A kind of air tightness testing equipment and testing method thereof

A technology for air tightness detection and equipment, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc. The effect of detecting errors, high degree of automation, and shortening the feeding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

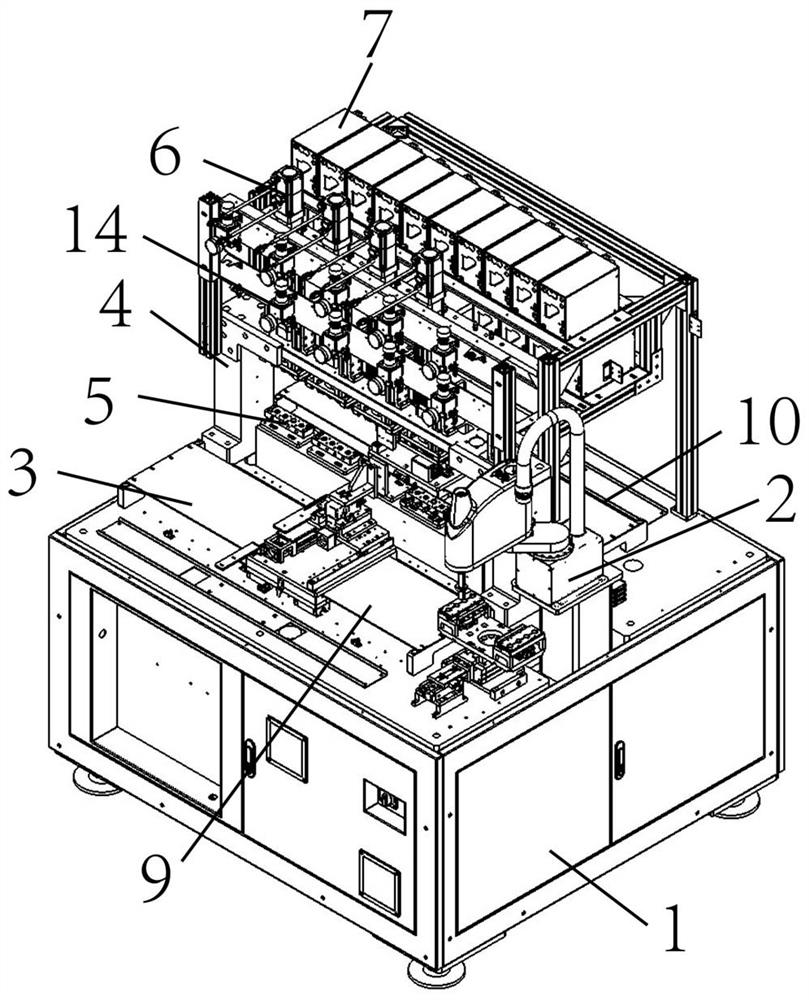

[0067] Such as Figure 1-Figure 7 As shown, a kind of airtightness testing equipment is used to detect the airtightness between the glass in the lens 11 and the metal parts, including a chassis 1, a product feeding device 2, a material shifting device 3 and a detection device 4, said The product feeding device 2, the material shifting device 3 and the detection device 4 are all arranged above the cabinet 1;

