Wide-range air valve visual recognition device

A visual recognition and large-scale technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as air valve dumping, unrecognizable air valves, and instability of work vehicles, and achieve accurate visual recognition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

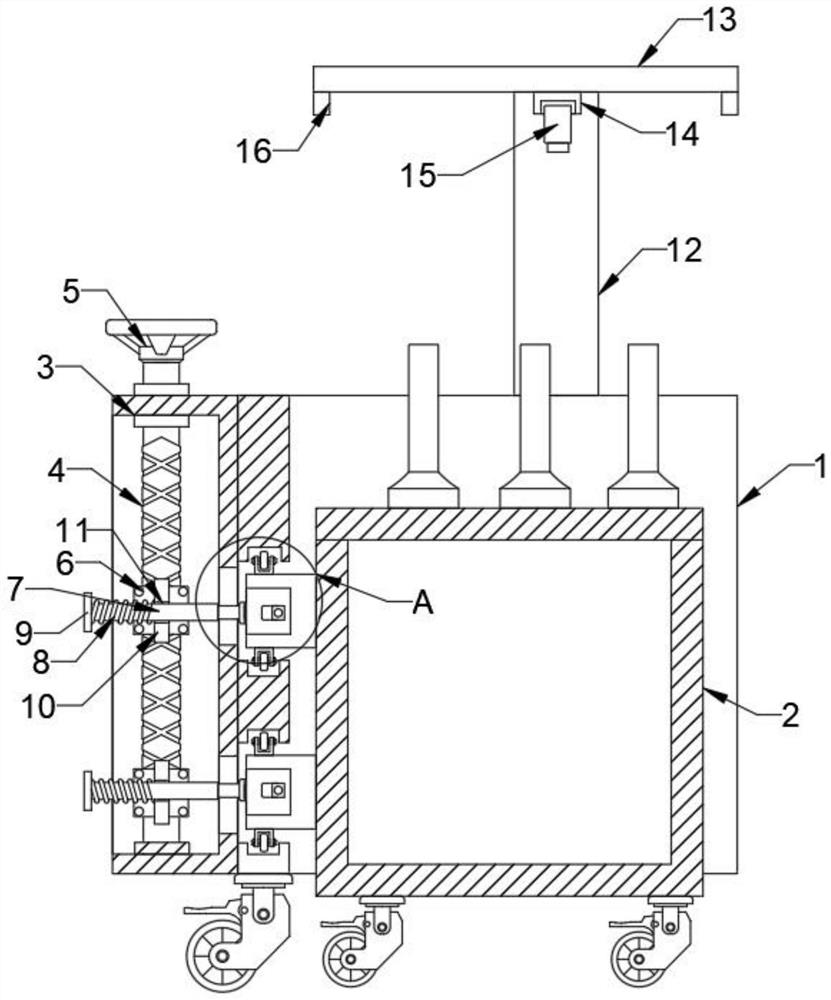

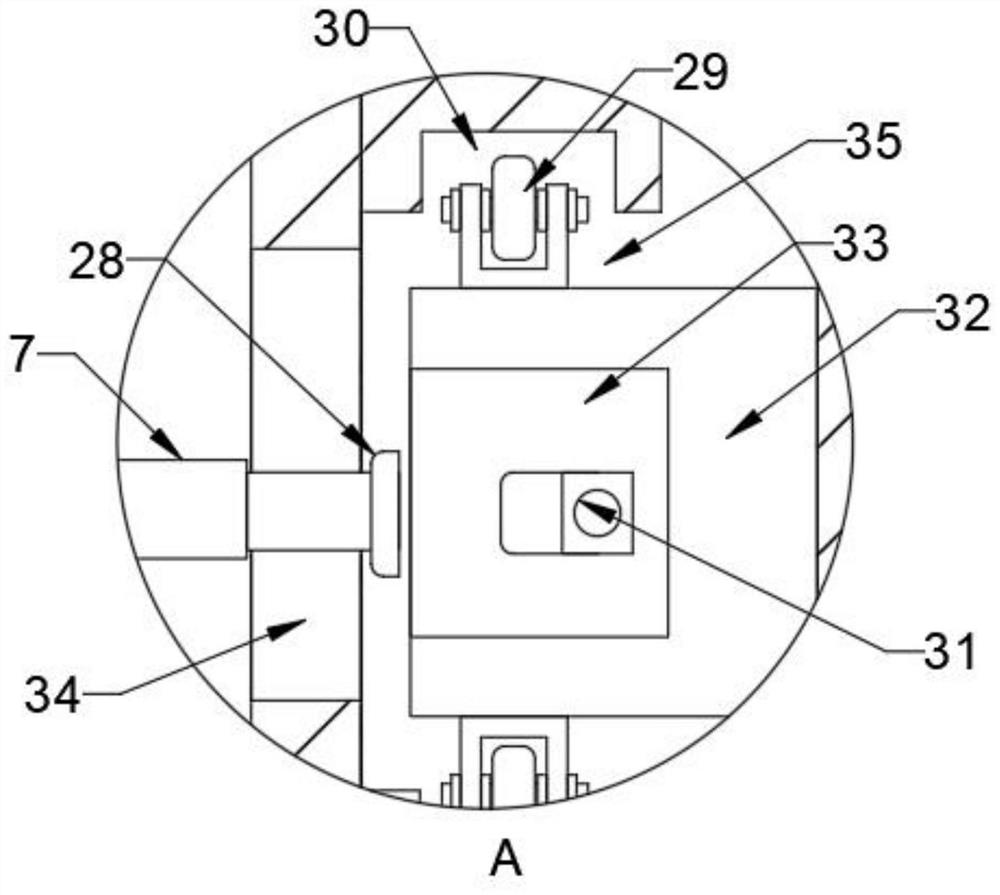

[0026] refer to Figure 1-4 , comprising a main body 1, one side of the main body 1 is fixedly connected with a detection cabinet 17, the top of the detection cabinet 17 is fixedly connected with a bearing tube 12, the inner side of the bearing tube 12 is provided with a movable rod 18, and the top of the movable rod 18 passes through the bearing groove 24 It runs through the top of the bearing tube 12, and the top of the movable rod 18 is fixedly connected to the top plate 13, the bottom of the top plate 13 is fixedly connected to the linear slide module 14, and the bottom of the linear slide module 14 is slidably connected to the visual camera 15, and The bottom of the top plate 13 is fixedly connected with a light source 16, one side of the main body 1 is provided with a working vehicle 2, and one side of the main body 1 is fixedly connected with a frame body 3, and the inner side of the frame body 3 is rotatably connected with a screw rod 4, and the upper part of the screw ...

Embodiment 2

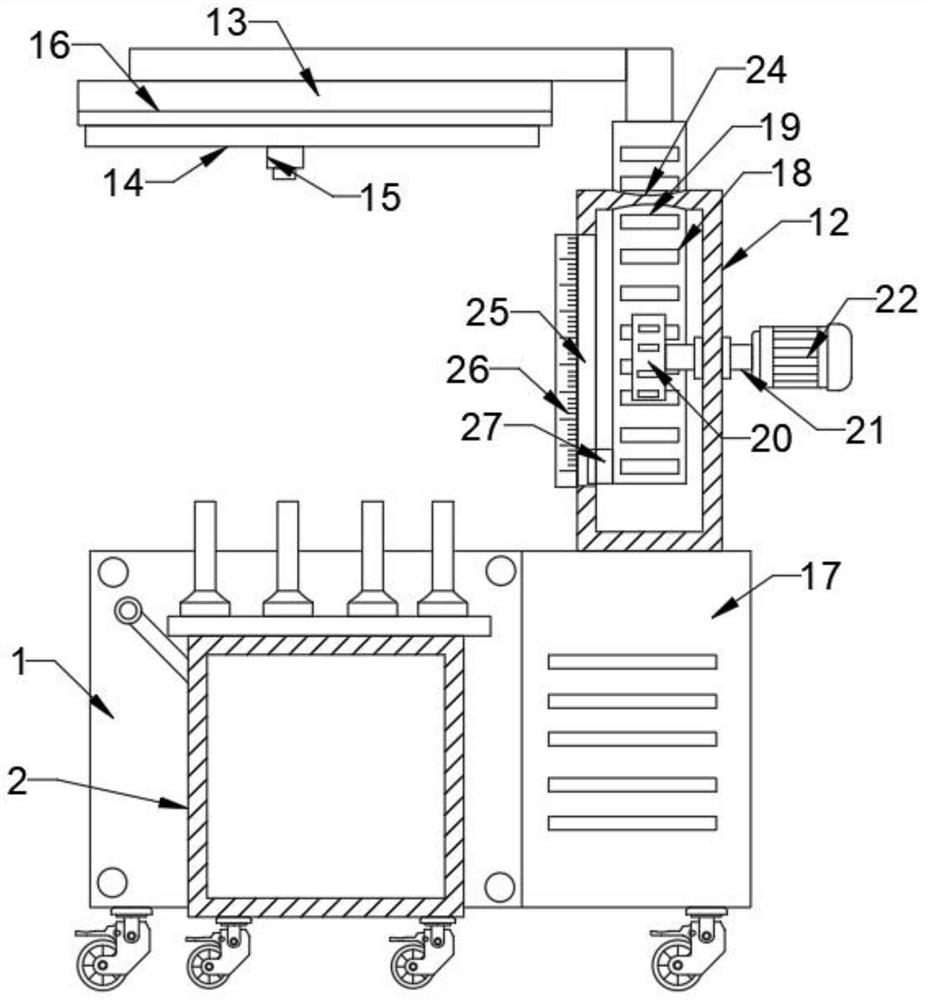

