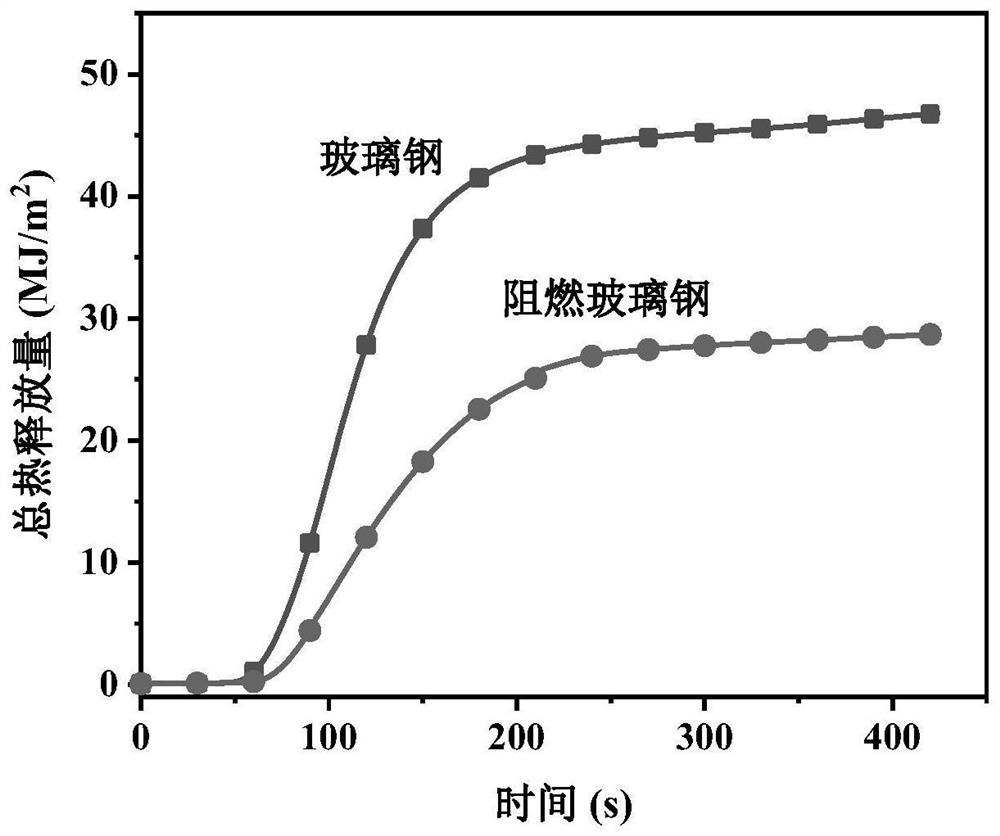

Cellulose nanocrystal/MXene self-assembled flame-retardant antistatic coating and application in glass fiber reinforced plastic

A flame-retardant, anti-static, nano-crystal technology, applied in the direction of cellulose coatings, coatings, conductive coatings, etc., can solve the problems of economic loss, poor flame retardancy of FRP, threats to human life safety, etc., to achieve improved flame retardancy, high Conductive, highly reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of flame retardant dispersion:

