Spraying device for green and environment-friendly coating and using method of spraying device

A green and environmental protection spraying device technology, which is applied to the surface coating liquid device, spraying device, liquid spraying device, etc., can solve the time-consuming and labor-intensive problems, save costs, improve the spraying effect, improve the use effect and applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

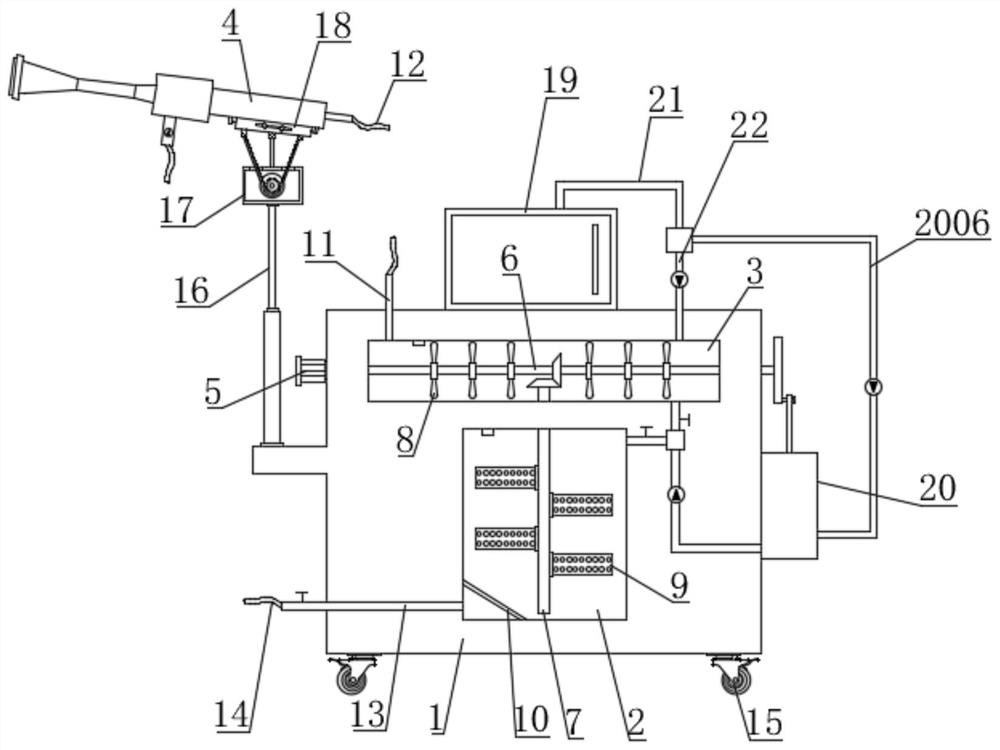

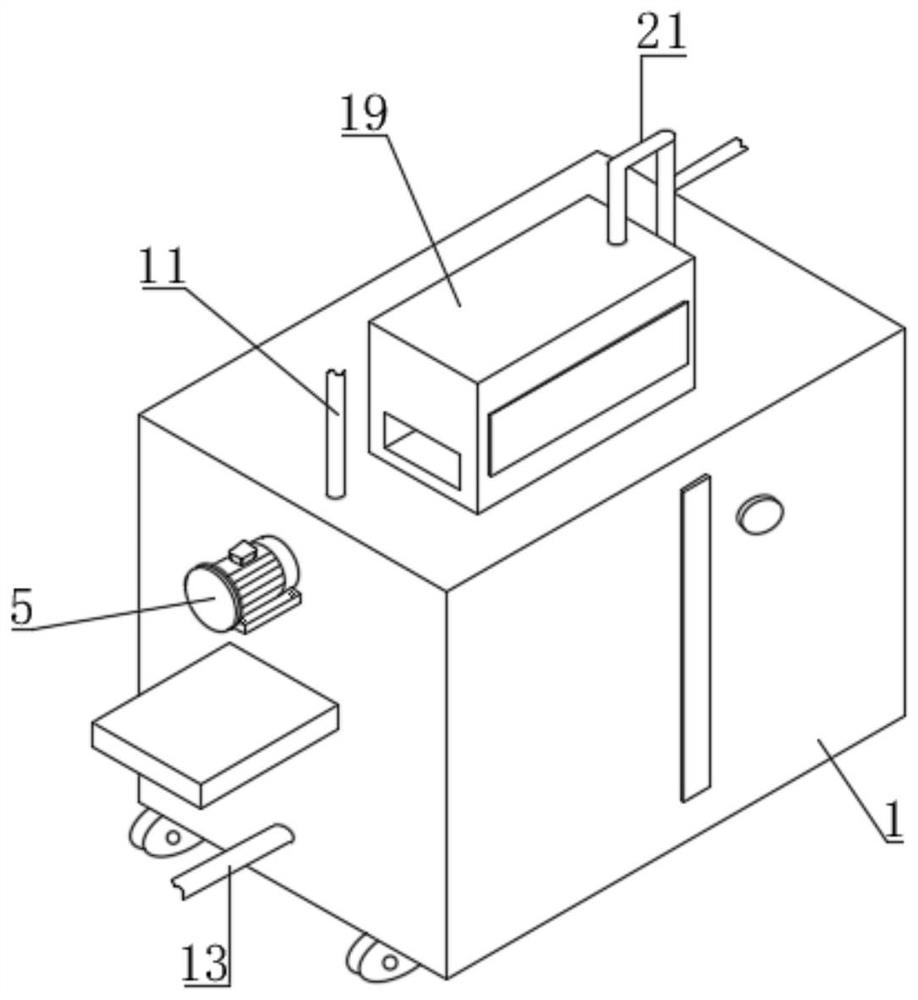

[0048] Such as Figure 1-7 As shown, a kind of spraying device that the present invention proposes is used for green environmental protection paint, comprises fixed box 1, material storage chamber 2, spraying assembly 4 and walking wheel 15, and the bottom of fixed box 1 is equipped with many groups of walking wheels 15, and walking The arrangement of wheels 15 is helpful for the movement and transportation of the device, and a material storage chamber 2 is provided in the fixed box 1, and paint is stored in the material storage chamber 2, and a blast chamber 3 is provided in the fixed box 1, and the fixed box 1 passes through A first motor 5 is fixedly installed on the motor base, and an air guide shaft 6 is installed on the output end of the first motor 5, and the first motor 5 is used to drive the air guide shaft 6, and the air guide shaft 6 is horizontally arranged in the blast cavity 3, There are multiple groups of blower blades 8 installed on the air guide shaft 6, and t...

Embodiment 2

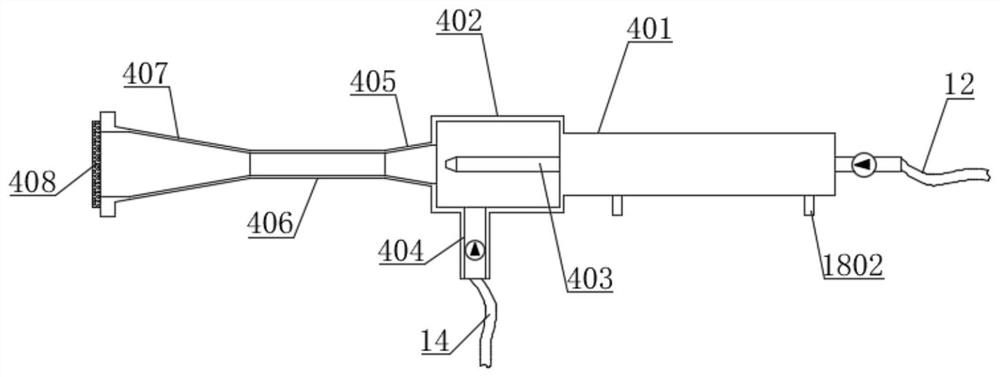