[0029] refer to Figure 1-4 One side of the outer wall of the carrying tube 12 is fixedly connected with a drive motor 22 by bolts, and the inner side of the carrying tube 12 is provided with a rotating rod 21, and one end of the rotating rod 21 is fixedly connected with a gear 20, wherein the other end of the rotating rod 21 is passed through a bearing The sleeve runs through the side wall of the bearing tube 12 and is connected to the output shaft of the drive motor 22. The movable rod 18 is fixedly connected with the rack 19, and the rack 19 is connected to the gear 20 through the engagement between the teeth. One side of the bearing tube 12 A vertical groove 25 is provided, and a slider 27 is fixedly connected to one side of the outer wall of the movable rod 18, and the slider 27 is slidingly connected to the inner wall of the bearing tube 12 through the vertical groove 25, and the outer wall of the bearing tube 12 is close to the side of the vertical groove 25. A scale 26...

Embodiment 3

[0032] refer to Figure 1-4 The bottom end of the screw rod 4 is rotationally connected with the inner bottom of the frame body 3 through a rotating shaft, and the other end of the screw rod 4 runs through the top of the frame body 3 through a bearing sleeve, and the extension end of the screw rod 4 is fixedly connected with a handle 5, two The top and the bottom of each limit block 32 are all connected with a pulley 29 through the rotation of the rotating shaft, and the pulley 29 is connected by sliding between the inner wall of the chute 30 and the support groove 35, and the pulley 29 is used to slide in the chute 30, and then can further Ensure the stability of the work vehicle 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com