Ultrahigh current monitoring and processing system

A current monitoring and ultra-high technology, which is applied in the direction of measuring devices, electrical components, electrical equipment structural parts, etc., can solve the problems of increasing measurement errors, low current detection accuracy, and difficulty in measuring currents containing DC components. Achieve the effects of weakening power, avoiding interference, and avoiding errors caused by inaccurate measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

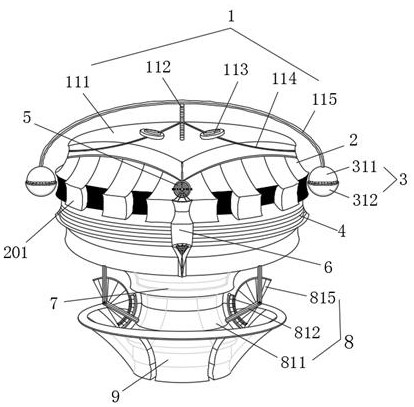

[0045] see figure 1, an ultra-high current monitoring and processing device, comprising a spring mechanism 1, the interior of the spring mechanism 1 includes a movable plate 111, an elastic band 114 is connected through the top side wall of the movable plate 111, and the side wall of the elastic band 114 runs through A movable ring 113 is connected, a compression spring 112 is connected through the middle part of the top side wall of the movable plate 111, an elastic spring 115 is connected through the top of the compression spring 112, and a rolling mechanism 3 is connected through the bottom end of the elastic spring 115. The interior includes a movable ball 311, the side wall of the movable ball 311 is connected with a hemispherical shell 312, the bottom side wall of the elastic mechanism 1 is connected with a movable block 2, and the side wall of the movable block 2 is connected with a pressing block. 201, the bottom end of the movable block 2 is connected with a laminated...

Embodiment 2

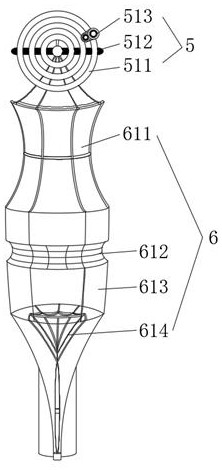

[0050] see Figure 1-2 , an ultra-high current monitoring and processing device, comprising a spring mechanism 1, the interior of the spring mechanism 1 includes a movable plate 111, an elastic band 114 is connected through the top side wall of the movable plate 111, and the side wall of the elastic band 114 runs through A movable ring 113 is connected, a compression spring 112 is connected through the middle part of the top side wall of the movable plate 111, an elastic spring 115 is connected through the top of the compression spring 112, and a rolling mechanism 3 is connected through the bottom end of the elastic spring 115. The side wall of the bottom end of 1 is connected with a movable block 2, the side wall of the movable block 2 is connected with a pressing block 201, the bottom of the movable block 2 is connected with a laminated body 4, and the side wall of the laminated body 4 is The down-pressing mechanism 6 is connected through, and the inside of the down-pressing...

Embodiment 3

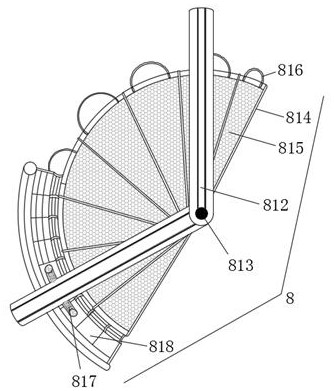

[0053] see figure 1 and image 3 , an ultra-high current monitoring and processing device, comprising a spring mechanism 1, the interior of the spring mechanism 1 includes a movable plate 111, an elastic band 114 is connected through the top side wall of the movable plate 111, and the side wall of the elastic band 114 runs through A movable ring 113 is connected, a compression spring 112 is connected through the middle part of the top side wall of the movable plate 111, an elastic spring 115 is connected through the top of the compression spring 112, and a rolling mechanism 3 is connected through the bottom end of the elastic spring 115. The side wall of the bottom end of 1 is connected with a movable block 2, the side wall of the movable block 2 is connected with a pressing block 201, the bottom of the movable block 2 is connected with a laminated body 4, and the side wall of the laminated body 4 is A pressing mechanism 6 is connected through it, and a rotating mechanism 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com