Preparation method of nano-SiO2 polishing solution

A kind of polishing liquid and nanotechnology, applied in the direction of polishing composition containing abrasives, etc., can solve the problems of surface quality to be improved, low production efficiency, low polishing rate, etc., and achieve excellent polishing performance and no corrosion pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

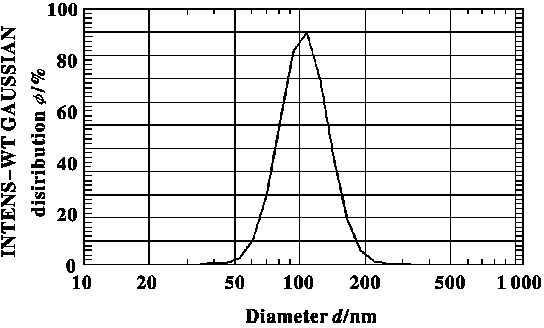

[0013] (1) Dissolve water glass in deionized water first, then heat to obtain 5nm SiO 2 seed crystals, and then make the nano-SiO 2 The particles grow up to 110nm, followed by ultrafiltration and concentration to obtain nano-SiO 2 colloid;

[0014] (2) To nano-SiO 2 Add stabilizer, polishing regulator, and pH regulator to the colloid in turn, add deionized water to keep the solid content at 40%, stir evenly, and then filter to obtain the filtrate.

[0015] (3) Polishing is performed at a pressure of 39.2kPa, a rotational speed of 60r / min, a flow rate of polishing fluid of 1L / min, and a polishing time of 4h.

[0016] (4) The measured average polishing rate is 5.2 μm / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com