Polishing pad and manufacturing method of semiconductor device

A manufacturing method and polishing pad technology, applied in the field of polishing pads, can solve problems such as lack of in-depth research, influence on the manufacturing process of semiconductor devices, insufficient research, etc., and achieve excellent polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0076] Embodiment

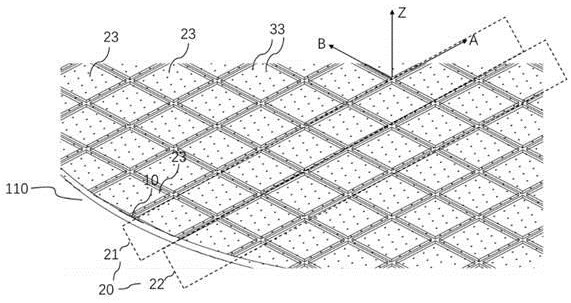

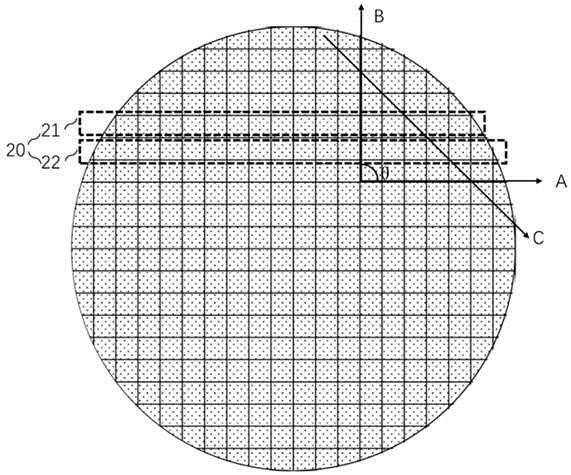

[0077] figure 1 It is an exemplary display according to a polishing pad of a polishing pad according to an embodiment of the present invention, a plan view of a polishing pad. figure 2 . In order to make it easy to explain, figure 1 The first direction is referred to as a direction, and the second direction is referred to as a B direction, and the third direction is referred to as a C direction, and the polishing pad thickness direction, that is, the direction perpendicular to the surface of the polishing pad is referred to as the Z direction.

[0078] In an embodiment, the direction A direction is 90 degrees in the direction, i.e., SIN θ is 1. Refer figure 1 The polishing pad of the present invention is suitable for polishing or planating at least one of a semiconductor, an optical, and a magnetic substrate. The polishing layer 110 has a polishing surface 10 and a polishing unit group 20, and the polishing unit group 20 is distributed over the polishing surfa...

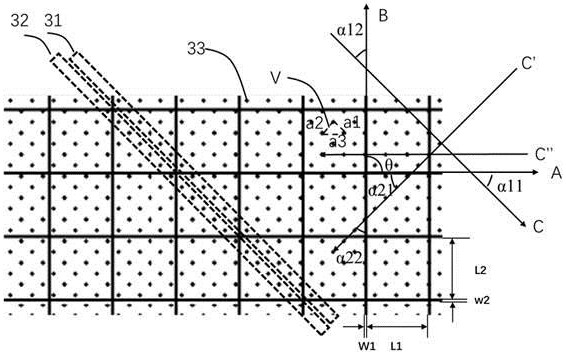

Example Embodiment

[0114] According to an embodiment of the present invention, the first direction is 90 ° in the second direction; the third direction is not α1 with an angle in the first direction, the α1 The range is 10 ° ≤ α1 ≤ 45 °; and / or, the third direction is α2 in the third direction to the second direction, and the α2 has a range of 10 ° ≤ α2 ≤ 45 °.

[0115] As a more preferred embodiment of the present invention, the first direction is 90 ° in the first direction, 90 °; the third direction is α1 in the third direction and the first direction is α1, said The α1 ranges from 10 ° ≤ α1 ≤ 20 °; and / or the third direction is α2 with the upper portion of the second direction, and the α2 ranges from 10 ° ≤ α2 ≤ 20 °.

[0116] An embodiment of the present invention discloses the center of a pit of the first pit set and a triangular V. More preferably, equilateral triangles.

[0117] More preferably, the triangular V is an equilateral triangle, and the angle θ of the first direction is 90 ° i...

Example Embodiment

[0118] Embodiment 2

[0119] Similar to the embodiment, the direction in the second embodiment is 90 degrees in the direction in the direction, i.e., SIN θ is 1. Similarly, the three-dimensional structure of the independent polishing unit can be referenced figure 1 The polishing layer has a polishing surface and a polishing unit group, and the polishing unit group is distributed on the polishing surface, and the surface of the polishing unit group is directly in contact with the abrasive material.

[0120] Reference style of polishing unit of polishing layer Figure 9 The first portion 41 and the second portion 42 of the second portion 42 are interleaved distribution. Preferably, the disturbed distance is half the edge length of the grinding unit in the A direction.

[0121] This embodiment is one of the preferred embodiments of the present invention, similarly, and evenly distributed pits 53, the size of the polishing unit, the shape, size, and size of the pits are as defined as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com