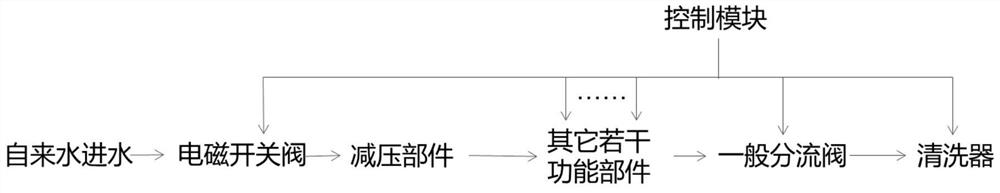

Diverter valve integrated with waterway switch, waterway control method and cleaning waterway

A technology integrating water circuit and diverter valve, applied in valve details, multi-port valve, valve device and other directions, can solve the problems of occupying system control resources, reducing system stability, increasing system control burden, etc., to simplify control methods and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

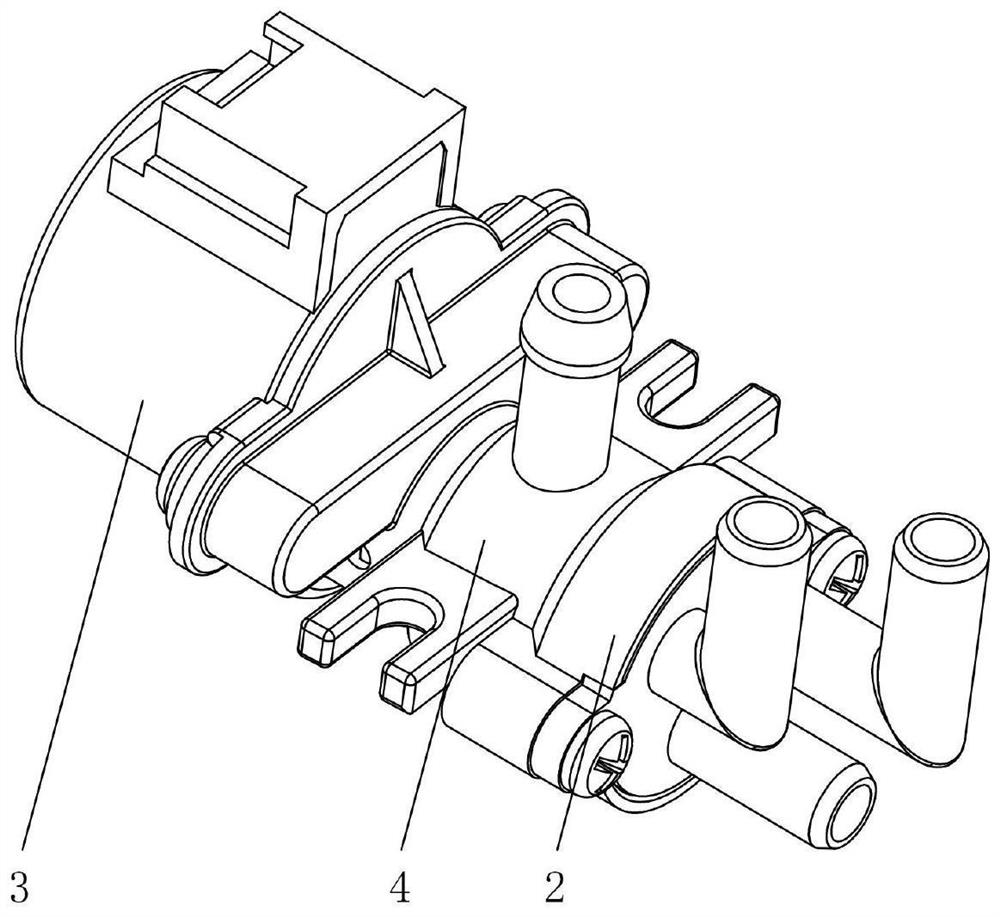

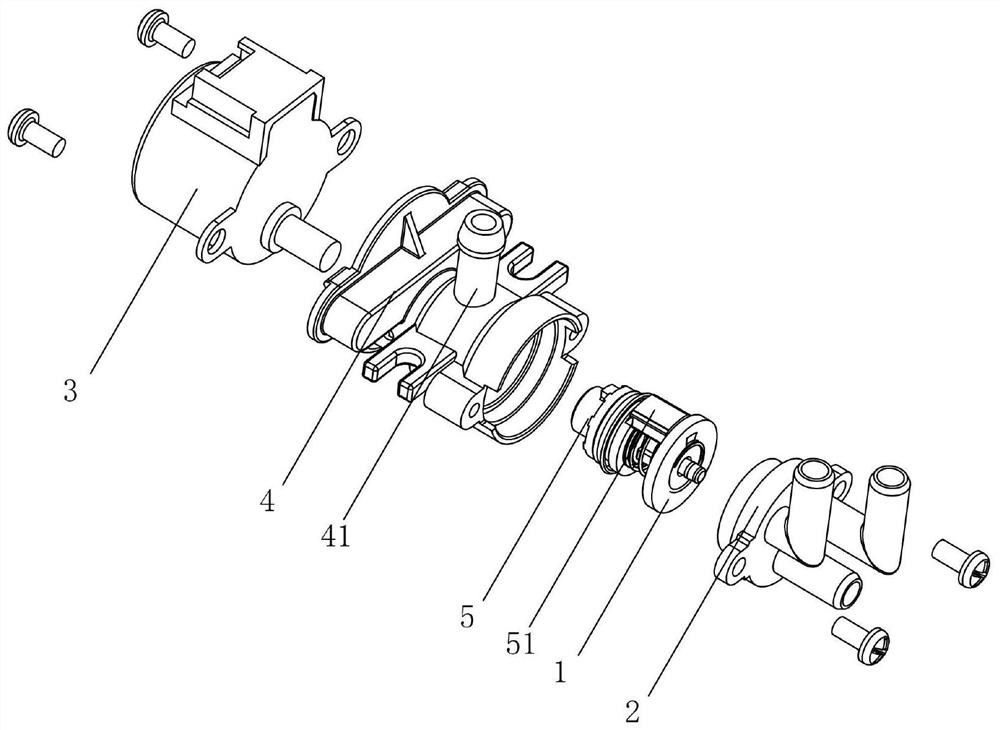

[0035] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, the diverter valve of the integrated waterway switch of this embodiment includes a valve core 1, a valve seat 2 and a rotary drive member 3, and the end surface of the valve seat 2 in contact with the valve core 1 is provided with a plurality of valves communicating with each water passage. The water outlet 21, the end surface of the valve core 1 in contact with the valve seat 2 is provided with a water hole 11 communicating with the water inlet 41, the rotary drive 3 drives the valve core 1 to rotate relative to the valve seat 2, each water outlet 21 and the water outlet The holes 11 are distributed on a ring centered on the relative center of rotation. During the rotation process, the water holes 11 can be connected with each water outlet 21, so that the water flow entered by the water inlet 41 is output to each water channel, realizing use water.

[0036] Different from the existing conventional div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com