Improved buzzer and manufacturing process thereof

A manufacturing process and buzzer technology, which is applied in the direction of instruments, sounding devices, etc., can solve the problems of current reduction, impact of buzzer operation, and low production efficiency, so as to increase winding friction, ensure electrical connection performance, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

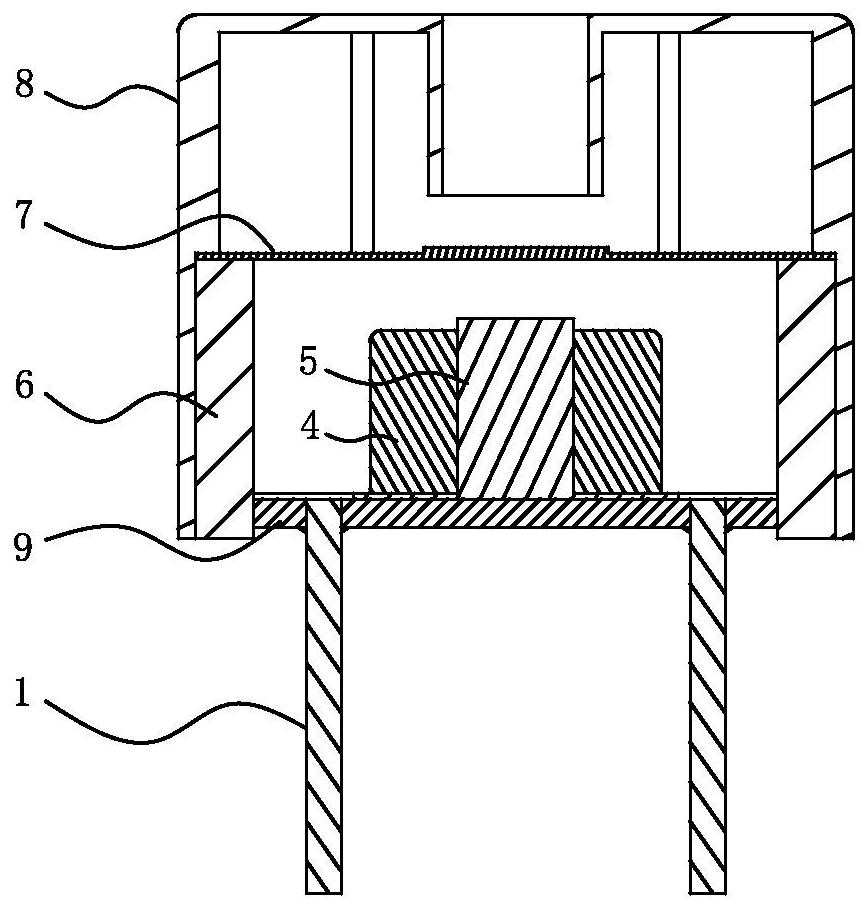

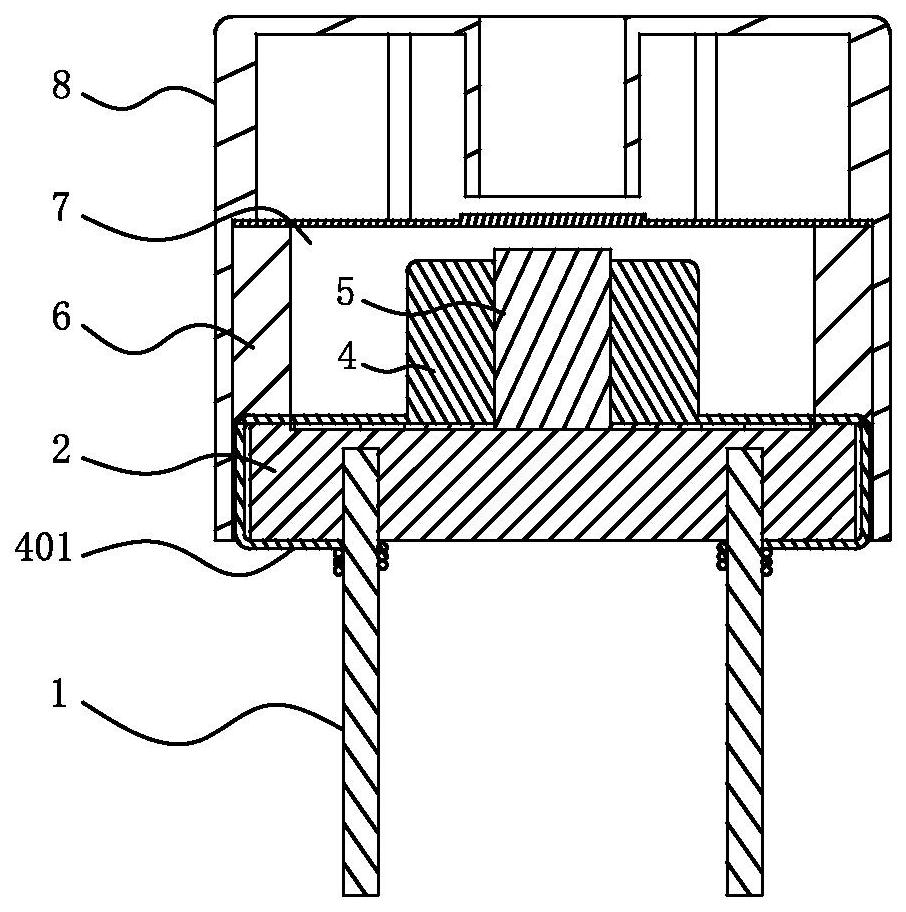

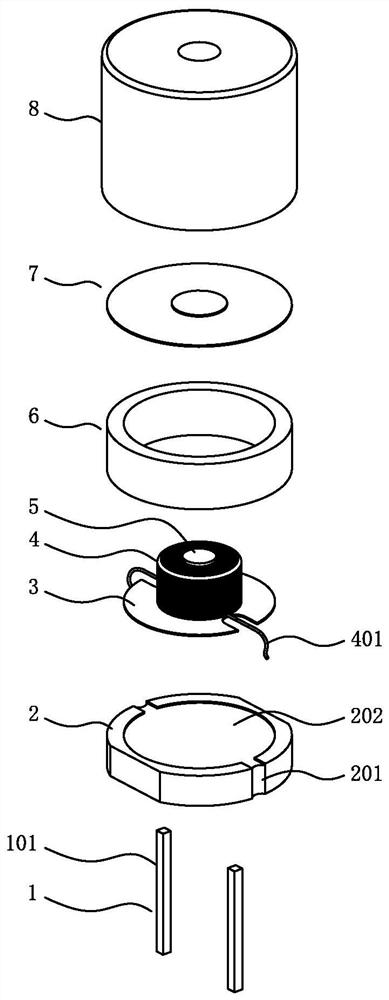

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] see Figure 1-Figure 3 , the buzzer involved in this embodiment includes a pin 1, a bottom cover 2, and a coil set 4; the pin 1 and the coil set 4 are respectively arranged on the bottom cover 2; the beginning and the end of the coil set 4 are respectively wound on the pin 1 , to directly electrically connect the corresponding pin 1. Compared with the traditional buzzer, the improved buzzer cancels the setting of the PCB board 9, and the pin 1 is directly electrically connected with the coil group 4. This structure can cancel the related welding process, and there is no need to fix the PCB board 9. Glue filling saves the process of waiting for the glue to solidify, so that the production of the buzzer can realize uninterrupted assembly line production, which greatly improves the production efficiency of the buzzer; in addition, pin 1 is directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com