A low-temperature condensate treatment process and device for a deoiling and dehydrating device in a natural gas treatment plant

A technology of dehydration device and treatment device, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problem that the discharged mixed gas cannot meet the requirements of the hydrocarbon dew point of the fuel gas, and achieve significant energy saving effect, reduce heat load, and reduce investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

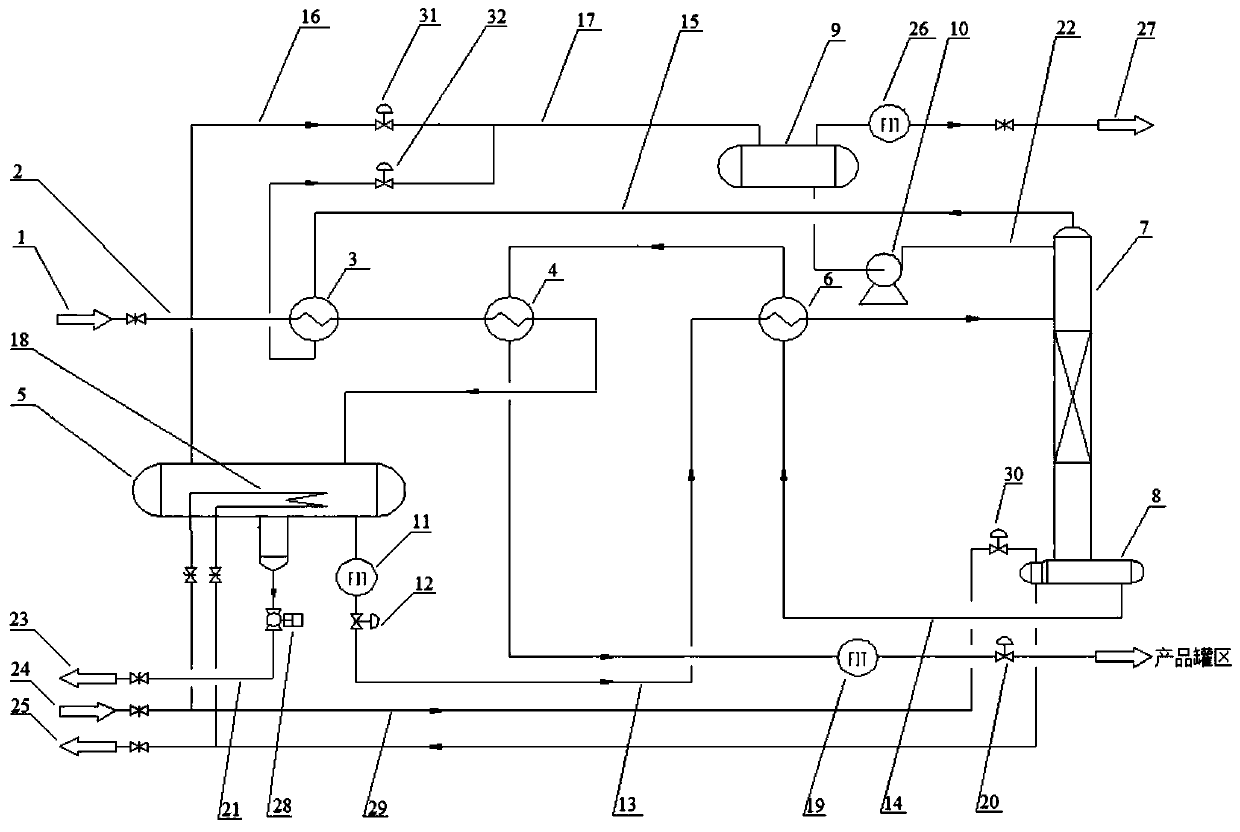

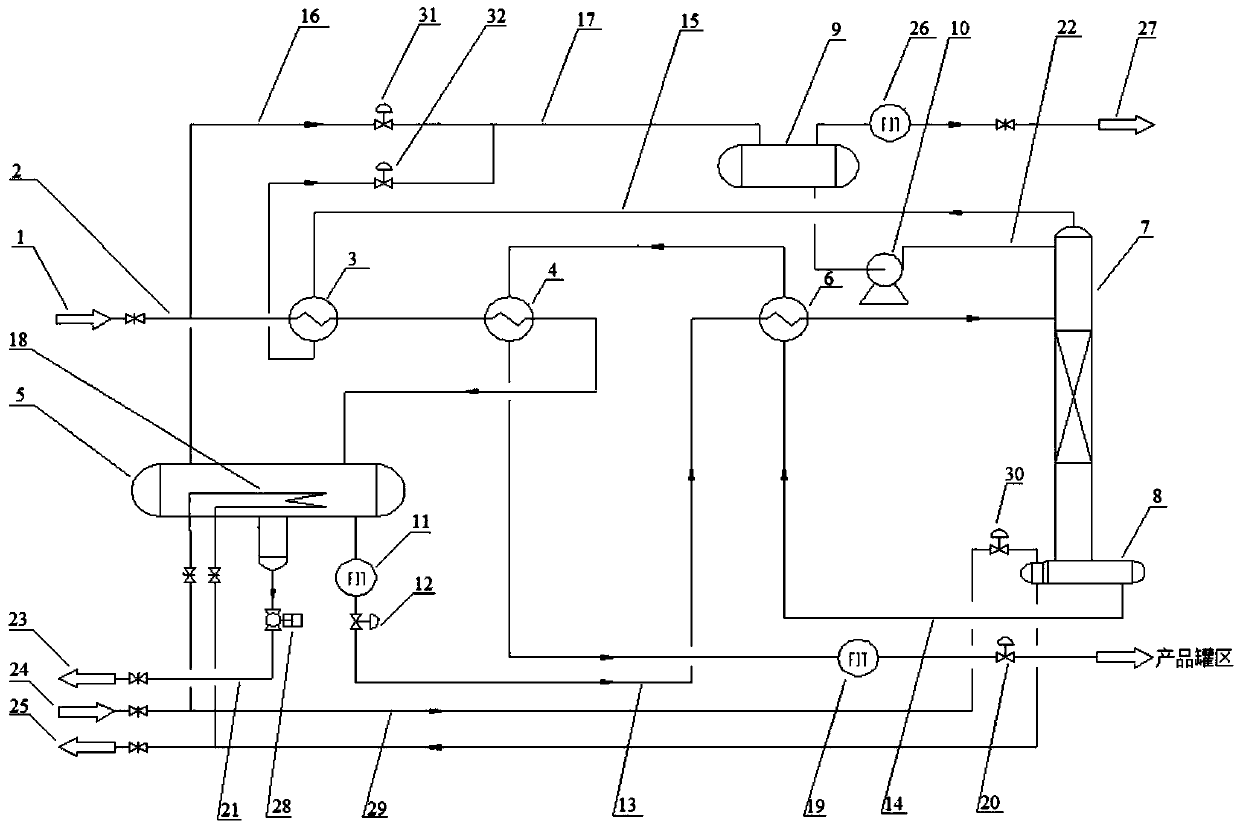

[0034] A low-temperature condensate treatment process of a deoiling and dehydration device in a natural gas treatment plant, comprising the following steps:

[0035] Step 1, the low-temperature condensate 1 is preheated by the non-condensable gas at the top of the condensate stabilization tower 7 in the first-stage gas-liquid heat exchanger 3, and the temperature of the low-temperature condensate 1 increases, and the non-condensable gas at the top of the tower undergoes low-temperature condensation at the same time. Liquid 1 cools down and the temperature decreases;

[0036] Step 2, step 1. The preheated low-temperature condensate 1 is preheated for the second time by the high-temperature stable condensate in the secondary gas-liquid heat exchanger 4, and the temperature rises to 29°C;

[0037] Step 3., the low-temperature condensate 1 after the secondary preheating is separated into gas phase gas, alcohol-containing water and unstabilized condensate oil through the three-phas...

Embodiment 2

[0052] On the basis of Example 1, the temperature of the low-temperature condensate is -15°C, the pressure is 5.5MPa, and the composition is C 1 ~C 11 + , water and methanol, wherein the water content is 16% (mol), the methanol molar content is 19% (mol), C 6 + The content is 46.44% (mol), C 1 ~C 5 The non-condensable gas content was 18.56% (mol).

