Double Angle Horizontal Rotary High Voltage Isolation Switch

A high-voltage isolating switch and horizontal rotating technology, which is applied in the field of double-angle horizontal rotating high-voltage isolating switches, can solve the problems that products are prone to sticking, incorrect position status, and increase costs, so as to avoid the problem of bearing seat corrosion, The product has the effect of accurate opening and closing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

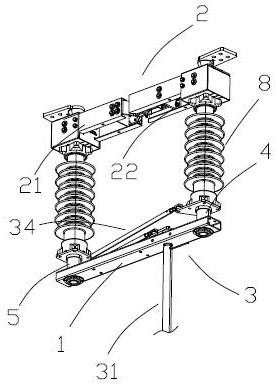

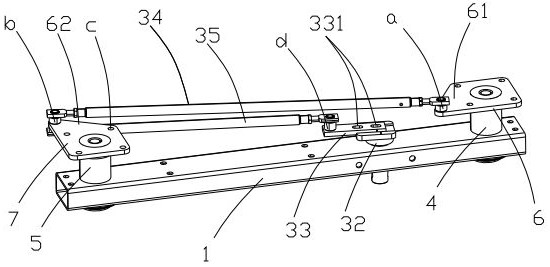

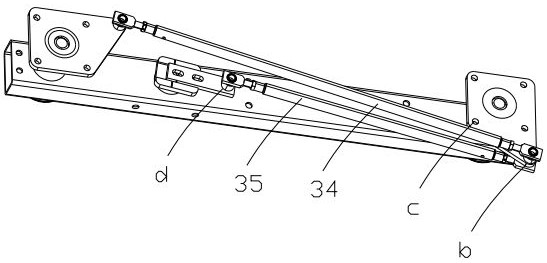

[0031] Such as Figure 1-3 As shown, a double-angle horizontal rotary high-voltage isolating switch includes a support base 1, a conductive device 2 and a transmission system 3, and the two ends of the support base in the length direction are respectively provided with a first bearing seat 4 and a second bearing seat 5 , the upper end of the first bearing seat is provided with a rotatable first connecting plate 6, and the upper end of the second bearing seat is provided with a rotatable second connecting plate 7; the conductive device is arranged above the first connecting plate and the second connecting plate, The conductive device includes a contact finger side conductive device 21 and a contact side conductive device 22, the contact finger side conductive device is connected to the first connecting plate through an insulator 8, and the contact side conductive device is connected to the second connecting plate through an insulator; the transmission system Including the trans...

Embodiment 2

[0046] Similar to Embodiment 1, the difference lies in the distance from the hinge point of the first connecting rod and the first connecting plate to the axis of the first bearing housing, the distance from the hinge point of the first connecting rod and the second connecting plate to the second The distance from the axis of the bearing seat, the distance from the hinge point of the second connecting rod and the second connecting plate to the axis of the second bearing seat, and the ratio of the distance from the hinge point of the second connecting rod and the crank arm to the axis of the third bearing seat can be adjusted as 2:2:2:2 1 / 2 , 1:1:1:1 combination;

[0047] Moreover, the third hinge point is not provided, and the operating mechanisms with different rotation angles are adapted by changing the length of the crank arm. Matched with it, the crank arm includes two types, and the ratio of the hinge point of the two types of crank arms to the axis of the third bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com