[0052] Such as Figure 8-9As shown, the difference between this embodiment and Embodiment 1 is that the lifting rod 16 is fixedly installed on the fixed box 1 through the mounting seat, the lifting rod 16 is an electric telescopic rod, and the top of the lifting rod 16 is provided with an inclination angle adjustment assembly 17, and The inclination angle adjustment assembly 17 acts on the spraying assembly 4. When spraying, adjust the height of the spraying assembly 4 according to the actual situation and through the elevating rod 16, so as to adapt to the spraying operation at different height positions; the inclination angle adjustment assembly 17 includes a connection Box 1701, second motor 1702, gear 1703, rack belt 1704, support rod 1705 and connecting shaft 1706, connecting box 1701 is connected with the top of elevating rod 16, and the inside of connecting box 1701 is fixedly installed with second motor 1702 through the motor seat , the output end of the second motor 1...

Embodiment 3

[0054] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the inclination angle adjustment assembly 17 and the spraying assembly 4 are connected through the installation assembly 18, and the installation assembly 18 includes a fixed plate 1801, a fixed block 1802, an insertion rod 1803, Fixed groove 1804, limit guide groove 1805, limit slider 1806, connecting block 1807, connecting rod 1808 and spring 1809, fixed plate 1801 is positioned at the top of connecting box 1701, and the top of support rod 1705 is connected with fixed plate 1801, and the tooth Both ends of the strip 1704 are connected to the top sides of the fixed plate 1801; the bottom of the spraying assembly 4 is symmetrically provided with fixed blocks 1802, the fixed plate 1801 is located between two sets of fixed blocks 1802, and the fixed block 1802 faces one side of the fixed plate 1801 A fixed groove 1804 is provided, and a limit guide groove 1805 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com