[0053] The non-condensable gas at the top of the described condensate stabilization tower 7 has a temperature of 45 ° C and a pressure of 0.4 MPa, and the composition is C 1 ~C 11 + and saturated water, in which the saturated water content is 4.92% (mol), C 1 ~C 5 The content is 93.62% (mol), C 6 + The content was 1.46% (mol).

[0054] The preheating and cooling described in step 1 utilizes the heat of the non-condensable gas at the top of the tower and the cooling capacity of the low-temperature condensate 1 at the same time. 45°C is lowered to -5°C; the heating and first cooling described in step ⑤ utilize the coolin...

Embodiment 3

[0059] On the basis of Example 1, the non-condensable gas at the top of the tower described in step ⑥ is mixed with the gas-phase gas of the three-phase separator. Since the condensed liquid in the two is re-equilibrated with gas and liquid, part of the condensed liquid evaporates and absorbs heat, resulting in a temperature drop. , so that the temperature of the mixed gas is lower than the respective temperatures of the non-condensable gas at the top of the tower and the gas phase of the three-phase separator before mixing. When the mixed gas enters the low temperature gas-liquid separator 9 for gas-liquid separation, it needs to be carried out at a low temperature of -10°C to -20°C to ensure that the hydrocarbon dew point of the mixed gas meets the requirements of the fuel gas, and the liquid returns to the top of the tower.

[0060] The stable condensate described in step 5. is heated in the reboiler 8 by the high-temperature heat-conducting oil 24 to form a reboiler, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com