Clutch cover assembly and friction clutch

A friction clutch and clutch cover technology, applied in the field of vehicles, can solve the problems of broken transmission plates, increased friction, wear and corrosion of transmission plates, etc., to achieve the effect of being conducive to stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

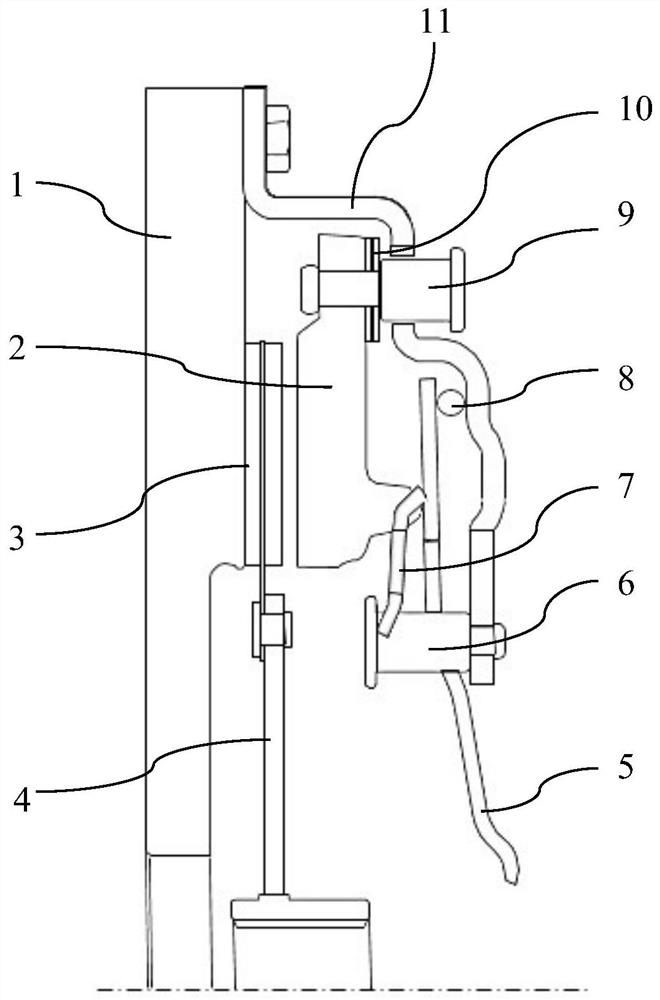

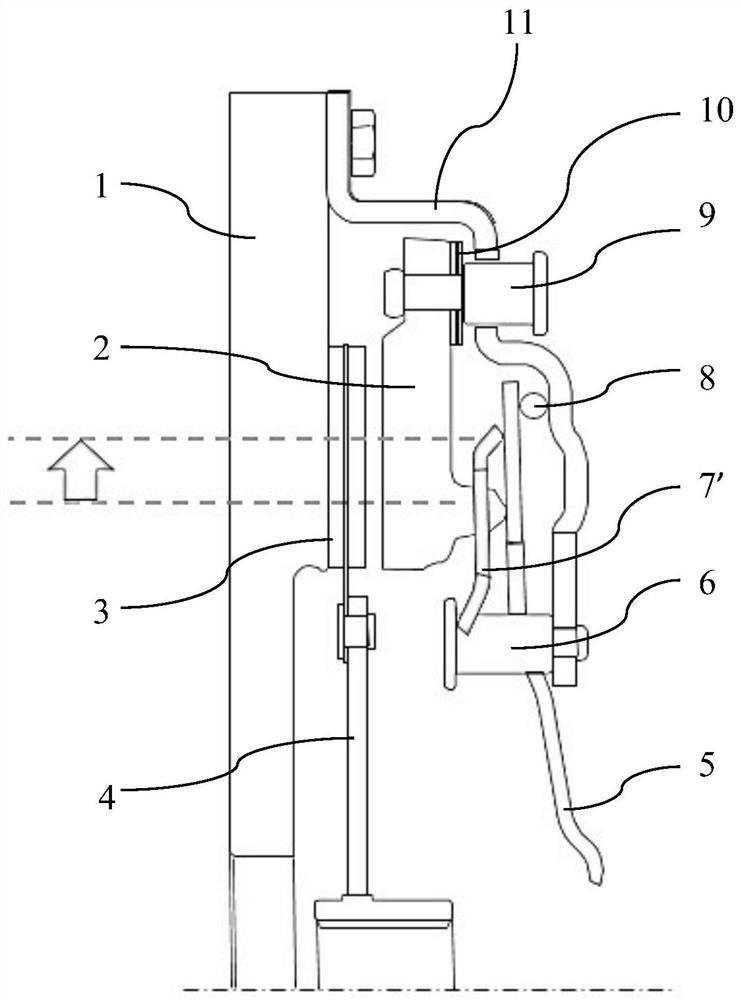

[0025] figure 1 A schematic diagram of a friction clutch according to a preferred embodiment is shown. The friction clutch is used, for example, to transmit torque output from the internal combustion engine in the vehicle to the transmission. The friction clutch is designed here as a normally open friction clutch. The friction clutch has a pairing plate 1, a friction disk 3, and a clutch cap assembly that is arranged in the same axis of rotation, wherein a friction liner is provided on both sides of the axial side of the friction disk 3. Clutch cover assembly includes clutch cover 11, pressure plate 2, and lever spring 5

[0026] The clutch cover 11 and the pairing plate 1 are connected by a bolted outer end. The clutch cover 11 is closed, whereby the clutch cover 11 and the pairing plate 1 constitute a space for accommodating the friction disc 3 and the pressure plate 2. The pairing plate 1 can be connected to an internal combustion engine crank, to transfer the torque of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com