Jitter test equipment for small mechanical and electrical products

A technology for electromechanical products and testing equipment, which is applied in the field of jitter testing equipment for small electromechanical products. It can solve the problems of large influence on the surrounding environment, cumbersome operation process, and inconspicuous test results, and achieve small environmental impact, simple operation process, and high test results. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

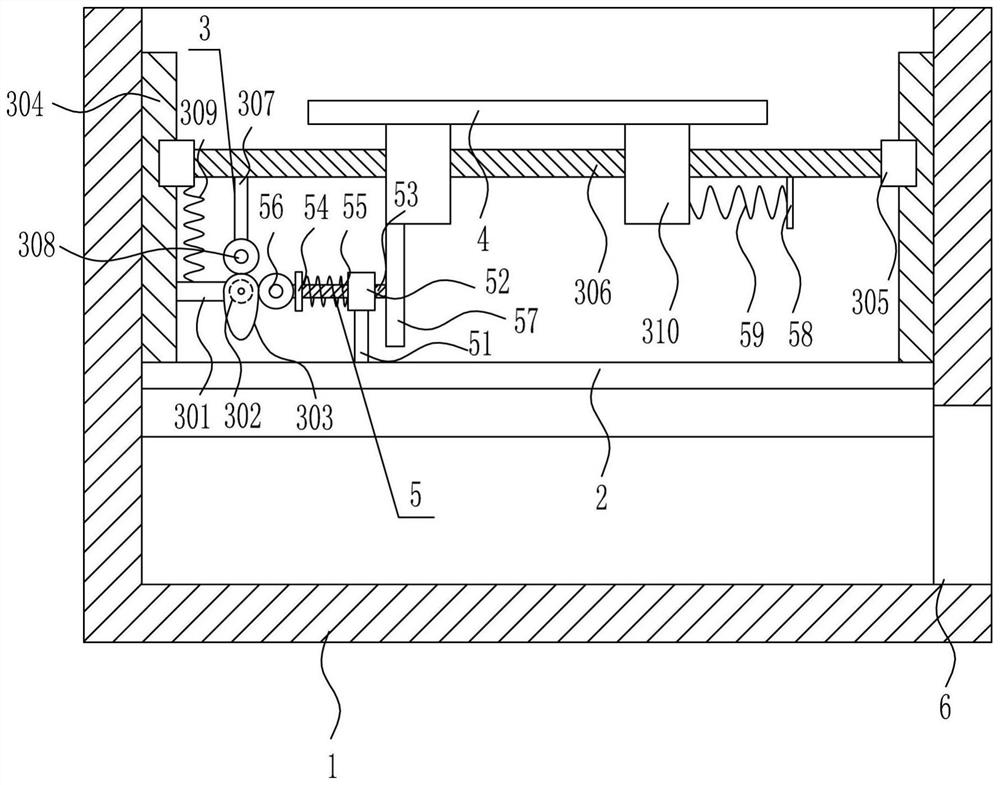

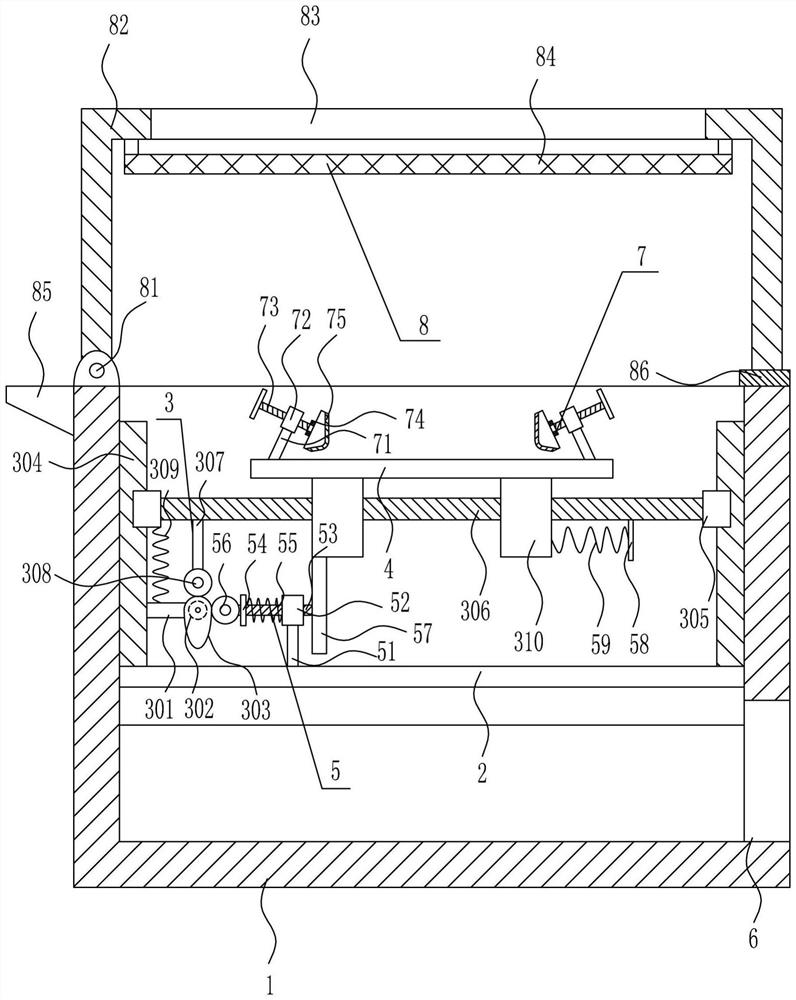

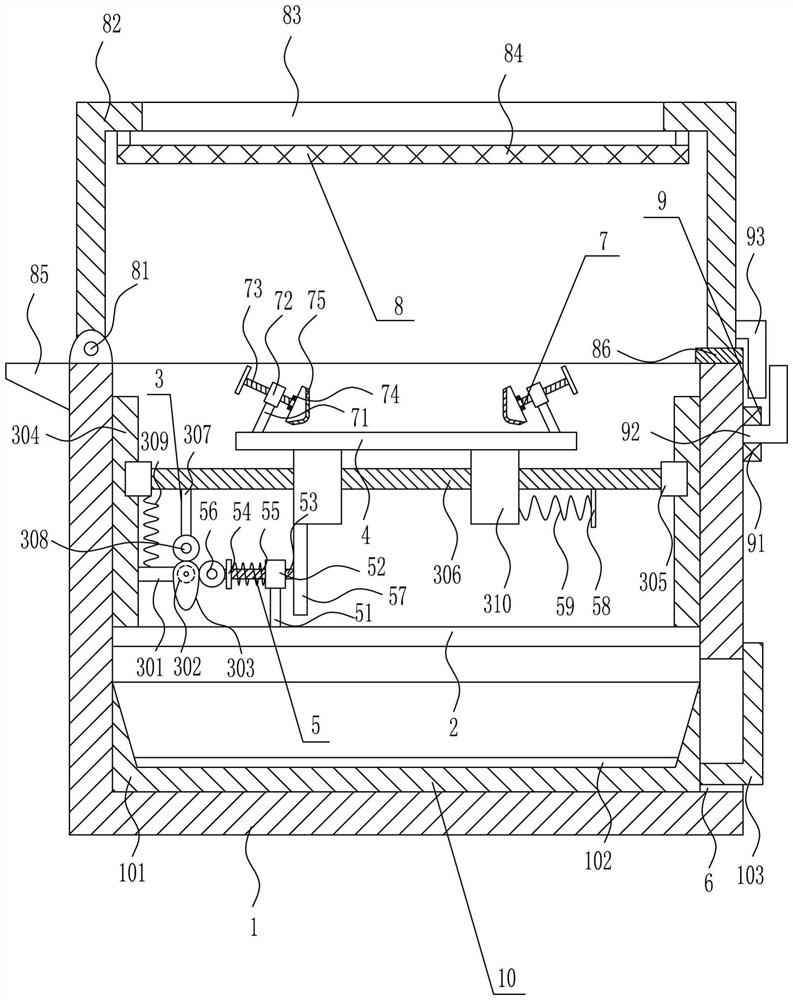

[0029] A jitter test equipment for small electromechanical products, such as Figure 1-3 As shown, it includes a test box 1, a mounting plate 2, a vertical shaking mechanism 3, an operating table 4, and a left and right shaking mechanism 5. The middle part between the left and right side walls of the test box 1 is connected with a mounting plate 2, and the mounting plate 2 is installed There is an up and down shaking mechanism 3, the moving part of the up and down shaking mechanism 3 is connected with an operating table 4, a left and right shaking mechanism 5 is installed on the mounting plate 2, and a first through hole 6 is provided on the right side of the test box 1 bottom.

Embodiment 2

[0031] A jitter test equipment for small electromechanical products, such as Figure 1-3 As shown, it includes a test box 1, a mounting plate 2, a vertical shaking mechanism 3, an operating table 4, and a left and right shaking mechanism 5. The middle part between the left and right side walls of the test box 1 is connected with a mounting plate 2, and