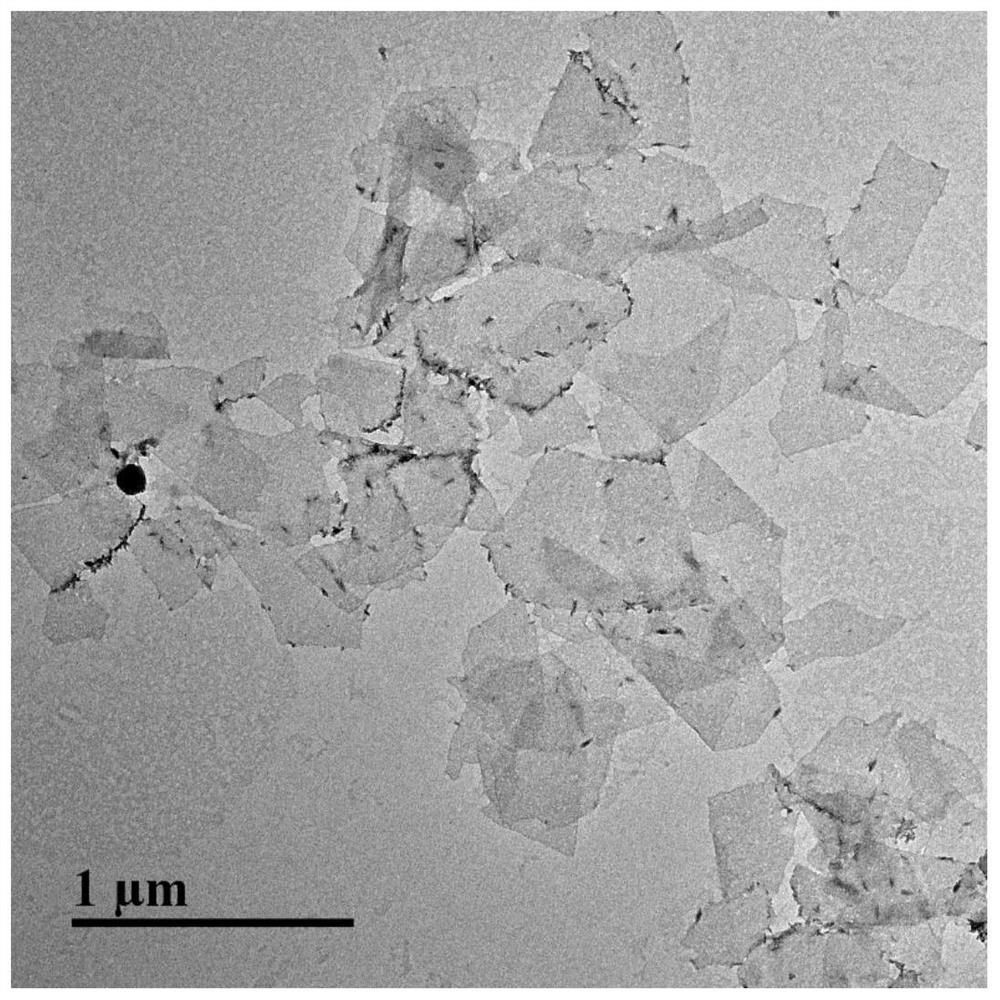

[0036] Add 2g lithium fluoride to 40ml 9M hydrochloric acid, react at room temperature for 30min, raise the temperature to 35°C, add 2gTi 3 AlC 2 , reacted for 24h, centrifuged, collected the solid, washed with water and dried to obtain Ti 3 C 2 T x colloid.

[0037] Dissolve 0.1 g of tannic acid in 300 ml of deionized water, and add 0.2 g of Ti to the solution 3 C 2 T x The colloid was ultrasonically dispersed for 2 hours, centrifuged to collect the solid, washed with water, dried, and re-dispersed to obtain 2 mg / mL Ti 3 C 2 T x nanosheet dispersion;

