Heat exchange structure and heat exchange integrated device and engine oil heat exchange system

A technology of heat exchange structure and engine block, which is applied in the direction of engine lubrication, engine components, machines/engines, etc. It can solve the problems that the heat exchange performance is difficult to meet the heat dissipation requirements, etc., and achieve the effect of sufficient heat exchange and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

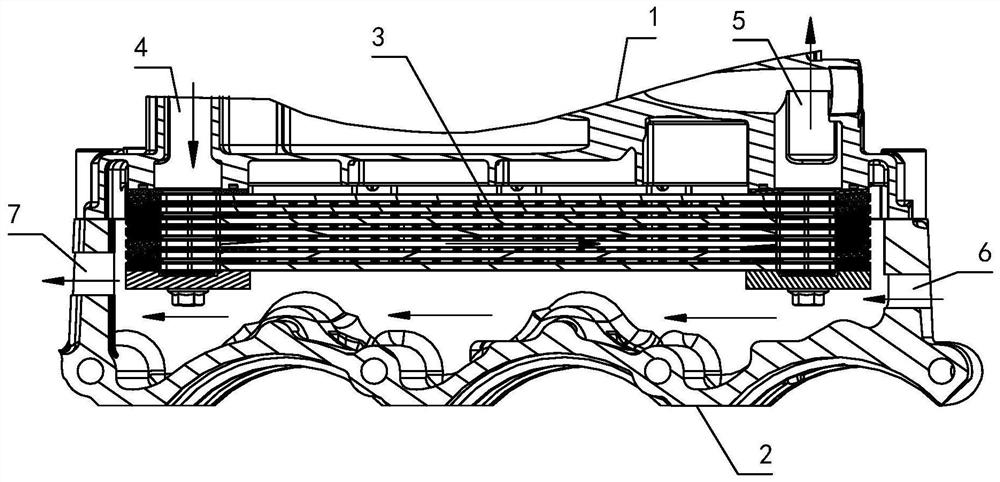

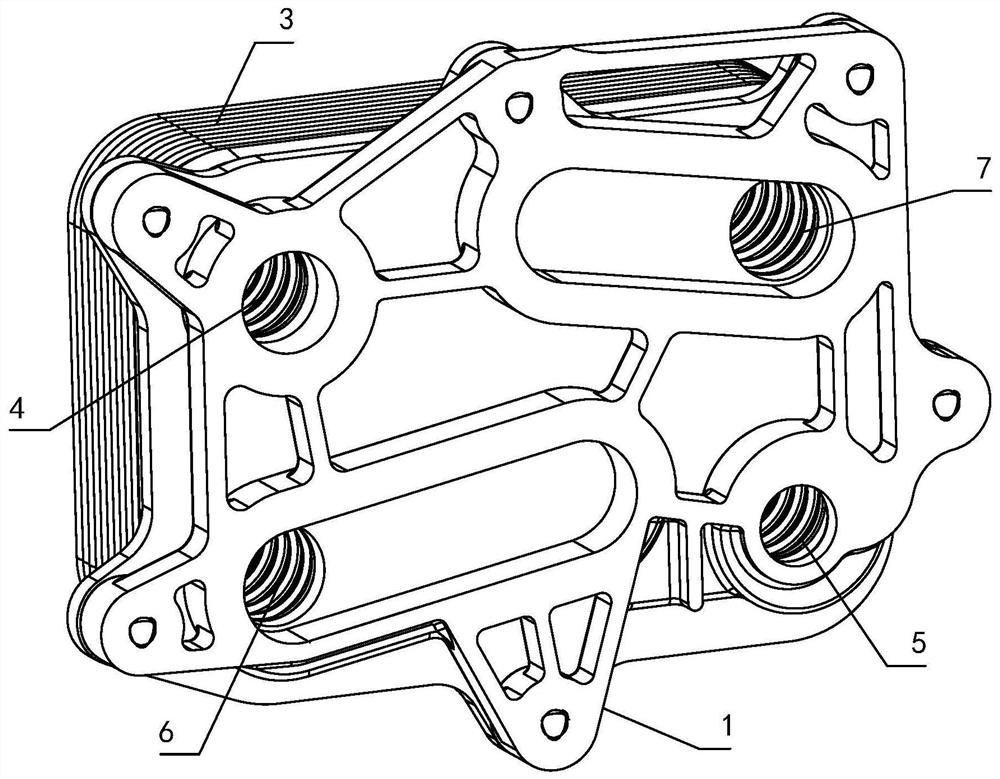

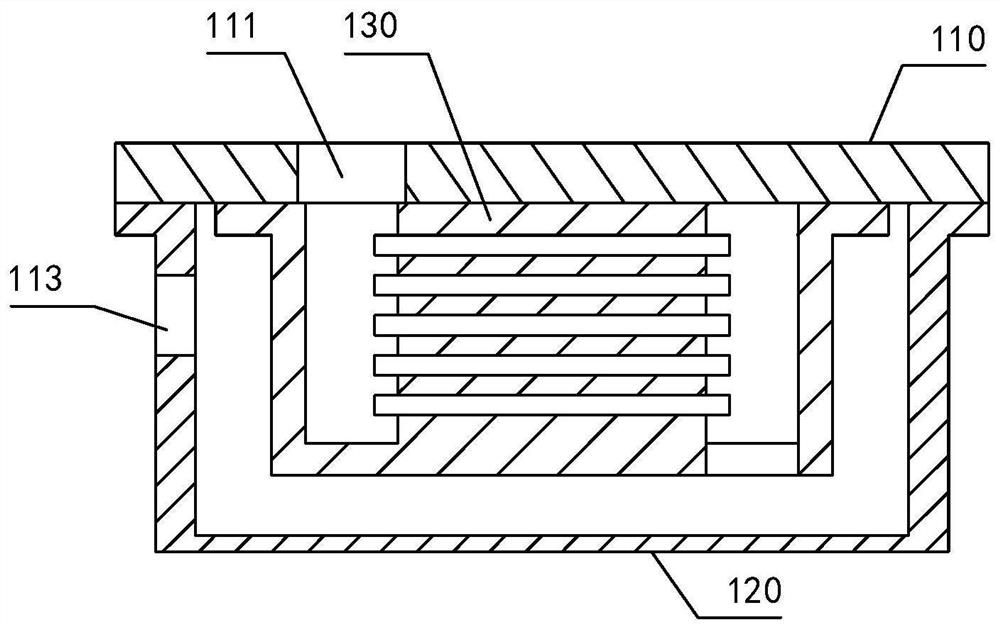

[0056] This embodiment provides a heat exchange structure, an integrated heat exchange device, and an engine oil heat exchange system. Please refer to Figure 3-1 to Figure 6-4 , Figure 3-1 to Figure 3-3 Three schematic structural diagrams of the heat exchange structure provided in this embodiment, wherein, Figure 3-1 The connection shell shown is not provided with the heat exchange outer channel outlet, Figure 3-2 and Figure 3-3 The connection shell shown is provided with a heat exchange outer channel outlet, Figure 3-3 The number of heat exchangers shown is 2. In order to facilitate the display of the structure, Figure 3-1 to Figure 3-3 Only the flow channels through which the heat exchange medium flows are shown, and the flow channels through which the raw liquid flows are not shown; Figure 3-2 The arrow direction shown is the flow direction of the heat exchange medium. Figure 4 The principle diagram of the heat exchange integrated device provided in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com