Thread guiding mechanism of textile equipment for cotton cloth processing and using method of thread guiding mechanism

A technology of textile equipment and wire, applied in the field of wire mechanism of textile equipment for cotton fabric processing, can solve the problems such as difficulty in removing dust on the outer surface of the spinning thread, unobservable adjustment of the tensioning force of the spinning thread, and difficult wet work, etc. Fractures, reduced mechanical wear and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

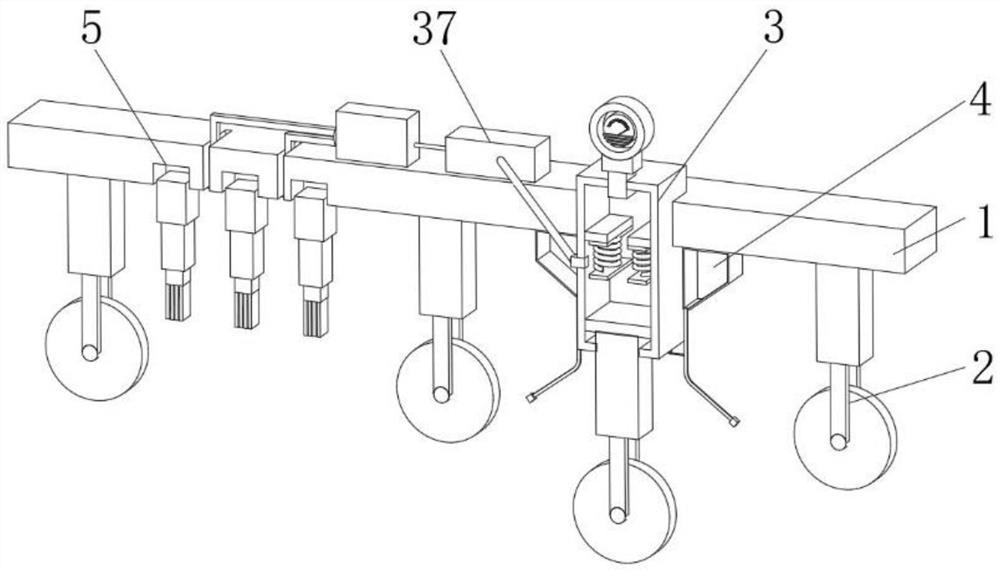

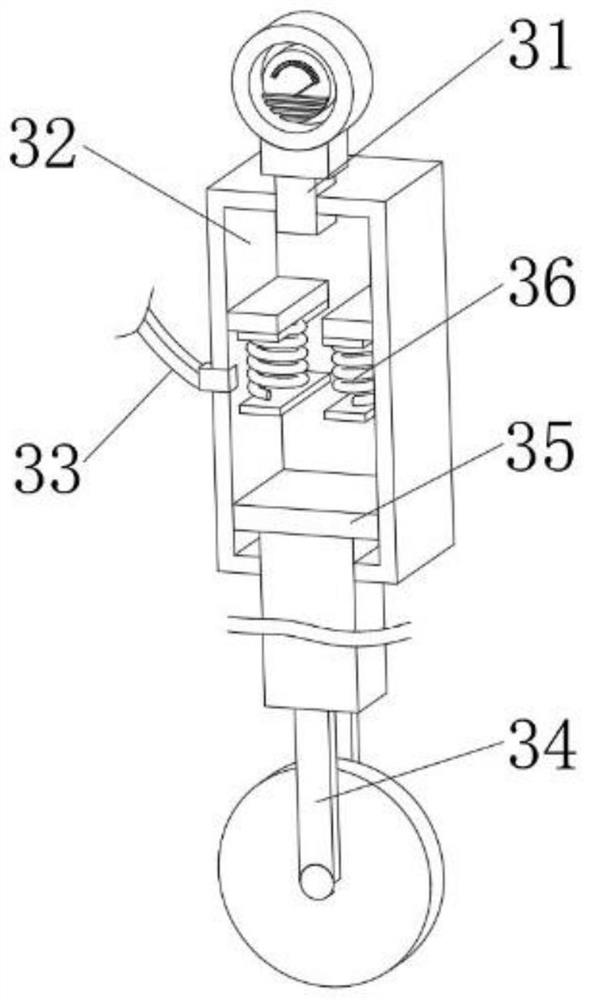

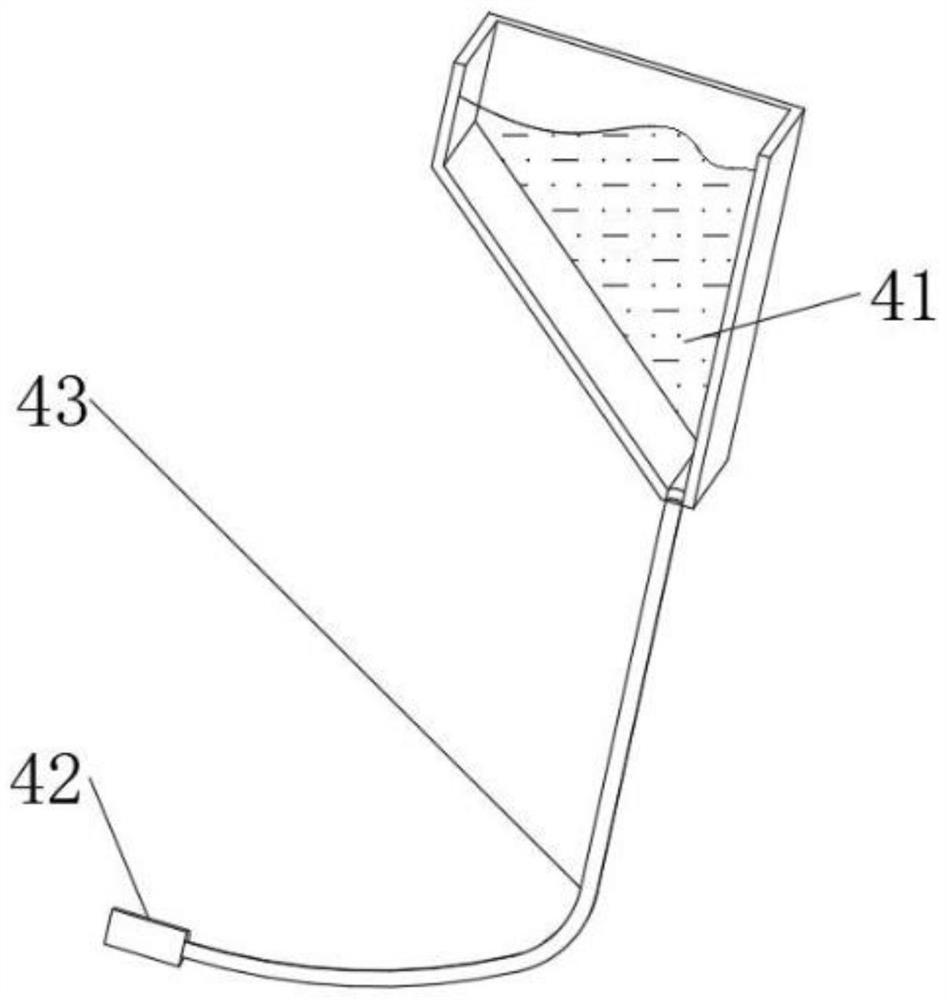

[0034] as attached figure 1 to the attached Figure 7 An embodiment of the present invention provides a wire mechanism for textile equipment for cotton cloth processing, which includes a mounting rod 1, a wire pulley 2 is fixedly installed on the bottom surface of the mounting rod 1, and an air pressure tensioning mechanism 3 is fixedly mounted on the inside of the mounting rod 1. The thread running mechanism 4 is slidably connected with a reciprocating dust removal mechanism 5 on the bottom surface of the mounting rod 1, and the air pressure tensioning mechanism 3 includes a sealed air pressure box 32, and the inner cavity of the sealed air pressure box 32 is slidably connected with a sliding connecting plate 35, and the sliding connecting plate 35 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com