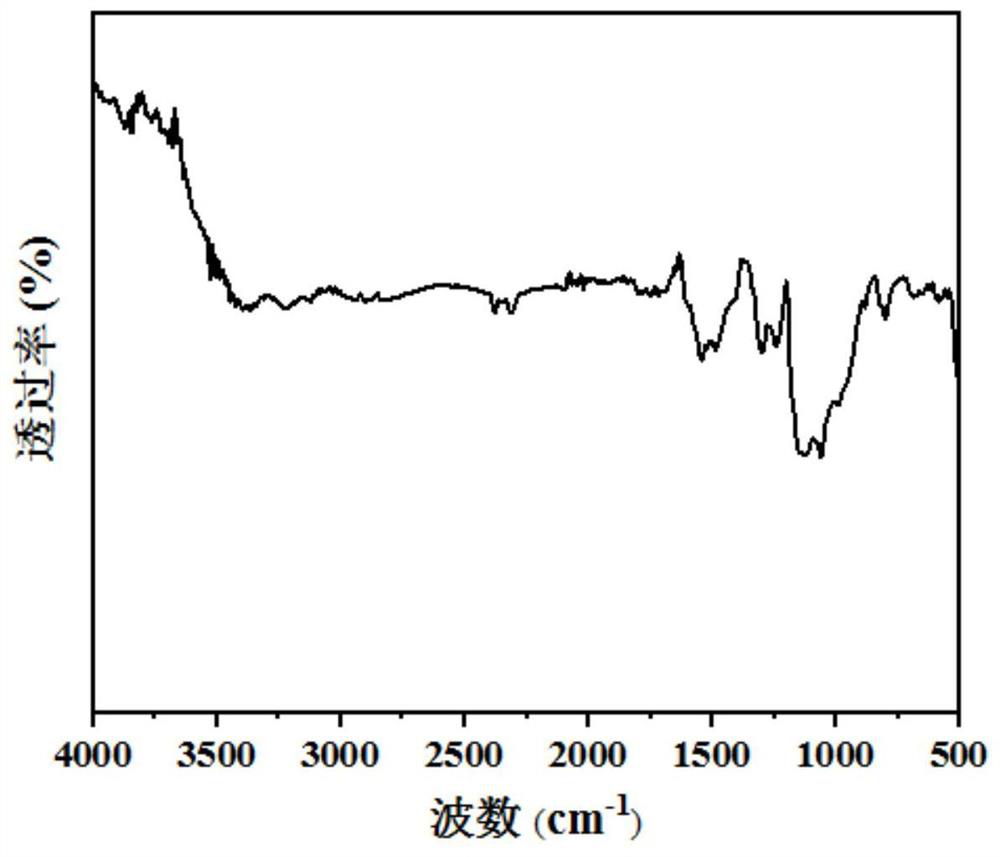

[0038] Dissolve 1 g of aniline monomer in 200 ml of deionized water, then add 0.5 g of phytic acid and 0.3 g of cellulose nanocrystals to the aniline solution, and after ultrasonication in a water bath for 1 h, add 0.15 g of ammonium persulfate to the mixture and react at 0 °C 3h, washed with water, dried and re-dispersed to obtain a flame-retardant cellulose nanocr...

Embodiment 2

[0045] Preparation of flame retardant dispersion:

[0046] Add 2g lithium fluoride to 40ml 9M hydrochloric acid, react at room temperature for 30min, raise the temperature to 35°C, add 2gTi 3 AlC 2 , reacted for 24h, centrifuged, collected the solid, washed with water and dried to obtain Ti 3 C 2 T x colloid.

[0047] Dissolve 0.1 g of tannic acid in 300 ml of deionized water, and add 0.2 g of Ti to the solution 3 C 2 T x The colloid was ultrasonically dispersed for 2 hours, centrifuged to collect the solid, washed with water, dried, and re-dispersed to obtain 2 mg / ml Ti 3 C 2 T x nanosheet dispersion;

[0048] Dissolve 1 g of aniline monomer in 200 ml of deionized water, then add 0.8 g of phytic acid and 0.3 g of cellulose nanocrystals to the aniline solution, and after ultrasonication in a water bath for 1 h, add 0.15 g of ammonium persulfate to the mixture, and Reacted for 3 hours, washed with water, dried and re-dispersed to obtain a flame-retardant cellulose na...

Embodiment 3

[0051] Preparation of flame retardant dispersion:

[0052] Add 2g lithium fluoride to 40ml 9M hydrochloric acid, react at room temperature for 30min, raise the temperature to 35°C, add 2gTi 3 AlC 2 , reacted for 24h, centrifuged, collected the solid, washed with water and dried to obtain Ti 3 C 2 T x colloid.

[0053] Dissolve 0.1 g of tannic acid in 300 ml of deionized water, and add 0.2 g of Ti to the solution 3 C 2 T x The colloid was ultrasonically dispersed for 2 hours, centrifuged to collect the solid, washed with water, dried, and re-dispersed to obtain 3 mg / mL Ti 3 C 2 T x nanosheet dispersion;

[0054] Dissolve 1 g of aniline monomer in 200 ml of deionized water, then add 0.5 g of phytic acid and 0.3 g of cellulose nanocrystals to the aniline solution, and after ultrasonication in a water bath for 1 h, add 0.15 g of ammonium persulfate to the mixture, and Reacted for 3 hours, washed with water, dried and re-dispersed to obtain a flame-retardant cellulose na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com