Uniform step jump control method and steel wire ring winding method and system

A control method and a traveler technology, which is applied in the field of tire production and processing, can solve problems such as the influence of the overall dynamic balance of the tire, and achieve the effects of reducing influence, reducing calculation and debugging time, and reducing width and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

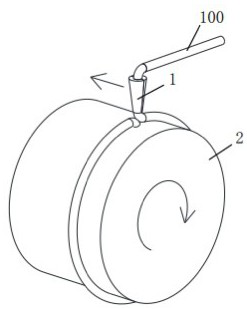

[0047] The invention provides a bead ring winding method, which is realized by a bead ring winding system. The traveler winding system includes:

[0048] winding wheel;

[0049] The motor is used to drive the winding wheel to rotate;

[0050] guide wire head;

[0051] The wire guide head driving arm is used to drive the wire guide head to move laterally for horizontal wire arrangement, and to drive the wire guide head to move vertically for vertical jumping;

[0052] The control system is used to control the action of the motor and the wire guide head driving arm.

[0053] The traveler winding method comprises the following steps:

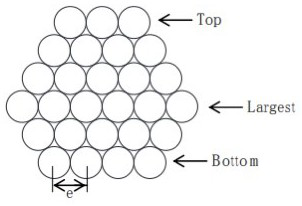

[0054] First, calculate the total number of layers f and the total number of turns g of the traveler according to the bottom layer of the traveler, the layer with the largest number of turns in the middle, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com