raw materials include 58% mercerized wool, 38% alpaca, and 4% nylon by mass percentage. The above raw materials are spun into five pieces of satin weave fabrics through conventional blending.

[0052] S2: Twice softening: firstly wash and soften the wool in the washing machine, after the washing ...

Embodiment 3

[0062] A finishing process for a blended alpaca product, comprising the steps of:

[0063] S1: The fabric is subjected to airflow adsorption washing in the finishing machine: the airflow adsorption washing is to place the fabric on the drum of the finishing machine, and use the negative pressure airflow in the drum to replace the mechanical pressure to absorb the fabric, and then pass the atomized lotion and water Spray on the surface of the fabric; wherein the water temperature is 45°C, the fabric running speed is 250m / min, the washing time is 20min, the amount of lotion is 3.5% of the weight of the fabric, and the amount of water added is 20 times the weight of the fabric. The fabric raw materials include 60% mercerized wool, 35% alpaca, and 5% nylon by mass percentage. The above raw materials are spun into five pieces of satin weave fabrics through conventional blending.

[0064] S2: Twice softening: firstly wash and soften the wool in the washing machine, after the washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com