Energy-saving air cleaning system applied to elevator

An air cleaning and elevator technology, which is applied in the field of elevator air cleaning, can solve the problems of being unable to reduce energy consumption, etc., and achieve the effects of reducing the installation of filter carrier plates, easy maintenance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

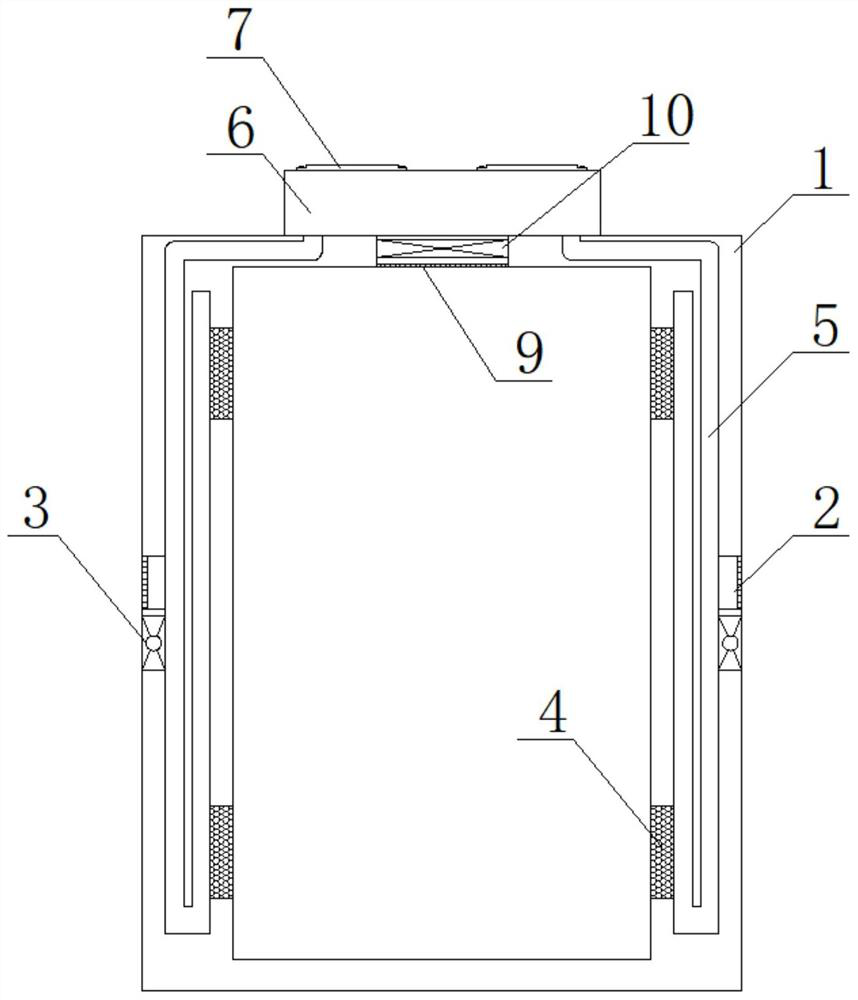

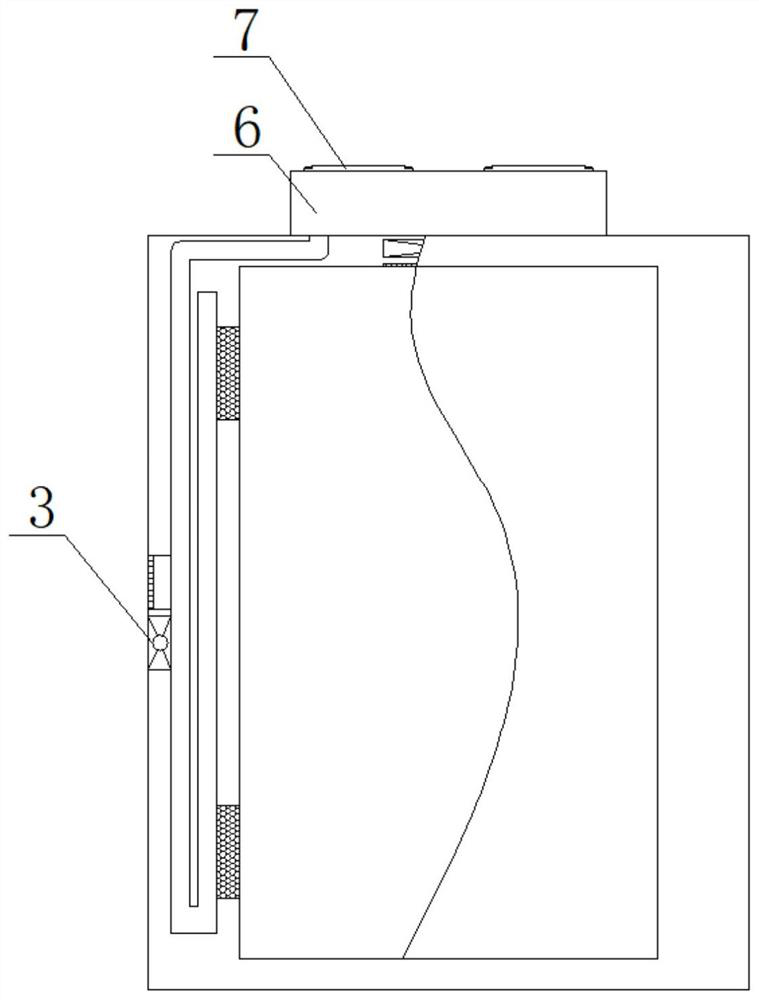

[0025] refer to Figure 1-5 , an energy-saving air cleaning system applied to elevators, comprising an elevator car body 1, characterized in that, the two sides of the elevator car body 1 are respectively provided with air inlets 2, and the air inlets 2 are provided with two There are two air outlets 3 below the air inlet 2, two air inlets 2 are also provided, and four air circulation outlets 4 are arranged inside the elevator car body 1.

Embodiment 2

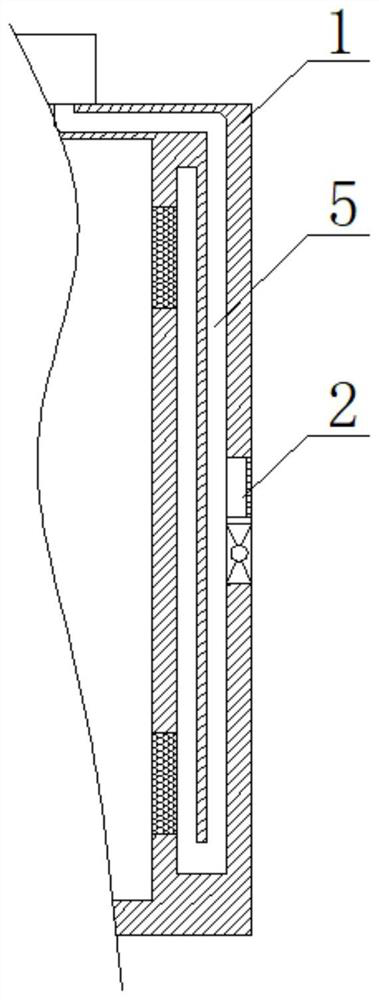

[0027] Both ends of the filter carrier plate 71 are fixed on the outer upper surface of the air treatment purification box 6 by bolts. A plurality of snap-in slots 73 are provided below the filter carrier plate 71. The snap-in slots 73 are in the shape of an arrow as a whole. Groove 73 clamps and embeds snap-in terminal 74, and there is the space of five centimeters at least between each air filter plate 75, and the upper end of air filter plate 75 links to each other with snap-in terminal 74, and the lower end of air filter plate 75 and air pass through The bottom surface of the chamber 8 is in contact, and the filter carrier plate 71 is in contact with the sealing rubber layer 72 through the sealing rubber layer 72 .

[0028] Working principle: elevator car body 1, air inlet 2, air outlet 3, air circulation port 4, air circulation chamber 5, air treatment purification box 6, air purification assembly 7, filter carrier plate 71, sealing rubber layer 72, Engagement slot 73, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com