the mounting plate 2 is installed There is an up and down shaking mechanism 3, the moving part of the up and down shaking mechanism 3 is connected with an operating table 4, a left and right shaking mechanism 5 is installed on the mounting plate 2, and a first through hole 6 is provided on the right side of the test box 1 bottom.

[0032] The up and down shaking mechanism 3 includes a first pole 301, a motor 302, a cam 303, a slide rail 304, a slide block 305, a first slide bar 306, a second pole 307, a first contact wheel 308, a first return spring 309 and The first sliding sleeve 310, the left side of the top of the mounting p...

Embodiment 3

[0034] A jitter test equipment for small electromechanical products, such as Figure 1-3 As shown, it includes a test box 1, a mounting plate 2, a vertical shaking mechanism 3, an operating table 4, and a left and right shaking mechanism 5. The middle part between the left and right side walls of the test box 1 is connected with a mounting plate 2, and the mounting plate 2 is installed There is an up and down shaking mechanism 3, the moving part of the up and down shaking mechanism 3 is connected with an operating table 4, a left and right shaking mechanism 5 is installed on the mounting plate 2, and a first through hole 6 is provided on the right side of the test box 1 bottom.

[0035] The up and down shaking mechanism 3 includes a first pole 301, a motor 302, a cam 303, a slide rail 304, a slide block 305, a first slide bar 306, a second pole 307, a first contact wheel 308, a first return spring 309 and The first sliding sleeve 310, the left side of the top of the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com