Preparation and degradation method of a thermosetting epoxy resin that can be degraded by gamma ray irradiation

An epoxy resin and γ-ray technology, applied in the preparation of sulfide, organic chemistry, plastic recycling, etc., can solve the problems of difficulty in taking into account excellent performance and degradation performance, and harsh conditions for degradation methods, and achieve super penetrating, The effect of low cost and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

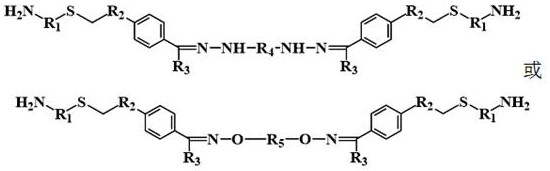

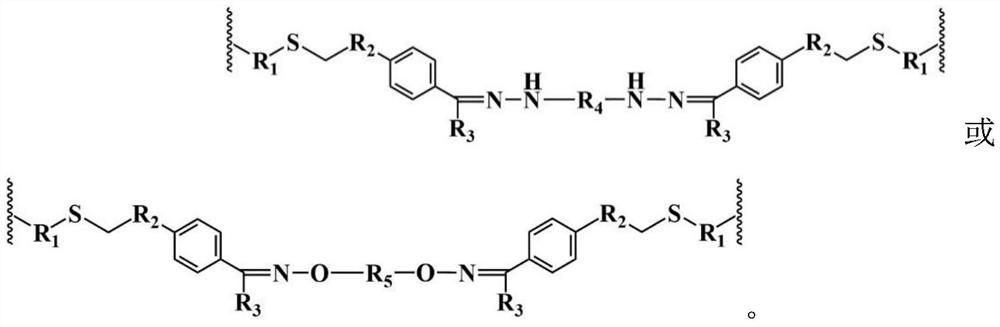

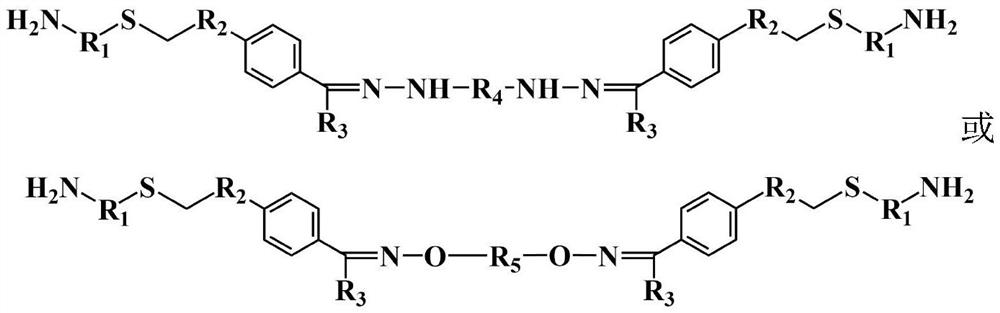

[0026] Embodiment 1: the preparation of curing agent 1

[0027]

[0028] Curing agent Ι

[0029] In 500mLTHF, add 12.51g of p-aminothiophenol, 13.21g of 4-vinylbenzaldehyde and 1mol% of 2,2-dimethoxy-2-phenylacetophenone (DMPA), after the dissolution is complete, the The mixed solution was irradiated under a 365 nm ultraviolet lamp, stirred at room temperature for 60 min, and then the solvent was removed in vacuo to obtain a crude product. 32.13g of the crude product and 19.14g of isophthalic acid dihydrazide were dissolved in methanol, and after reacting at 50°C for 5h, a white precipitate precipitated out. The precipitate was washed three times successively with water, methanol and water, and dried in vacuum to obtain pure curing agent 1 with a yield of 70%.

[0030] 1 H-NMR(d-DMSO):11.58(s,2H),8.50(s,1H),7.75(m,4H),7.31(m,6H),6.67(d,2H),5.50(s,4H) ,3.12(m,4H),2.95(m,4H)

Embodiment 2

[0031] Embodiment 2: the preparation of curing agent II

[0032]

[0033] Curing agent Ⅱ

[0034] In 500mLTHF, add 12.51g of p-aminothiophenol, 13.21g of 4-vinylbenzaldehyde and 1mol% of 2,2-dimethoxy-2-phenylacetophenone (DMPA), after the dissolution is complete, the The mixed solution was irradiated under a 365 nm ultraviolet lamp, stirred at room temperature for 60 min, and then the solvent was removed in vacuo to obtain a crude product. Take 32.13g of the crude product and 17.42g of adipic acid dihydrazide and dissolve them in water. After reacting at 50°C for 5h, a white precipitate precipitates out. The precipitate was washed three times successively with water, methanol and water, and the pure curing agent II was obtained after vacuum drying with a yield of 72%.

[0035] 1 H-NMR(d-DMSO):11.07(s,2H),8.47(s,2H),7.82(d,4H),7.35(m,8H),6.67(m,4H),5.49(s,4H) ,3.12(m,4H),2.95(m,4H),2.34(m,4H),1.53(m,4H)

Embodiment 3

[0036] Embodiment 3: the preparation of curing agent III

[0037]

[0038] Curing agent Ⅲ

[0039] In 500mLTHF, add 12.51g of p-aminothiophenol, 13.21g of 4-vinylbenzaldehyde and 1mol% of 2,2-dimethoxy-2-phenylacetophenone (DMPA), after the dissolution is complete, the The mixed solution was irradiated under a 365 nm ultraviolet lamp, stirred at room temperature for 60 min, and then the solvent was removed in vacuo to obtain a crude product. Take 32.13g of the crude product and 18.46g of O,O'-1,3-propanediylbishydroxylamine dihydrochloride and dissolve them in water. After reacting at 50°C for 5h, a white precipitate precipitates out. The precipitate was washed three times successively with water, ethanol and water, and dried in vacuum to obtain pure curing agent III with a yield of 72%.

[0040] 1 H-NMR(d-DMSO):8.44(s,2H),7.82(d,4H),7.38(m,4H),6.67(m,4H),5.20(s,4H),3.51(m,4H) ,3.12(m,4H),2.95(m,4H),1.79(m,4H)

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com