Automatic impregnation system for wave-absorbing honeycombs

A honeycomb and dipping technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of incapable of honeycomb processing, each process cannot be carried out together, and transporting takes a lot of time, saving space, dipping, etc. Good glue effect and quick dipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

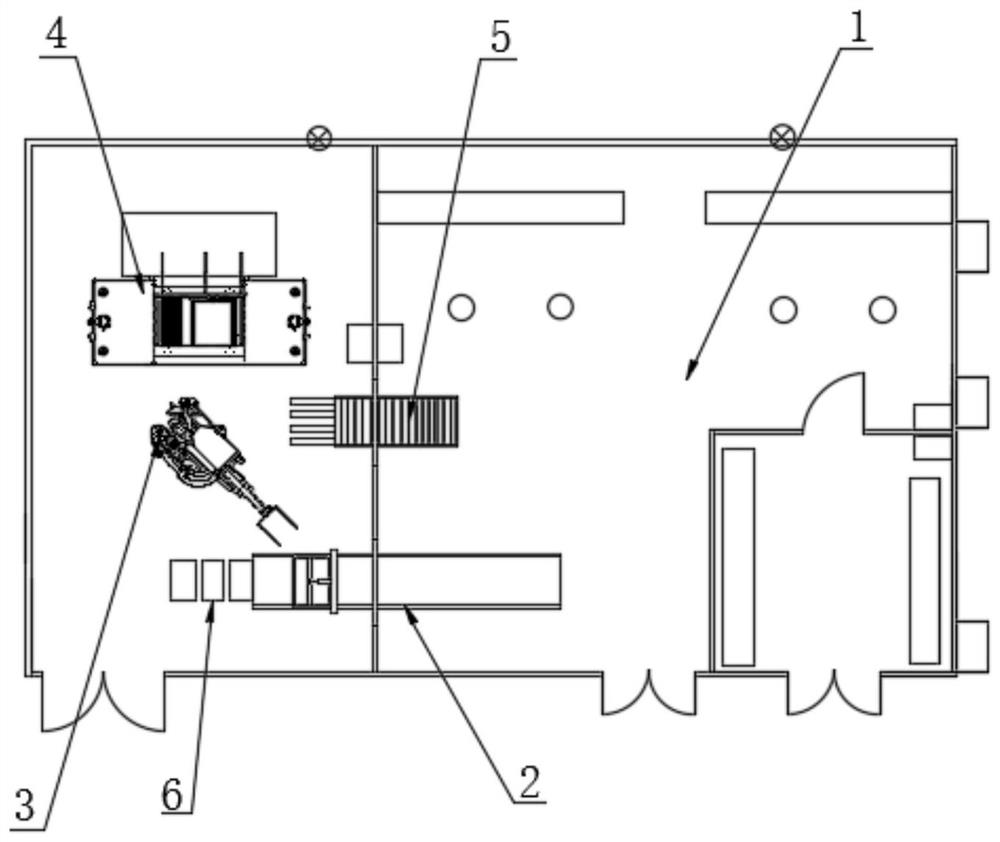

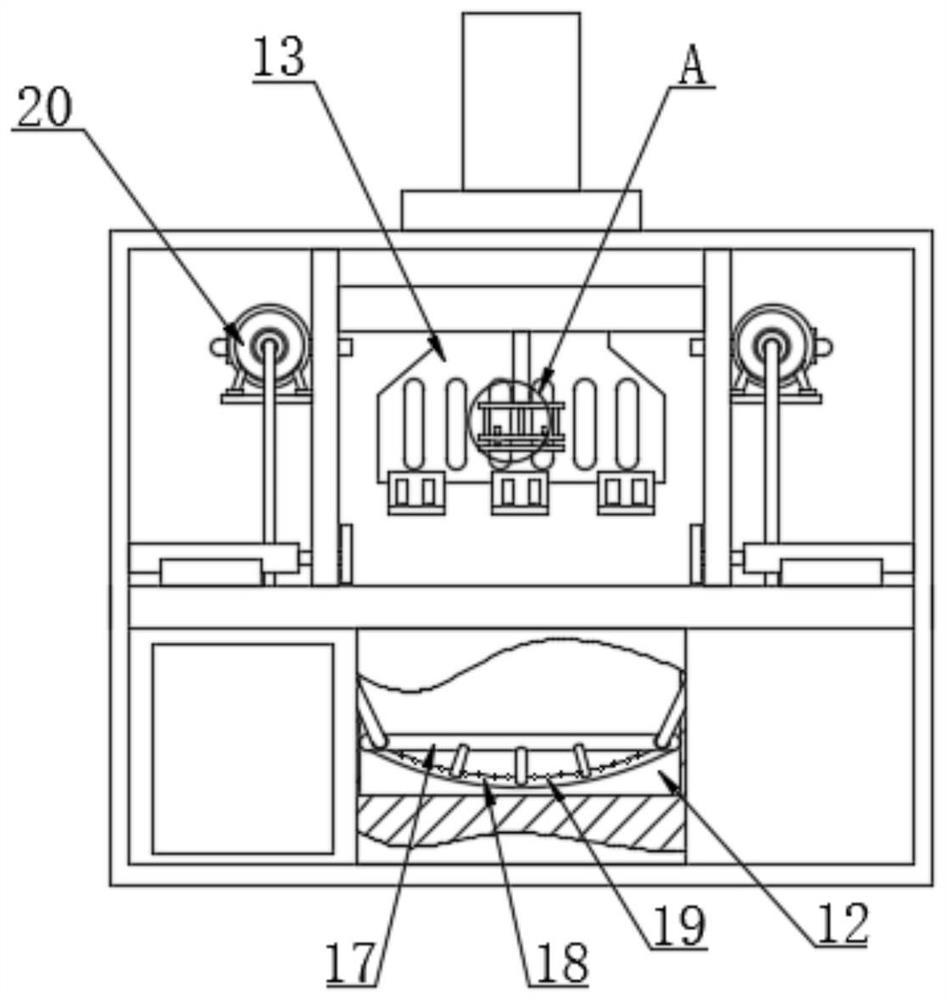

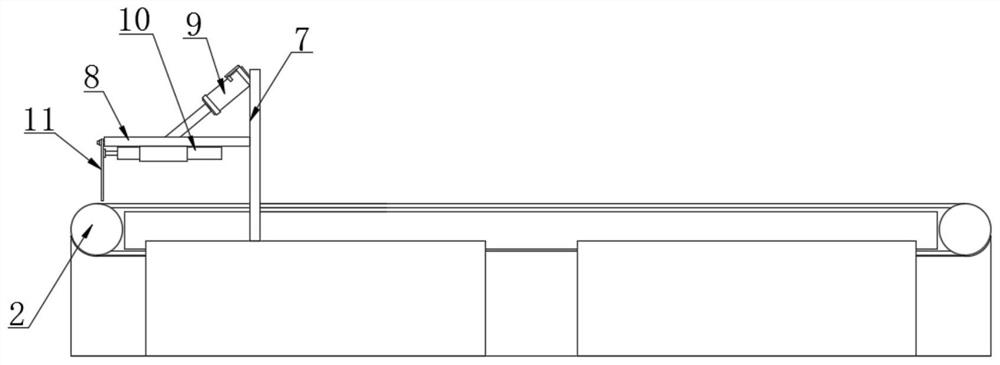

[0027] see Figure 1-6 , the present invention provides a technical solution: a wave-absorbing cellular automatic dipping system, including a dipping room and a drying room 1, and the dipping room is respectively provided with a feeding conveyor belt 2, an automatic robot 3, a dipping device 4 and an outlet Material conveyer belt 5, feed conveyer belt 2 and discharge conveyer belt 5 all extend to airing room 1, and one end of feed conveyer belt 2 is connected with the feeding table 6 that is used to place honeycomb, and automatic robot 3 is used for honeycomb from The loading platform 6 is transported into the dipping device 4, the dipping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com