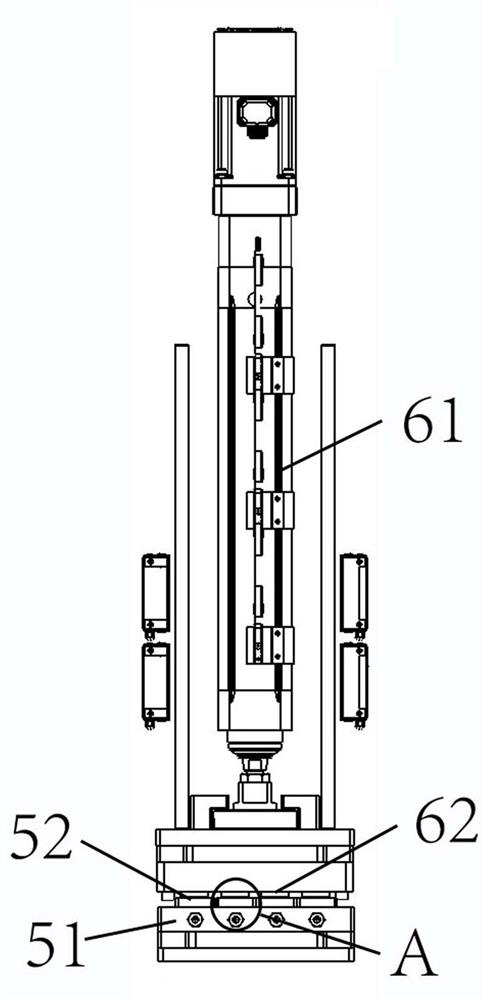

[0068] The detection device includes several second product carriers 5, several pressing devices 6 and several leak testers 7, and the number of the pressing devices is the same as that of the second product carriers, and the pressing devices arranged above the second product carrier and corresponding to the second product carrier;

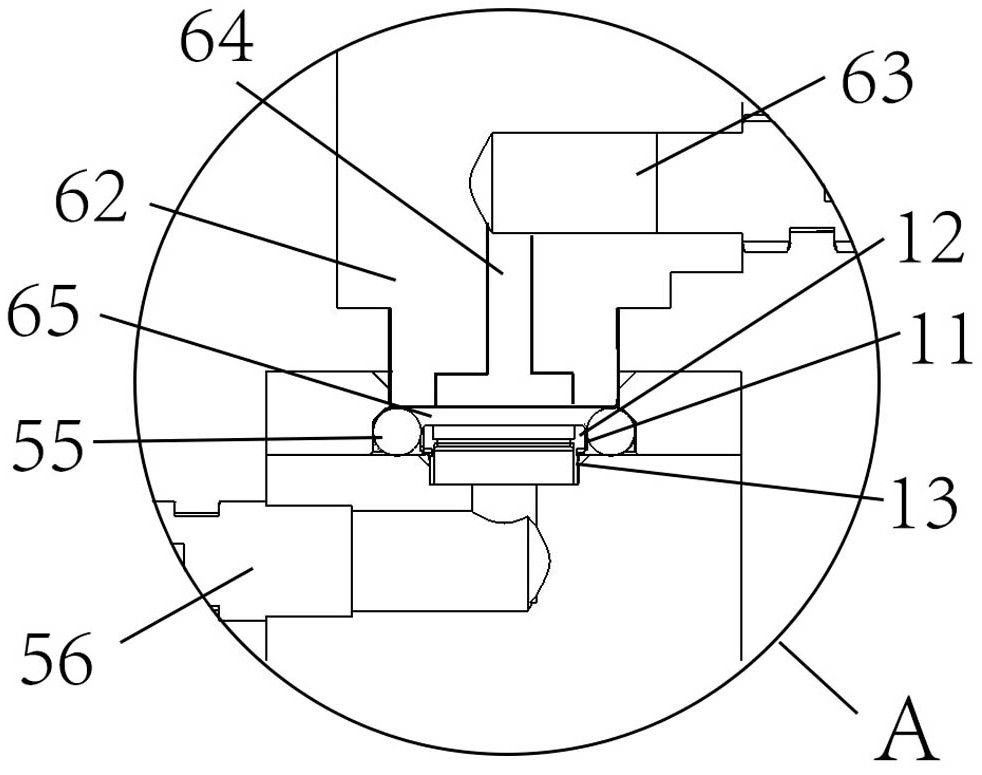

[0069] Each of the second product carriers 5 includes a positioning device 51 and several product positioning devices 52 arranged on the positioning device 51. Each of the product positioning devices is a hollow structure, and each of the pr...

Embodiment 2

[0108] This embodiment is carried out on the basis of the first embodiment above, and the similarities with the above embodiment will not be repeated.

[0109] In this embodiment, a cavity is provided inside the compact.

[0110] Further, the third ventilation pipeline is provided with a three-way leakage hole, and the third ventilation pipeline connected to the leak tester is divided into two branches after passing through the three-way leakage hole, and one branch is connected to the briquette. communicate with the second air duct on the top, and another branch communicate with the cavity inside the briquetting block. Before the test is carried out, it is necessary to close the branch in the tee leak hole that communicates with the cavity in the briquetting block, and then test; when the test data of the lens is abnormal, open the branch in the tee leak hole that is connected to the cavity The branch circuit communicating with the cavity inside the briquetting block is closed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap